Car lights are mainly used for lighting, which can be said to be the eyes of cars. Car lights are the collective name for all car lighting systems. The appearance of automobile lights has high requirements, and several important parts are transparent parts and electroplated parts

Green Vitality Industry Co., Limited [2023-01-09 11:03:58 ]

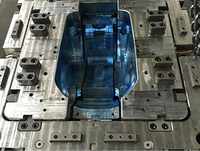

With the vigorous development of the automotive industry, plastic auto part mold is also developing rapidly. 90% of auto parts are produced by injection molds, which is a huge market opportunity for auto plastic parts manufacturers . Common large-size auto parts such as car bumpe

Green Vitality Industry Co., Limited [2023-01-09 11:03:42 ]

The front and rear bumpers of the car are made of plastic, which not only maintains the protection function, but also has the characteristics of harmony and unity with the body shape, lightweight, and low fuel consumption. The plastic front bumper consists of three parts, namely

Green Vitality Industry Co., Limited [2023-01-09 11:03:03 ]

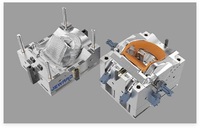

Green Vitality Industry is a full-service mold manufacturer specializing in plastic injection mold design & engineering support, injection mold manufacturing, and qualifying of plastic injection molds. Green Vitality operates plastic injection molding machines ranging from 80T to

Green Vitality Industry Co., Limited [2023-01-09 11:02:26 ]

Home appliance mold combines different types of molds such as gold stamping mould, plastic mould, and adsorption mould together. Therefore, household appliances are closely related to china home appliance mold . As a leading home appliance china plastic injection molding company,

Glitter Mold Technology Co., Ltd [2023-01-06 09:50:19 ]

With the fast growth in the electronic industry, the demand for injection molding electronics is much higher. The injection molding electronics can be intricate or simple. Intricate injection molding electronics can be economical because they combine many parts into one piece whi

Glitter Mold Technology Co., Ltd [2023-01-06 09:50:00 ]

Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The in mould electronics has been widely applied to various industries. As a result, electronics injection mold manufacturers have been talking about ra

Glitter Mold Technology Co., Ltd [2023-01-06 09:49:44 ]

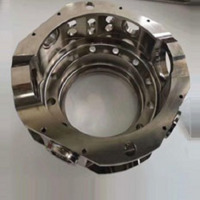

Gmmoldtech CNC component can greatly reduces the number of tooling, and complex tooling is not needed to process complex parts. If we want to change the shape and size of the parts, we only need to modify the processing program of the parts, which is suitable for the plastic mold

Glitter Mold Technology Co., Ltd [2023-01-06 09:49:08 ]

As the foundation of the automotive industry, injection molding automotive parts are necessary factors to support the sustainable and healthy development of automotive mold manufacturers. In particular, the current independent development and innovation in the automotive parts mo

Glitter Mold Technology Co., Ltd [2023-01-06 09:48:47 ]

2k injection moulding is a manufacturing process that refers to molding two materials or colors into one plastic part. This technology combines two materials or two colors into one ending plastic part by using a 2K automotive plastic injection moulding machine. The selection of t

Glitter Mold Technology Co., Ltd [2023-01-06 09:48:29 ]

MIM China is a repeatable process for complex components made from high-temperature alloys. MIM parts are near fully dense, which provides excellent mechanical, magnetic, corrosion, and hermetic sealing properties, and allows secondary operations like plating, heat treating, and

KUNSHAN JINLONGYUAN NEW MATERIAL TECHNOLOGY CO.LTD [2023-01-06 09:28:12 ]

Application of Rapid Prototyping in Aerospace Industry Xin Pin is an ISO9001 certificated manufacturer that we can be trusted to handle the aerospace & UAV industries. With our experience, we have a good command of each step of production to undertake your aerospace project produ

Xin Pin Prototype Manufacturing Co.,LTD [2022-12-26 13:57:47 ]

240L GARBAGE BIN MOULD JF32-1 DETAILS Product Description 240L Garbage bin mould Item No. JF32-1 Product Material PP Product Size 720*585*1020mm/680*535*70mm Product Weight 8350g+1034g Total Mould Quantity 2 Moulds Max. Injection Machine Required 2400T Jeward Mould is confident w

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-12-26 11:42:48 ]

20L PAINT BUCKET MOULD DETAILS Product Description 20L paint pail mould Item No. JH45-2 Product Material PP` Product Size 325*325*370 Product Weight 950 Total Mould Quantity 3 Max. Injection Machine Required 470T Injection Machine 470T/250T As a professional drawer mould factory,

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-12-26 11:42:22 ]

20 BOTTLE BEVERAGE/BEER CRATE MOULD DETAILS Product Description 20 Bottle Crate Mould Item No. JJ78-1 Product Material HDPE Product Size 440*295*270 Product Weight 1662 Total Mould Quantity 1 Max. Injection Machine Required 800T Injection Machine 800T Jewards Mould is confident w

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-12-26 11:41:53 ]

120L GARBAGE BIN MOULD DETAILS Product Description 120L Wheeled Garbage Bin Item No. JG04-1 Product Material PP Product Size 550x490x840mm Product Weight 7000g Total Mould Quantity 4 sets Max. Injection Machine Required 1200T Injection Machine 1600T RELATED WASTE BIN MOULD 6L/12L

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-12-26 11:41:25 ]

Among the three key elements of injection molding industry, material, machine and mould, the plastic injection mould is the most important and changeable one. It brings countless changes to plastic products. And because of the variety of products, processes and materials, the mou

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-12-26 11:40:44 ]

The same type of material of different colors is usually used for two-color injection molding(or 2k molding)so that the bonding strength of the first color and the second color plastic is the best, but due to the functional requirements of the product, the performance differe

Unique Solutions Mold [2022-12-15 14:31:58 ]

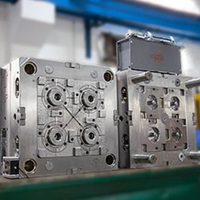

Multi Cavity Mold Design The runner filling balance must be considered when designing the multi-cavity mold in order to ensure the best effect of filling balance, the multi cavity tool will be multiple of 4 to design the mold generally, such as 4. 8. 16. 32. 64. 128 points, etc.

Unique Solutions Mold [2022-12-15 14:31:31 ]

For medical plastic components manufacturer, it means that medical supervisors are required to supervise and manage the materials used to manufacture the equipment, the medical injection molds parts are designed to withstand high temperatures and chemical corrosion. In this way,

Unique Solutions Mold [2022-12-15 14:30:52 ]