Qingdao Hilong Machinery Co., Ltd Manufacturer

Company Introduction

HILONG INDUSTRIAL GROUP CO.,LTD is a professional and experiential industrial group company which mainly produce the Ringlock Scaffolding, Kwikstage Scaffolding, Formwork and Accessories, OEM Casting & Forging Products in china. Our head office locate in Qingdao city which is 20KM away from Qingdao Seaport and 10KM away from Qingdao International Airport. And our subsidiary company include Qingdao Hilong Industrial Co.,Ltd, Yongnian Hilong Scaffolding Co.,Ltd and Weifang Hilong Casting Co.,Ltd.

Our group total factory space have more than 35000 square meters,including Yongnian Hilong Scaffolding Co.,Ltd with 27000 square meter, and Weifang Hilong Casting Co.,Ltd with 8000 square meter. Our employee have more than 350 staffs. The average annual turnover is 20 Million US dollars. As one of the biggest manufacturer in our region, we insist on the “Best Quality with Best Price”. One side we produce the high quality products and supply the best service, another side we offer the competitive price to customer through improving our mechanical automation and intellectualized level to increase our productive efficiency.

We have got the Products Certification of SGS, the Factory Auditing certification of BV and SGS, the ISO 9001:2008 Quality Management Certification, and our products also meet the CE and DIN standard, the AS/NZS 1576 and AS 3610 standard, and also the EN 74 standard.

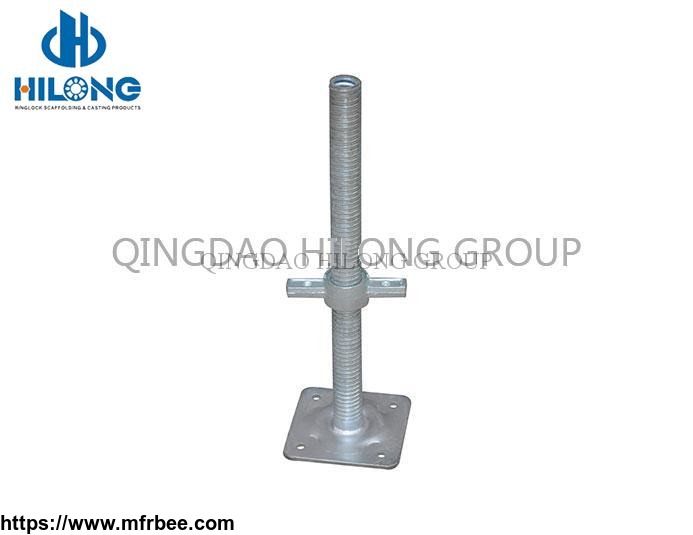

Our main products include Ringlock Scaffolding System, Ringlock Scaffolding Accessories (Rossete, Ledger End & Brace End), Kwikstage Scaffolding System, Shoring Prop, Fork Head and Tripod, Push Pull Support, Australia Frame and H frame, Scaffolding Coupler, Adjustable Screw Jack, Top Cup, Blade, Formwork Wing Nut, Formwork Clamp, Swivel Nut, Tie Rod, Water Stop, Prop Nut, Rapid Clamp, Wooden H Beam, Formwork Beam Support, Formwork Frame Corner, Welding Bolt and so on.

As a leader manufacturer in construction field, we equip with many Automatic and Advanced machines and production lines which can improve our productive efficiency much more. They have the Ringlock Scaffolding Auto-welding lines, Screw Jack Auto-welding lines, Shoring Prop Auto-welding lines, CNC cutting lines, Automatic tube cutting lines, Cold rolled machines, Punching machine with 60Tons, 80Tons, 100Tons, 160Tons and 200Tons, Drop forged friction pressed machines, CNC lathes, Multi-drilling machines, Semi-auto painting and dipping line, High-power Electronic Furnaces, Automatic Shell Casting lines, Sand moulding lines, The digital control Head Treatment machines, and other advanced accessory equipments.

Meanwhile we also have the completed and professional quality control equipments, including the Digital-Display Multi-function Tensile Strength Testing Machine which can test the tensile strength of Wing nuts and all nuts with thread, Formwork Clamp, Tie Rod, Coupler, Water stop and the pressure capacity of Base jack, Head jack and other screw and tubes. And also equipping with the Multi-function Pressure Machine which can test the Loading Capacity of Scaffolding Standard(Vertical) and Shoring Prop, Shoring Frame Vertical, Tube Material and so on. In addition, we also have the very important and useful quality equipments for casting, involve the Spectrometer Machine which test and control the chemical composition, Metallographic Test Machine, Hardness Test Machine and so on. And we also use the Thickness gauge to test the galvanized thickness, use the Position gauge to test the special position and so on.

HILONG, welcome you from all over the world to visit us. Maybe contacting us can become a big chance for both side.

Contact information:

Email:sales@hilongmetal.com

Tel:0086-0532-86660316

Mobile:86-15166669902

Web:www.hilongmetal.com