Evaporator System

Specifications

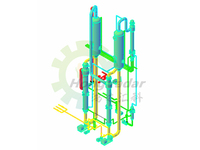

Multi-effect TMR Evaporator System

HVD-EV-T series TVR vapour recompression evaporator is a kind of compressor evaporator condenser system. The multiple effect evaporator working principle is using secondary steam many times according to the theory of vacuum low-temperature evaporation to save steam energy. According to the evaporation capacity and energy-saving requirements, it can be divided into single effects, two effects, three effects, four effects, five effects, and so on. The structure is divided into falling film, forced falling film, forced circulation, and so on.

Multiple effect evaporators are used to evaporate heat-sensitive, high concentration, high viscosity, and corrosive materials, and suitable for concentration of corn steeping liquid and maltose syrup in starch & glucose industry, fruit juice and flavored semen in the food industry, liquid milk in the dairy industry, sugar juice in the sugar industry and distiller\'s grains filtrate in the alcohol industry. As one of the reliable evaporation equipment manufacturers, we make different types of multiple effect evaporator for sale, such as single effect evaporator and forward feed multiple effect evaporator with the best evaporation machine price.

Main feature of Multi-effect TMR Evaporator System

The whole compressor evaporator condenser system is designed reasonably and beautifully, running stably, highly efficient and energy-saving, and low steam consumption.

High concentration ratio, falling film evaporation, so that the viscosity of the material liquid easy to evaporation, and short time concentration.

Special design, realize switching efficiency through simple operation to adapt to the production of different products.

Low evaporation temp, suitable for the concentration of heat-sensitive materials.

High heat transfer coefficient and high evaporation rate, which can prevent the \"drywall\" phenomenon.

High separation effect and greater flexible operation.

Compact structure, small floor area, and simple & smooth layout.

In and out of the material continuously. The material liquid can reach the required concentration after passing through the equipment once.

If the material needs continuous sterilization treatment, the sterilization, and concentration of two processes can be completed at one time.

Equipped with CIP cleaning pipeline. The calandria type evaporator can be cleaned on the spot. The whole equipment is easy to operate without dead Angle.

The power control is realized by the control cabinet, and the automatic control system can be installed according to the user\'s requirements.

Special pump, reliable seal, stable performance, little maintenance, and smooth operation.

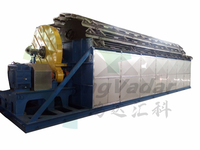

MVR Evaporator System

HVD-EV-M series MVR compressor evaporator condenser system compresses the secondary steam generated by the steam according to the principle of mechanical compression, so as to raise its temperature to a certain extent and return the heating system to replace the raw steam as the heat source of the heater, so as to make full use of the waste stream, recover the latent heat, improve the thermal efficiency, and achieve the purpose of saving steam energy. At the same time, mechanical vapour recompression evaporator also reduces the demand for external cooling resources, reduces energy consumption, and reduces pollution. This product of mvr evaporator design and technology is mainly used in multi-effect evaporation and crystallization equipment.

Evaporator System Technical Parameters

Multi-effect TMR Evaporator System Technical Parameters

Model Evaporation capacity

kg/h Steam consumption

kg/h Each effect vacuum, mmHg Each effect temp. ℃ Steam pres.

MPa Feed DS,% Discharge DS, %

1st effect 2nd effect 3rd effect 1st effect 2nd effect 3rd effect

HVD-EV1.0-T 1000.0 250-300 0.0 448.0 640.0 99.0 76.0 53.0 0.6-1.0 6-7

(corn steeping liquid) 42-48

(corn steeping liquid)

HVD-EV3.0-T 3000.0 750-900

HVD-EV4.5-T 4500.0 1200-1350

HVD-EV6.0-T 6000.0 1600-1800

HVD-EV9.0-T 9000.0 1500-2700

HVD-EV12.0-T 12000.0 3000-3600

HVD-EV15.0-T 15000.0 3750-4500

HVD-EV20.0-T 20000.0 5000-6000

HVD-EV25.0-T 25000.0 6250-7500

HVD-EV30.0-T 30000.0 7500-9000

HVD-EV50.0-T 50000.0 12500-15000

Comparison and Evaluation Table of MVR and Five-effect Evaporator

Evaporation type Five-effect evaporator MVR evaporator

Evaporation capacity × evaporator qty. 100tph×1set 100tph×1set

Energy consumption Steam, t/h 27.4 5.56

Pump electricity consumption, KWH 465 430

MVR electricity consumption, KWH 0 1890

Cooling water consumption, m3/h 1300 300

Annual energy consumption Steam price, RMB/ton 180

Electricity price, RMB / KWH 0.55

Running days, days / year 330

Annual steam consumption cost around, ten thousand RMB / year 3900 790

Annual power consumption cost around, ten thousand RMB / year 200 1000

Annual energy consumption around, ten thousand RMB / year 4100 1800

Main material 304/316L

The payback period for the investment of fixed assets that are overinvested due to the use of MVR evaporator Around 230 days

Beijing Hongvadar Engineering Technology Co. Is a professional starch processing plant, we provide single cyclone separator, vapor recompression evaporator, mechanical recompression evaporator, single effect evaporator and multiple effect evaporator, multiple effect evaporator flow diagram and etc. Want to know more, contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2020

- Address: Bldg.202-1207, No.19 Huanjing Road, Tongzhou District, Beijing

- Contact: HongVadar com