Product Name Custom Manufacturing CNC Machining Products Materials Aluminum AL 6061, 2024, 7075 etc. Steel CPV-10V, 17-4PH etc. Stainless Steel 440C, S136H, SUS304, XW-41 etc. Brass C2800 Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, etc. Other Special Precision Processi

Dongguan Richen Precision Manufacture Co.,Ltd [2022-11-15 15:42:30 ]

Prototype mould are rapid processing for the molds. It\'s totally different from production molds as they can\'t be used in the long term. As a professional mold maker for over 15 years, Packson mold can handle all kinds of mold including prototypes. We bring not only high skille

Packson Mold Co., Ltd [2022-10-30 17:04:02 ]

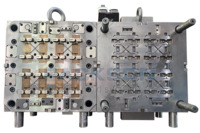

Multi cavity mould is an injection mold that has more than one cavity. The shape of each cavity is the same. Multi cavity mold design is to produce multiples of the same part for high volume production since it means each production will produce a large number of finished parts.

Packson Mold Co., Ltd [2022-10-30 17:01:05 ]

Packson is not totally the same as other medical plastic injection molding companies. Because we are an ISO-certified medical injection molding provider. Packson had got the certification of ISO 13485 2018 and ISO 9001 2008. We\'ve been working with healthcare and medical plastic

Packson Mold Co., Ltd [2022-10-30 16:59:36 ]

Product Description Product Name Custom Manufacturing CNC Machining Products Materials Aluminum AL 6061, 2024, 7075 etc. Steel CPV-10V, 17-4PH etc. Stainless Steel 440C, S136H, SUS304, XW-41 etc. Brass C2800 Copper, bronze, Magnesium alloy, Delrin, POM, Acrylic, etc. Other Specia

Dongguan Richen Precision Manufacture Co., Ltd. [2022-09-16 16:51:34 ]

Home appliance mould combines different types of molds such as gold stamping mould, plastic mould, and adsorption mould together. Therefore, household appliances are closely related to home appliance mold. As a leading home appliance plastic injection moulding manufacturer, GM-TE

Glitter Mold Technology Co., Ltd [2022-09-16 09:08:33 ]

With the fast growth in the electronic industry, the demand for injection molding electronics is much higher. The injection molding electronics can be intricate or simple. Intricate injection molding electronics can be economical because they combine many parts into one piece whi

Glitter Mold Technology Co., Ltd [2022-09-16 09:07:53 ]

Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The electronics plastic injection mold has been widely applied to various industries. As a result, electronics injection mold manufacturers have been ta

Glitter Mold Technology Co., Ltd [2022-09-16 09:07:25 ]

Gmmoldtech CNC component can greatly reduces the number of tooling, and complex tooling is not needed to process complex parts. If we want to change the shape and size of the parts, we only need to modify the processing program of the parts, which is suitable for the plastic mold

Glitter Mold Technology Co., Ltd [2022-09-16 09:05:50 ]

As the foundation of the automotive industry, injection molding automotive parts are necessary factors to support the sustainable and healthy development of automotive mold manufacturers. In particular, the current independent development and innovation in the automotive parts mo

Glitter Mold Technology Co., Ltd [2022-09-16 09:05:21 ]

2k injection molding is a manufacturing process that refers to molding two materials or colors into one plastic part. This technology combines two materials or two colors into one ending plastic part by using a 2K automotive plastic injection moulding machine. The selection of th

Glitter Mold Technology Co., Ltd [2022-09-16 09:04:49 ]

Two Shot Tool Construction Part two shot tool construction saves the injection machine quantity and plant area, lower the labor cost and minimize the part handling, although mould cost is high but later process cost is lower, not on... Two Shot Plastic Injection Molding Parts How

HANKING MOULD ENGINEERING LTD. [2022-08-16 11:40:40 ]

Sewing Machine Frame Mould Large plastic frame plastic injection sewing molds, suited for oversize embroidery projects. Mould Name Embroidery Machine Frame Mould Part Material Pa 66 GF50% Product Description Large Embroidery hoop inner frame Mould Cavity 1 Cavity Mould Size 400*6

HANKING MOULD ENGINEERING LTD. [2022-08-16 11:39:26 ]

Injection Plastic Mold Injection plastic mold is another name for plastic injection mold. This is just how people in various places call injection molds differently. The injection plastic mold can be made as single cavity plastic mold or multi cavities injection mold according to

HANKING MOULD ENGINEERING LTD. [2022-08-16 11:37:31 ]

Mould Name Precision Automotive Plastics Mould Part Material PA66 G30 Product Description BODY plastic Mould Cavity Cavities Mold Mould Cavity Steel 2344ESR Mould Injection System hot runner Mould Ejection System ejector pin Mould Cycle Time 26\'s Mould Life Cycle 1,000,000 Lead

HANKING MOULD ENGINEERING LTD. [2022-08-16 11:36:28 ]

Mould Type Plastic Precision Car Parts Mould Production Material PC, PP, PA6, PA66, PE, ABS, HDPE, TPE, TPU, PET, PPS, POM, PBT, PMMA, PPS, SAN, etc. No of Cavities Single or Multi cavity Core Material 2344, S136,H13,S7, NAK80,SS420, P20 and other steel according to customer moul

HANKING MOULD ENGINEERING LTD. [2022-08-16 11:35:25 ]

PA66 GF30 Car Parts Plastic Injection Mold If you want to get the product is straight, your mold design and mold processing are also made straight, but there will be a bent product, deformed or the product size is out tolerance, they were caused by material, temperature, shrinkag

Unique Solutions Mold [2022-08-15 14:51:05 ]

The same type of material of different colors is usually used for two-color injection overmolding(or 2k injection molding)so that the bonding strength of the first color and the second color plastic is the best, but due to the functional requirements of the product, the perfo

Unique Solutions Mold [2022-08-15 14:50:08 ]

The runner filling balance must be considered when designing the multi cavity plastic mold in order to ensure the best effect of filling balance, the multi cavity mold will be multiple of 4 to design the mold generally, such as 4. 8. 16. 32. 64. 128 points, etc. ; Most of the mul

Unique Solutions Mold [2022-08-15 14:49:00 ]

Metal Insert Molding Choosing suitable material and molding conditions, not only for products that are easily deformed and damaged (such as glass, coils, electrical parts, etc.), can also be sealed and fixed by material. Choosing a suitable mold structure, the insert product can

Unique Solutions Mold [2022-08-15 14:46:03 ]