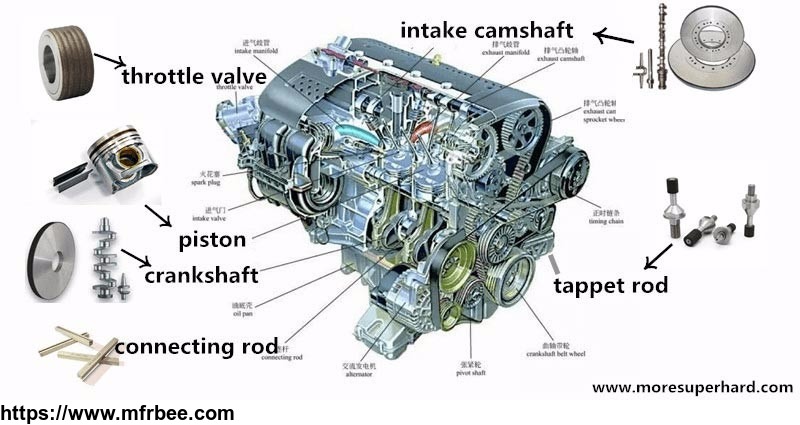

Application of PCD tool in automobile manufacturing

Specifications

Application of PCD tool in automobile manufacturing

Dry cutting

Due to their sensitivity to environmental influences, automotive parts are increasingly using dry cutting or using minimal amounts of coolant during processing. Driven by the cost of cooling (including the associated waste recycling costs), cutting speeds are also increasing, which is not possible with conventional carbide tools.

When dry cutting with a conventional tool or tool material, the surface roughness of the workpiece to be machined is poor due to the change in the geometry of the cutting edge of the tool and the increase in heat caused by friction in the cutting zone.

Higher machine speed

Last but not least, the development of machine tool technology has resulted in ever-increasing spindle speeds and feed rates for faster machining. Only a few years ago, the spindle speed of the machine tool was only 6000r/min, but now it has reached 30,000-40000r/min, and the acceleration of the shaft can reach 2G. With the support of powerful computer capabilities, this machine can perform the motion functions required for machining (such as helical interpolation movement in thread milling). In order to convert this speed advantage into a machining advantage at the point of action, the corresponding tool material is required. However, with carbide tools, the cutting speed can only reach 400m/min; while tools with polycrystalline diamond (PCD) cutting edges can cut at speeds up to 3000m/min (depending on the cutting process). In addition to higher processing speeds, the main advantages of PCD tools include longer tool life and, in many cases, better surface finish quality.

A wide range of products The JEL Precision Tool Company, part of the German Komet Group, offers a wide range of PCD tooling products, including the highly efficient PCD drills DRILLCUT and DRILLMAX with carbide inserts. Both drills are capable of drilling holes up to 5D deep. The DRILLCUT is a straight groove drill with 2 cutting edges and 4 guide ribs and a coolant channel for internal cooling. DRILLMAX also uses the same internal cooling design, but it is a spiral groove drill with two guiding ribs. The DRILLMAX drill bit is precisely positioned, drilling accuracy is up to IT8-IT9, and it achieves long tool life and good surface finish. The company\'s product line also includes PCD grooving tools. During machining, the PCD cutting edge of the tool is drilled from the top of the workpiece along the center hole and then tangentially offset from the center. The maximum depth of cut can be twice the diameter of the tool. These tools can also be used for proper milling and for machining circular geometries for good surface finish and burr-free cutting edges. The standard 2-blade PCD grooving tool has a minimum diameter of 6mm and the 3-blade tool has a diameter of 16-20mm.

High reliability thread milling

JEL is one of the few technical authorities in the industry in the field of complex internal threading, especially when it comes to thread milling or the development of specialized solutions for specific machining. The famous MGF and TOMILL thread milling cutters are the most commonly used machining tools. The MGF thread milling cutter with PCD tip has a countersunk hole in the shank. The body is made of hard alloy, which is especially suitable for processing aluminum alloys and other materials that are usually processed by PCD. The tool can mill the standard thread size of the M6-M12 with a cutting edge length twice the nominal diameter. Similarly, TOMILL (GWF) thread milling cutters with tool diameters of 16 mm and 20 mm can be machined with threads ≥ 20 mm in diameter. In addition, JEL offers process-oriented solutions that include as many machining operations as possible. Drills and thread milling cutters (BGF) with PCD tips have also been introduced. In addition to machining tapped holes, 90° chamfers and threads, the tool can also be used to cut protective holes in one machining operation. .

If you need any products, do not hesitate to contact

Annamoresupe@gmail.com

Anna.wang@moresuperhard.com

WhatsApp:+8615617785923

Skype:Annawng

Wechat:15617785923

QQ:1664333593

Mobile:+86-156177854923

Tel/Fax:+86-0371-86545906

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Africa,Americas,European Union

- Founded Year: 2010

- Address: No.171 Zhongyuan Rd, Zhongyuan District, Zhengzhou, Henan,450001 China

- Contact: Anna wang