Vertical Grinding Mills

Specifications

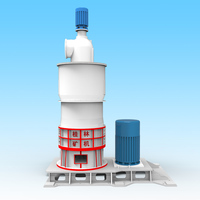

GKLM seriesvertical grinding mill

Guilin Mining Machinery

High yield, low energy consumption;

Two-way buffering structure design of hydraulic cylinder, work more smoothly;

Grader adopts 5 groups of horizontal grading wheel structure, dynamic balance correction, high classification accuracy;

Advanced hydraulic station, cooling station system;

Intelligent control.

The verticaltower mill grinding is a kind of advanced grinding equipment designed and developed on the basis of the extensive use of advanced technology at home and abroad, combined with many years of various mill machine production experience. It is an ideal equipment for grinding industry, which integrates crushing, drying, grinding and grading transportation. It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic mineral industry and so on. It is used to grind lump, granular and powdery raw materials into the required powder materials.

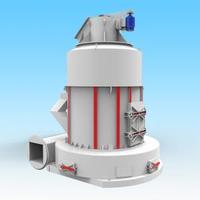

The main structure of thecentrifugal grinding mill

Vertical grinding machine mainly consists of powder separator, grinding roller device, grinding disc device, the pressure device, reducer, motor, shell and so on. The separator is a highly efficient and energy saving powder separator. Grinding roller is used to crush and crush materials. The millstone is fixed on the output shaft of the reducer and is the place where the grinding roller compacts the material. The pressurizing device is a component for grinding roller to provide enough pressure to crush material.

Working principle of the vertical grinding machine

When the vertical grinding machine is working normally, the motor drives the grinding disc to rotate through the reducer, and the material falls from the feed inlet to the center of the grinding disc through the lock air feeder. With the rotation of the grinding disc, the material moves to the edge of the grinding disc under the action of the centrifugal force. Through the ring groove on the grinding disc, the material is crushed by the roller rolling. The crushed material is brought up at the edge of the grinding disc by high-speed airflow from the wind ring and the large particles fall directly onto the grinding disc to re-ground. When materials in the air flow pass the upper separator, under the action of rotating rotor, the coarse powder falls from the cone bucket to the grinding disc and is re-ground. The qualified fine powder goes out with the airflow and is collected by the dust collecting device, that is, the product. Materials containing moisture are dried in contact with hot air flow. By adjusting the hot air temperature, it can meet the requirements of different humidity materials and achieve the required product moisture. By adjusting the separator, the required thickness of different products can be achieved.

Main features of the vertical grinding machine

1.Low investment cost

Due to the integration of crushing, drying, grinding and grading, the system is simple and the layout is compact. The area is about 50% of the ball milling system, and it can be arranged in the open air. Therefore, the investment cost can be reduced greatly.

2.Low operating cost

(1)High grinding efficiency : using the grinding roller to directly crush the material on the grinding disk, low energy consumption, and 30% ~ 40% less energy consumption than ball grinding system.

(2)Less abrasion: longer service life and less wear due to the fact that the grinding roller does not contact the grinding disc directly during work and that the grinding roller and the lining plate are made of high quality materials.

3. Strong drying ability

Because the hot air directly contacts with the material in the grinding, it has strong drying ability and saves energy. By adjusting the hot air temperature, it can meet the requirements of different humidity materials.

4. Easy operation

(1)The system is equipped with automatic control system, which can realize remote control and easy operation.

(2) Vertical grinding machine is equipped with equipment to prevent direct contact between roller sleeve and disc liner to avoid destructive impact and severe vibration.

5. Stable product quality

Because the material stays in the grinding for a short time, it is easy to detect and control the product granularity and chemical composition, reduce the repeated grinding, and stabilize the product quality.

6. Convenient maintenance

Overhauling the oil cylinder, turning the rotating arm, replacing the roll sleeve and liner plate is convenient and quick, reducing losses in downtime.

7. environmental protection

Vibration is small, noise is low, and the whole equipment is sealed, the system works under negative pressure, no dust spillover, clean environment, and meets the national environmental protection requirements.

The process flow of the vertical grinding machine

According to the location of humidifying tower and dust collector, thehigh pressure grinding mill has two different layout schemes, namely, the three fan system and the double fan system. A cyclone collector is used for the collection of products. This arrangement reduces the working negative pressure of the system and the amount of gas passing through the dust collector. The electric dust collector can also be replaced by the bag dust collector as the final dust collector. The dust collector can be the electric dust collector or the bag collector, and the grinding gas is directly entered into the dust collector. The system reduces the number of equipment and simplifies the system configuration.

Application field

Preparation of coal powder for special steel mills, power plants and cement plants and production of a large amount of powder for coal gangue;

Desulphurized limestone powder for the special power plant; The production and preparation of hundreds of mineral bulk powders with various hardness in the non-metal mining industry;

Powder grinding of steel slag, blast furnace slag, power plant slag and fly ash in special steelworks;

High yield and fine grinding of quartz and pyrophyllite powder in glass fiber industry;

Large output powder production of various chemical raw materials in special chemical industry;

Industrial preparation of high yield powders for various materials in more than 100 other industries.

At the same time, there is a good development prospect in the pre-grinding of fine slag powder and cement clinker.

- Country: China (Mainland)

- Founded Year: 1973

- Address: No.1 Guikuang Road, Lingchuan County, Guilin City, Guangxi Province,China

- Contact: Ralap Zeng