Manual mold silicone rubber for mold design or product duplication

Product Details

FAX: 86 755 89948030

TEl: 86 755 89948013

if you need more information ,you can contact with Miss Ava,

To handle this situation depends on different cases. Under the condition of an available vacuum pumping machine, mix the silicon rubber and curing agent evenly and then take it to vacuum chamber to deair. If without a vacuum pumping machine, reduce the amount of the curing agent properly. For example, change the mixing ratio of the silicon rubber and the curing agent from former 4% to 1%-2%. In this way, the pre-crosslinking time of silicon rubber will slow down, so the air in the mold will be eliminated gradually to reduce the air bubbles.

What should we do when the air bubbles appeared in the process of mold making?

5) Frequently asked questions for Silicon rubber for manual mold

.

Note2: The manual mold silicon is applied to small products or products with fine patterns. The mold for the fine detailed and small products should be made of soft silicon to protect the products from easy breaking when demoulding. If large product duplication or fabrication, the mold should be made of higher hardness silicone rubber so that the products made will not deform.

Note1: Our company does not recommend you to add silicone oil. If a special soft silicon mold or fine detailed and complex patterns product is required, 5%-10% silicone oil can be added to soften

the mold for easier demould.

First and foremost, you should process and prepare model or product which is duplicated, and then you should combine certain amount of the silicon rubber with 2-3% solid curing agent. Mixing them

evenly and prepare for using. Manual Mold Silicon Rubber can be solidified and formed in 2-3 hours.

.

4) Operation Instruction for Manual Mold Silicone rubber:

Manual Mold Silicon Rubber has the features of resistance to deformation, good tensile strength and low shrinkage. And times of reproduction are up to customers need.

3) Manual Mold Silicon Rubber features:

.

Manual Mold Silicon Rubber for is mainly applicable to manual mold design, PVC plastic molds, cement product molds, electronic toy cars, melting point alloy molds, alloy toy craftworks, plastic toy craftworks, gifts and stationery, large statues, duplication of cultural relics, shoe mold fabrication, pad printing positioning, shock resistance for electronic equipments, etc.

2) Applications for manual molding silicon rubber:

.

manual molding silicon rubber is flowing liquid with consistent quality in whatever color. It consists of two components, wherein component A is silicone rubber, and component

B is curing agent or vulcanizing agent. Firstly process and prepare the model mold or the product to be duplicated, take certain amount of the silicone rubber, add 2-3% curing agent, and mix evenly

for use. One mold pair can be solidified and formed in 2-3 hours. The formed mold can be used repeatedly without deformation and water shrinkage and with high temperature resistance, thereby

providing fast duplication of the product with product shrinkage 2. Manual mold silicon is mainly applicable to manual molds and small number of product duplication.

1) Description for manual molding silicon rubber:

Manual Mold Silicon advantages:

1.Resistance to deformation

2.good tensile strength

3.Low shrinkage

4.Easy to operation

- Color::many

- CERTIFICATE::ISO9000 9001 SGS ROHS

- Model Number:528 540 570Hongye silicon rubber

- Brand Name:Hong Ye Silicon Rubber

- Place of Origin:Guangdong China (Mainland)

- Country:China (Mainland)

- telephone:86-755-89948013

| Delivery Time: | Within 3 days after we get your bank receipt |

| Package: | 25kg/drum 200kg/drum |

| Supply Ability: | 8 Ton per Day |

| Minimum Order Quantity: | 200 Kilogram |

| Payment Terms: | L/C,T/T |

| Port: | Shenzhen |

| FOB Price: | US $6.3 - 8.3 |

| Color:: | many |

| CERTIFICATE:: | ISO9000 9001 SGS ROHS |

| Model Number: | 528 540 570Hongye silicon rubber |

| Brand Name: | Hong Ye Silicon Rubber |

| Place of Origin: | Guangdong China (Mainland) |

You may also like

- liquid silicone rubber

- rtv silicone rubber

- silicon rubber

- molding silicone rubber

- making silicone rubber

- printing silicone rubber

- rubber silicone

- silicone rubber gasket

- mould silicone rubber

- mold silicone rubber

- silicone rubber product

- liquid silicon rubber

- silicone rubber seal

- silicone rubber pad

- silicone rubber keypad

- silicone rubber mold

- silicone rubber ring

- quality silicone rubber

- flexible silicone rubber

- silicone rubber

Send inquiry / quota request to Manual mold silicone rubber for mold design or product duplication

Relate products of Manual mold silicone rubber for mold design or product duplication

QIANTAI is a professional heat transfer manufacturers in China, which includes PET heat transfer film, DTF pet film, Heat transfer vinyl, Heat transfer sticker, Hot Melt Powder. They are widely used in heat transfer and the textile industry. Our pet printing film are certified ...

The 750ml Special Design Dark Color Sparking Wine Bottle is a sleek and stylish choice for those looking to add a touch of sophistication to their special occasion or celebration. Made from high-quality glass, this black champagne bottle features a unique and eye-catching dark ...

Come From Heze Rising Glass Co.,Ltd

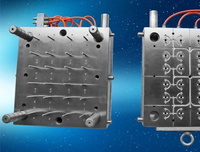

Plastic Mould Industry The industrial plastic injection mold is replacing metal products in many fields of industrial applications to meet the requirement of lightweight industrial equipment and cost-reduction. Green Vitality has accumulated many experiences over the years in ...

Come From Green Vitality Industry Co., Limited

To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, machining cost and time will be saved and the production efficiency increased. Green Vitality concerns a lot on mold cooling system and production stability. ...

Come From Green Vitality Industry Co., Limited

If the weight of each fan blade is not balanced, large vibration, high noise, and large wear of the rotating shaft will occur during high-speed rotation, which not only seriously affects product performance, but also The lifetime will also be greatly reduced. Therefore, fan ...

Come From Green Vitality Industry Co., Limited

Consumer electronics is very popular in our daily life. It consists of many different plastic parts, pcb boards, wires, battery and some metal parts. To produce the plastic components of consumer electronics, we need manufacture the plastic injection molds first. Consumer ...

Come From Green Vitality Industry Co., Limited

HQ accumulated years of experience in aluminium die casting products and accumulated technical know-how to help customers choose the properest processing methods and materials. ALUMINIUM CASTING PRODUCTS APPLICATION Heat sink Impeller If you want to know more kinds of custom ...

The Three Part Syringe Plunger from PLUSLINK is a durable and easy-to-use device designed to help inject medication into the body accurately and safely. It is constructed from three separate parts made from medical-grade plastic, allowing for easy maintenance, cleaning and ...

Come From LINKPLUS PTE. LTD.

It is designed for various types of three-part syringe barrel.including luer slip, luer lock and dual-structural syringe. (1ml, 2ml, 2.5ml, 3ml, 5ml, 10ml, 20ml, 25ml, 30ml, 50ml, 50ml Catheter Tip, 60ml Catheter Tip, 100ml, 150ml) It consists of three main components: the ...

Come From LINKPLUS PTE. LTD.

LINKPLUS provide precision molds used in manufacturing of each components of the various syringes such as disposable syringe, Insullin syringe, safety syringe, AD syringe. Including barrel, plunger, gasket. It\'s customizable according to customer production need. Our syringe ...

Come From LINKPLUS PTE. LTD.