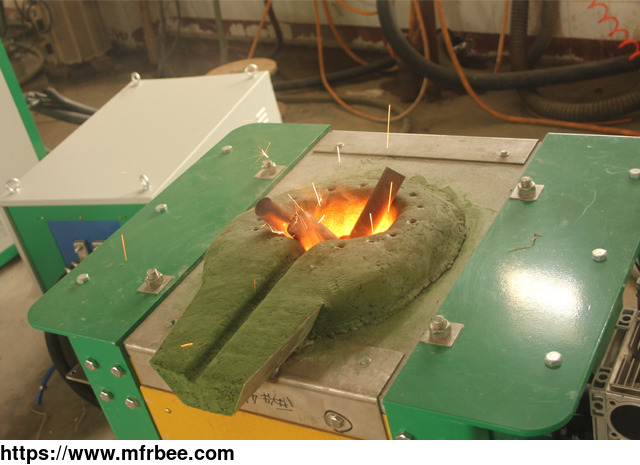

Steel Melting

Specifications

The process of steel smelting to finishing are all completed in a high-temperature heating environment. The induction melting of iron, the composition of ingredients, and roll forming are all accompanied by heating. The process of recycling, smelting and purifying waste steel is also accompanied by heating. Thus, induction heating actually plays an irreplaceable role in the process of ferrous metal smelting. The traces of industrial induction melting machine can be seen from large blast furnaces to small smelting furnaces. As a professional induction heating machine manufacturer, JKZ focuses on the small smelting furnace, with the capacity ranging from 15KG to 500KG so as to meet the needs of small and medium-sized customers for steel smelting. Adopting IGBT inverters, our industrial induction melting machine is well featured with the characteristics of low failure rate, long use life, advanced module design and easy maintenance. They also use 30% less electricity than the traditional furnaces. In a word, JKZ\'s power supply and the dedicated RH melting furnace body can effectively form a complete set of smelting special system to help their users to quickly and easily complete the smelting work.

Benefits of Induction Steel Melting

As smelters seek newer and more cost-effective steel making methods, the design and operation of induction melting furnaces continue to improve.

The following are five advantages of induction melting over traditional open hearth furnaces.

1. Improve efficiency

The melting point of steel is approximately 1300°C (2500°F). The efficiency of induction melting is closely related to its power requirements. The high-voltage primary coil in the induction furnace generates a frequency of approximately 50 Hz to 10,000 Hz per second. This allows rapid heating of the melting, thereby providing higher thermal efficiency. The increased efficiency in the induction melting process leads to higher production and less combustion losses. Adding materials can reduce the melting time of the metal, thereby increasing the output of steel.

2. Reduce operating costs

The financial impact of running induction melting and forging is closely related to energy efficiency. Most industries that produce smelting furnaces are constantly innovating and improving new steel making technologies. The stove adopts the latest technology to reduce power consumption, thereby saving production costs. In addition, the automation of the process reduces waste products such as metal losses that are common in electric furnaces.

3. Improve metallurgical functions

The induction melting furnace working principle revolves around using a high-voltage primary coil to generate electromagnetic current to heat the metal. Since the electric charge causes the molten steel in the center to rise, the inductor and molten steel usually repel each other. This phenomenon is commonly referred to as electromagnetic stirring. The electromagnetic stirring of molten steel leads to the uniformity of the chemical composition of the metal product.

4. Reduce oxidation loss

The core induction furnace reduces the oxidation burning loss of the elements in the steel. The low frequency associated with induction heating coils reduces the burning speed of metallic elements, thereby minimizing the oxidation of molten steel. In addition, no electrodes are used in the smelting process, thereby reducing the generation of slag. Therefore, the waste generated by the furnace is reduced, and there is no need to worry about adding carbon to the electrode.

5. Cleaner operation

Compared with electric furnaces, induction fusion casting has less negative impact on the environment. This process records the reduction in gas, smoke, and dust emissions associated with other types of castings and forgings. Induction metal furnaces are cleaner and can better control emissions and their release to the environment. You can focus more on the casting process and reduce the waste generated. In addition, compared with the open hearth furnace, the forging furnace is less noisy.

JKZ is a professional induction heater factory, we provide induction heating machine china, melting machine for steel, induction melting steel, etc. Contact us to buy induction heating products.

- Country: China (Mainland)

- Founded Year: 1993

- Address: NO.688th South baoguang Road, Xindu District,Chengdu,Sichuan ,China

- Contact: cn jkz