Working processing of continuous waste tire pyrolysis plant

Product Quick Detail

- FOB Price

- USD $500,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard wooden cases pacakges

- Delivery

- 15 Days

Specifications

Faced with the accumulation of waste plastics, for many people this is a very vexing thing. However, for DoingGroup, it is a new market worthy of development, and the market has broad prospects. This is because the DoingGroup has the technology to deal with them and turn waste into treasure. Moreover, the annual growth of waste plastics is constantly being refreshed. Therefore, DoingGroup\'scontinuous waste plastic pyrolysis plant

The DoingGroup\'scontinuous waste plastic pyrolysis plant

The main work flow ofcontinuous waste plastic pyrolysis plant

1. Collect waste plastics, this link. You can seek the help of a waste recycling station and establish a cooperative relationship with it.

2. Place the collected plastic into a plastic crusher and crush it.

3. Put the crushed plastic into the reactor and heat the reactor in multiple stages. Can crack a lot of oil and gas.

4. The oil and gas that has been cracked enters the condensing system under the action of high and low pressure, is liquefied into heavy oil, and falls into the oil tank.

5. Degreasing and desulphurization of the obtained heavy oil is the final fuel oil.

6. The carbon black produced during the combustion process is automatically removed at the other end of the equipment.

Through this series of reactions, we can finally get fuel, carbon black. Their specific uses are as follows:

Fuel oil usage

1. Fuel oil: Mainly used in steel plants, boiler heating, heavy oil generators, and cement plants.

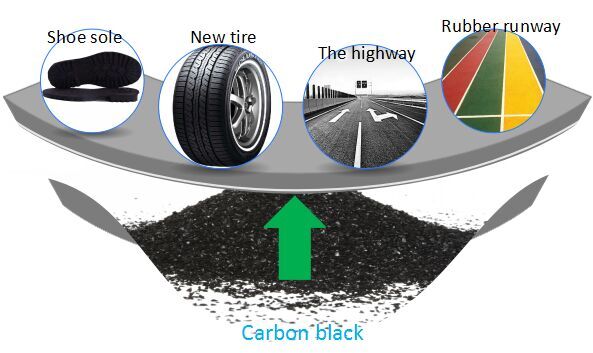

Carbon black usage

2. Carbon black: Mainly used for pressure ball combustion, or refined milling. Refined flour can be used for new tires, rubber soles, and pigments.

Continuous plastic pyrolysis plant cases

The DoingGroup\'scontinuous waste plastics pyrolysis plant

1. 24 hours continuous work, continuous slag discharge, continuous feeding, save time and effort.

2. Using PLC control system, a high degree of automation, saving labor costs.

3. Indirect heating mode, long service life.

4. Accurate calculation system to ensure full cracking and high oil yield.

DoingGroup provides door-to-door installation and technical guidance services. Please feel free to contact us with any equipment problems! !

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email:oilmachine@doinggroup.com

http://www.doinggroup.com

http://www.china-doing.com

http://www.wastetireoil.com

http://www.continuouspyrolysisplant.com

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: European Union

- Founded Year: 1987

- Address: Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Province, China

- Contact: Boinne Zhao