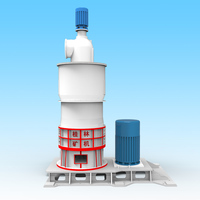

Micro Powder Mill

Specifications

GKWMicro Powder Mill

Micro Powder Mill Technical & Structural Benefits:

Finished particle size 400 mesh -1250 mesh (stepless adjustment);

Breakthrough hard materials and powdery materials, and grind the materials such as talc and fly ash;

Low cost of equipment wearing parts;

Convenient equipment maintenance, maintenance & replacement of wearing parts;

Low energy consumption and high output, for users to create better economic results;

Energy conservation and environmental protection.

Thefine powder grinding machine

The Application Scopes of Micro Powder Mill

Thepowder milling machine is mainly suitable for grinding of conventional materials and the ultra-fine powder processing of non inflammable and non explosive materials, such as kaolin, limestone, calcite, talcum, marble, barite, gypsum, iron oxide red, iron oxide green, aluminum hydroxide, pigment, bentonite, clay, coal, activated carbon and so on, the humidity of which is less than 8%, and the Moh\'s hardness of which is less than level 6.

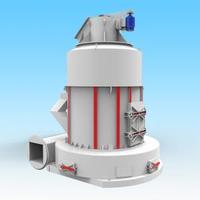

The Structure Characteristics of Micro Powder Mill

The high-pressure micro powder mill mainly consists of the main engine, blower, superfine analyzer, finished cyclone powder collector, bag filter and connecting duct. According to user needs, it can provide with auxiliary equipment such as the hoist, storage bin, electric cabinet, feeder, crusher and so on. In the grinding mill room, the grinding roller assembly is hung on the grinding cradle through the cross arm shaft. The grinding cradle, spindle and the relieving tool post are fixed. The pressure spring is tightly pressed on the outer end of the cantilever housing of the grinding roller bearing chamber by a tension rod. Taking the transverse load axis as the supporting point, the grinding roller is firmly pressed on the inner surface of the grinding ring by the spring pressure.

When the motor is rotated through the drive, the blade of the blade is synchronized with the grinding roller, and the roller rolls around the surface of the grinding ring and rotates around itself. The analysis machine drives the rotating of the impeller through the motor drive. The speed adjustment of the analysis machine determines the fineness of the powder. The relieving tool in the relieving tool post and the grinding roller rotate at the same time. Then the grinding roller rotates on the inner surface of the grinding ring and revolves around itself. The analysis machine drives the impeller of the analysis machine through the motor drive device, and the speed adjustment of the analyzer determines the fineness of the powder.

The Main Features ofGuilin Mining Machinery

The application scope of the high-pressure powder mill is much larger than that of the airflow mill.

Compared with other mills, the grinding pressure of grinding roller on the material can provide 800---1200Kg under the action of high-pressure spring. It saves energy. Under the same circumstance of output and fineness, the energy consumption of the system is only 1/3 of that of the airflow mill.

The investment is small and the efficiency is high. Under the same circumstance of output and fineness, the price is only 1/8 of the airflow mill.

Compared with the air mill, the production link is less. Firstly the airflow mill must crush the material of 20mm to the superfine powder of 100 mesh, and the high-pressure micro powder mill can make the material reached the average particle size about 6.5 μm to 12.5 μm for one time, of which the size is below the 20mm.

The grinding device adopts overlapping type multiple stage seal and has good sealing performance.

The dust removal effect of the mill can totally reach the national dust emission standard.

- Country: China (Mainland)

- Founded Year: 1973

- Address: No.1 Guikuang Road, Lingchuan County, Guilin City, Guangxi Province,China

- Contact: Ralap Zeng