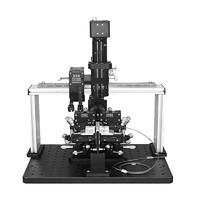

5W Ultra High Power Deep UV Curing Spot Light/Lamp/System

Product Quick Detail

- FOB Price

- USD $300.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- china(mainland)

- Packaging

- 1 set each carton

- Delivery

- 3 Days

Specifications

For applications such as bonding, potting or fluorescence excitation, the wavelengths 365, 385, 395 and 405 nm are available. With the variety of wavelengths, you remain particularly flexible and can upgrade and change over at any time. With several UV LED lamps, the irradiation can also be ideally homogenized to achieve the best possible uniformity.

Advantages

The UVLED area light source produced and developed by Futanxi Electronic Technology has the advantages of:

• highly efficient operation (high output)

• initial start

• lower heat input

• longservice life; average use time is more than 20000h

• the number of UVLED surface light source irradiation heads (1-4 & 1-8) can be selected according to the needs of use.

• The UVLED surface light source adopts touch screen control mode, the power is adjustable (10%-100%), and the irradiation can be set freely;

• small in size, occupies less area, easy to install, and can be used with the assembly line workshop.

Applications

• Hard disk assembly (Read-write head packaging, gold wire fixation, bearing, coil, chip bonding, etc.)

•Assembly of motors and components (Wire, coil fixed, coil end fixed, PTC/NTC components bonding, protect transformer core)

•DVD/Digital Camera (Lens, lens pasting, circuit board reinforcement)

•Sensor production (Gas sensor, photoelectric sensor, optical fiber sensor, photoelectric encoder, etc.)

•Assembly of cell phone components (Camera lens, receiver, microphone, shell, liquid crystal module, touch screen coating, etc.)

•TFT-LCD pasting and packaging of LCD panel FPC

•UV LED light curing application of PCB

•UV LED light curing application of Optics Series

•Optical element assembly (Lens group, prism, DLP optical engine assembly, CCD, COMS)

•Optical communication industry components (All kinds of glass packaging structures are bonded or sealed, the fixation of tiny components, etc.. Such as PLC Branching Unit, WDM, AWG, etc.)

•UV LED light curing application of Research Institutes

•Medical device and medical accessories LED UV light source curing application

•Capacitive touch screen adhered to curing

•UV encapsulation and curing application of laser

- Contact: Lyna Sia