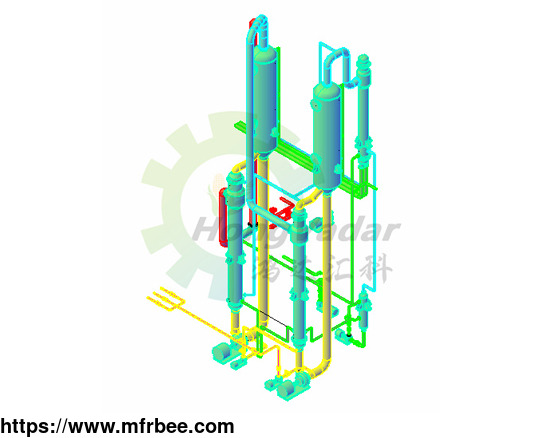

Continuous Evaporative Crystallization System

Specifications

HVD-CC-T series continuous crystallization equipment system is designed and developed by our factory with patent applied.

Core Of Evaporative Crystallization Process Control

Design enough long crystal time according to crystal characteristics to create an environment conducive to the growth of crystal structure.

Continuous cooling crystallizer adjusts the direction of materials, control the number of microcrystals, realize the whole process control of seed generation, seed growth, elimination of microcrystals, growth of qualified particles, and timely discharge of qualified particles.

Most businesses take crystallization as the process of concentration. It is believed that the concentration reaches supersaturation, the crystal forms naturally, and there is no awareness and measures to control the crystal quality. The control of the crystal purpose is ignored, and the influence of crystallization on separation and drying is not fully considered, which makes the subsequent section treatment more difficult due to the crystallization. Therefore, the purpose of crystallization is to improve the overall yield and product quality and reduce the product production cost by continuous crystallization equipment.

Characteristics Of Evaporative Crystallization System

Crystallisation and evaporation system is used for products with general requirements on crystal shape and size and can achieve high concentration discharging.

According to the characteristics of materials and the evaporation capacity, Crystallisation and evaporation system can be designed as a single-effect or multi-effect evaporative crystallization system.

The unique design of the crystallizer can meet the intermittent crystallization, semi-continuous crystallization, and continuous crystallization system. Continuous crystallization equipment can meet the continuous feed, continuous discharge process requirements.

The whole crystallisation and evaporation process system evaporates under the vacuum condition, with relatively low temp, fast evaporation speed, high evaporation concentration, and the relatively high viscosity of the liquid material is not easy to scale or block, which can achieve the maximum crystal ratio under the same energy consumption.

HongVadar relies on professional design, strict production management, the fine processing procedure, provides high efficiency and energy saving continuous crystallization equipment system for the customer. The manufacturing factory has passed the international ISO9001 quality system certification, and with the design and manufacturing capacity of pressure vessels. Customers can choose Chinese GB, International ISO, American standard ASME, European standard PED and other standards for equipment design and production according to their needs.

Continuous Evaporative Crystallization System Technical Parameter

Model Ev capacity

kg/h Steam consumption

kg/h Each effect vacuum, mmHg Each effect temp. ℃ Steam pres.

MPa Feed DS,% Discharge DS, %

1st effect 2nd effect 3rd effect 1st effect 2nd effect 3rd effect

HVD-CC1.0-T 1000.0 330-400 300 510 750 85 76.0 55 0.5-0.6 5-6

(MSG) 55-65

(MSG)

HVD-CC3.0-T 3000.0 990-1200

HVD-CC4.5-T 4500.0 1485-1800

HVD-CC6.0-T 6000.0 1980-2400

HVD-CC9.0-T 9000.0 2970-3600

HVD-CC12.0-T 12000.0 3960-4800

HVD-CC15.0-T 15000.0 4950-6000

HVD-CC20.0-T 20000.0 6600-8000

Beijing Hongvadar Engineering Technology Co. Is a professional hydrocyclone manufacturers, we provide small scale tomato processing plant, continuous oscillatory baffled crystallizer, circulating liquid evaporator crystallizer, evaporation vs crystallization, continuous crystallisation and etc. For more info about how is crystallization different from evaporation, contact us.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 2020

- Address: Bldg.202-1207, No.19 Huanjing Road, Tongzhou District, Beijing

- Contact: HongVadar com