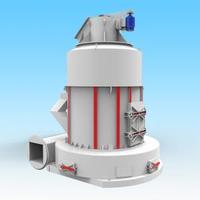

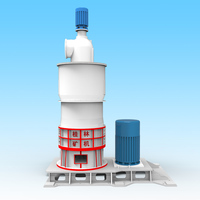

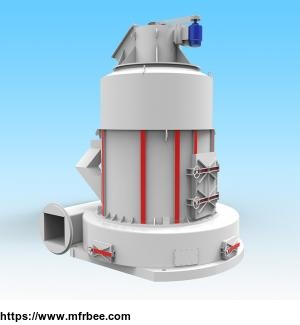

Raymond Mill

Specifications

As national powder R&D center,Guilin Mining Machinery

GKgypsum raymond mill

Application area: used in chemical industry such as grinding glass, rubber, pesticides, enamel, paint, phosphate fertilizer, paper. Hardness below seven Moh\'s hardness following humidity below 6% non-flammable and non-explosive materials.

Suitable material: kaolin, talc, barite, fluorite,calcite, limestone, slag,manganese ore, ash-calcium-powder , wollastonite, feldspar, silica stone, iron ore soil, chrome ore, quartz, gypsum, bentonite,etc.

GUIKUANG grinding machine adopts the advanced structure of similar products at home and abroad, and it has been updated and improved on the basis of Raymond Mill in the same industry. This equipment has higher efficiency, lower power consumption, smaller total area and lower investment for one time than ball mill.

Raymond coal mill is widely used in dolomite, limestone, potash feldspar, barite, calcite, talcum, marble, fluorite, active white soil, activated carbon, bentonite, kaolin, cement, gypsum, glass, etc. These materials\' Moh\'s hardness is no more than 9.3, and the humidity is below 6%. This is a non-flammable and non-explosive mineral process, containing about chemical industry, construction industry and other 280 kinds of materials. The size of the R Raymond mill can be adjusted within 80 to 325 mesh range, and some materials can reach up to 600 mesh.

The Structure of Raymond Mill

The structure of Raymond mill is mainly composed of the main engine, analyzer, fan, cyclone separator, cyclone separator and air duct. The main engine is composed of frame, intake volute, blade, grinding roller, grinding ring and cover.

The grinding roller is tightly pressed on the grinding ring under the action of centrifugal force. Therefore, when the grinding roller and grinding ring wear to a certain thickness, the output, and fineness of the finished product will not be affected. The replacement cycle of grinding roller and grinding ring is long so that the disadvantage of short replacement period of wearing parts of centrifugal grinder can be eliminated. The air flow of the machine is circulating in the fan - mill - whirlwind separator - the fan, so it has less dust than the high-speed centrifugal mill has, the operation workshop is cleaner and the environment is less polluted.

Performance Advantages of the Raymond Mill

1. Convenient transportation and installation

Raymond mill, its ingenious structural design, which makes it occupy smaller space, and makes it more convenient in transportation, installation, operation, and maintenance.

2. High Efficiency and Zero Pollution

The Raymond mill that is produced by our company uses PLC electric automation control to reduce the failure rate and labor cost of the equipment effectively. Meanwhile, it can help to achieve high and efficient production, and achieve a good production environment with zero noise and zero pollution.

3. Fineness can be adjusted arbitrarily

The fineness of the grinding powder of Raymond mill can be adjusted arbitrarily between 80-800 mesh. The applicability is more flexible and extensive. We can see that the GUIKUANG Raymond mill is the best choice for non-metallic ore grinding powder.

4. Long Period Replacement of the Parts

The grinding roller and grinding ring of Raymond mill have a longer replacement period, which eliminates the disadvantages of the short replacement period of the fragile parts of the centrifugal grinder

The Operation principle of Raymond Mill

When Raymond mill works, the material needs to be added to the feeder from the side of the hood.Raymond machine

The Winnowing Selection Process of Raymond Mill

After the materials being grinned, the fan blows the wind into the main engine shell, blowing up the powder, sorting through the analyzer above the grinding room, passing the rough materials into the grinding room and then regrinding it. The suitable fineness materials go into the cyclone collector by the wind. After collection of these materials, the finished products will be discharged through the powder mouth. The air flow from the upper end of the large cyclone collector will return to the fan. The winding road is cyclic and flowing in the negative pressure. The increasing part of the air volume of the cyclic air road is discharged by the exhaust pipe between the fan and the main engine, then this part enters the small cyclone collector to carry out purification treatment.

- Country: China (Mainland)

- Founded Year: 1973

- Address: No.1 Guikuang Road, Lingchuan County, Guilin City, Guangxi Province,China

- Contact: Ralap Zeng