2018 new design fullycontinuous waste plastic pyrolysis plant The advantages of the 2018 new design fullycontinuous waste plastic pyrolysis plant 1) Adapt to external rotation and uniformly heat the reactor 360°. No part of the reactor is heated for a long time, in this way, ...

DoingGroup [Environment] [Environment Projects] [2018-07-06 20:44:37 ]

With the falling prices of crude oil in recent years, it has often been foundthat using new oil sources to produce new plastic products is cheaper than using recycled plastics. This causes many mixed low grade plastics to be sent to incineration or landfill. This approach can ...

DoingGroup [Environment] [Environment Projects] [2018-07-06 20:26:05 ]

The Doingp\'swaste tire pyrolysis plant Doingp designs awaste tire pyrolysis plant The specific safety device mainly includes the following aspects: 1. The reactor adopts a unique three-step welding process. This welding process is not easy to crack and is sufficient to ensure ...

DoingGroup [Environment] [Environment Projects] [2018-05-05 20:10:15 ]

It is believed that many people know that the principle ofpyrolysis of plastics The first step: DoingGroup adopts a vertical condenser, which can generate natural negative pressure. Under natural negative pressure, oil and steam go together to reduce the pressure of the oil ...

DoingGroup [Environment] [Environment Projects] [2018-05-04 18:54:42 ]

Crude oil fractionation The specific workflow ofcrude oil fractionation 1. Heat the reactor and pour crude oil. Steam out of oil and gas, impurities in the crude oil will be distilled out. 2. Distilled oil and gas enter the condensing system and is then liquefied into light oil ...

DoingGroup [Environment] [Environment Projects] [2018-05-04 18:45:50 ]

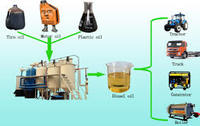

In fact, the plastic fuel conversion process can also be referred to as a plastic pyrolysis process. This process is mainly the use of pyrolysis chemical reactions, the process of crackingwaste plastics into fuel oil First, waste plastics are fed into the reactor via an ...

DoingGroup [Environment] [Environment Projects] [2018-05-04 18:38:14 ]

Automotive has always been a demand in our daily lives, and more and more cars mean creating more and more scrap tires. In this way, how to manage these scrap tires has become a thorny issue. In particular, the disposal of large-scale waste tires is a big problem. You can ...

DoingGroup [Environment] [Environment Projects] [2018-05-04 18:21:20 ]

In order to protect and improve the environment, reduce pollutant emissions, promote the construction of ecological civilization, and respond to the country\'s call forWe want both golden,silver hill and clean water,green mountains as well., according to the latest news, ...

DoingGroup [Environment] [Environment Projects] [2018-04-18 20:03:11 ]

Faced with the accumulation of waste plastics, for many people this is a very vexing thing. However, for DoingGroup, it is a new market worthy of development, and the market has broad prospects. This is because the DoingGroup has the technology to deal with them and turn waste ...

DoingGroup [Environment] [Environment Projects] [2018-04-16 17:18:55 ]

Crude oil is basically the remains of plants and marine life that died millions of years ago. Over time, these fossil remains - hence called \"fossil fuels\" - are buried under the sand and slowly form rocks. Millions of years later, the remains of fossils slowly \"cured\" into ...

DoingGroup [Environment] [Environment Projects] [2018-04-16 17:07:06 ]

Millions of tons of plastic waste pollute our world. If we can turn them into fuel? This is a very worthwhile discussion topic! In the past, this was an impossible goal, but now DoingGroup has developed a waste plastic cracking equipment, which is a closed and oxygen-free ...

DoingGroup [Environment] [Environment Projects] [2018-04-16 16:01:01 ]

Due to its high electrical conductivity and corrosion resistance, it is suitable for motors and wires, pipe devices, heating elements and electronic devices. The global demand for copper is still very large. The data shows that the cost of extracting new copper resources is ...

DoingGroup [Environment] [Environment Projects] [2018-04-16 15:57:37 ]

Due to its high electrical conductivity and corrosion resistance, it is suitable for motors and wires, pipe devices, heating elements and electronic devices. The global demand for copper is still very large. The data shows that the cost of extracting new copper resources is ...

DoingGroup [Environment] [Environment Projects] [2018-04-16 15:53:48 ]

500kg pyrolysis plant in DoingGroup\'s factory A Danish company is committed to the development of waste recycling and renewable energy. As the company expands its scale, it is ready to open up a broader market. After comparing several domestic and foreign waste refinery ...

DoingGroup [Environment] [Environment Projects] [2018-04-12 19:53:25 ]

Crude oil is composed of thousands of compounds with different properties, each of which has a different boiling point. According to the difference in the boiling point, the degree of difficulty in heat evaporation is not the same. The high boiling point is not easily volatile, ...

DoingGroup [Environment] [Environment Projects] [2018-04-12 19:32:00 ]

Tire pyrolysis oil is a new type of renewable energy source extracted from waste tires using tire cracking equipment. Tire pyrolysis oil can be used for fuel oil in all aspects of our daily life. It can also be used to further refine and refine the tire pyrolysis oil to obtain ...

DoingGroup [Environment] [Environment Projects] [2018-04-11 17:19:23 ]

Pyro = heat, split = break up into parts. Pyrolysis is a chemical reaction in which macromolecules are broken down into smaller molecules. Waste plastics and tires are long chain molecules or polymer hydrocarbons. Pyrolysis technology is an industrial process that breaks down ...

DoingGroup [Environment] [Environment Projects] [2018-04-11 16:56:50 ]

Therefining equipment In addition, DoingGroup\'srefining equipment Rapid heating system: The rapid heating system of therefining equipment Diesel purification system: The diesel refined from the standard refining system is brownish yellow. If you want to get better color ...

DoingGroup [Environment] [Environment Projects] [2018-04-11 16:47:47 ]

The high degree of automation and large output of the PLC control system are the two major design highlights of the DoingGroup\'scontinuous pyrolysis device The DoingGroup\'s design does not use a typical rotary kiln but uses a static furnace system with an integrated ...

DoingGroup [Environment] [Environment Projects] [2018-04-10 20:28:43 ]

PLastic pyrolysis plant We all know that fuel, carbon black, combustible gas and other substances can be obtained fromplastic pyrolysis plant In fact, the same carbon black as fuel also has a very high industrial value. Cracked carbon black can be sold directly to the market, ...

DoingGroup [Environment] [Environment Projects] [2018-04-02 20:05:25 ]