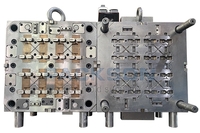

Mould Type Plastic Precision Car Parts Mould Production Material PC, PP, PA6, PA66, PE, ABS, HDPE, TPE, TPU, PET, PPS, POM, PBT, PMMA, PPS, SAN, etc. No of Cavities Single or Multi cavity Core Material 2344, S136,H13,S7, NAK80,SS420, P20 and other steel according to customer moul

HANKING MOULD ENGINEERING LTD. [2022-08-16 11:35:25 ]

Metal Insert Molding Choosing suitable material and molding conditions, not only for products that are easily deformed and damaged (such as glass, coils, electrical parts, etc.), can also be sealed and fixed by material. Choosing a suitable mold structure, the insert product can

Unique Solutions Mold [2022-08-15 14:46:03 ]

Medical TPE Mold Design is the source of a high-quality mold, one good mold design will be half success, USM uses the world\'s leading software to analyze products and make DFM reports and mold flow analysis to eliminate the appearance of defective and defective products from the

Unique Solutions Mold [2022-08-15 14:44:39 ]

MIM is a repeatable process for complex components made from high-temperature alloys. MIM parts are near fully dense, which provides excellent mechanical, magnetic, corrosion, and hermetic sealing properties, and allows secondary operations like plating, heat treating, and machin

KUNSHAN JINLONGYUAN NEW MATERIAL TECHNOLOGY CO.LTD [2022-08-15 14:39:22 ]

Overmolding mold is made of overmolding injection molding process which is a special injection molding process that can combine various materials into a single part. Through mechanical and/or chemical bonding of two plastic materials, the overmolding injection molding process can

Packson Mold Co., Ltd [2022-08-01 14:13:03 ]

Multi cavity mould is an injection mold that has more than one cavity. The shape of each cavity is the same. Multi cavity mold design is to produce multiples of the same part for high volume production since it means each production will produce a large number of finished parts.

Packson Mold Co., Ltd [2022-08-01 14:12:25 ]

With more than 20 years of experience in clean room injection molding, as the medical silicone molding company in China, we specialize in various clean room injection molding process techniques including medical silicone injection molding and medical grade silicone injection mold

Packson Mold Co., Ltd [2022-08-01 14:11:44 ]

Packson is not totally the same as other medical molding companies. Because we are an ISO-certified medical molding provider. Packson had got the certification of ISO 13485 2018 and ISO 9001 2008. We\'ve been working with healthcare and medical companies like BD, Wondfo since 200

Packson Mold Co., Ltd [2022-08-01 14:10:26 ]

Product Development Our company is not engaged in product development, but we are willing to assist customers to design product appearance and product structure in case of customer demand. After the product design drawings are reviewed and confirmed by customers, we provide custo

Glitter Mold Technology Co., Ltd [2022-07-18 11:30:47 ]

Mould Spare Parts Plastic mold accessories include single section shoot, double section shoot, double section shoot, flat tip, flat tip, positioning column, plastic mold guide sleeve, straight sleeve, middle column sleeve, plastic mold guide sleeve, etc. Features of Mould Spare P

Glitter Mold Technology Co., Ltd [2022-07-18 11:30:10 ]

Mould Base After years of development, mold base production industry has been quite mature. Large plastic injection molding companies can purchase customized mold base according to individual mold needs, and also choose standardized mold base products. Features of Mould Base The

Glitter Mold Technology Co., Ltd [2022-07-18 11:28:04 ]

Injection Moulding Products GM-TECH has been manufacturing tools for injection molding of plastics for various industries for more than 10 years. We are also experienced in the automotive, electrical, and home appliance industries but also manufacture moulds for other industries

Glitter Mold Technology Co., Ltd [2022-07-18 11:25:17 ]

Home Appliance Part The development and design of plastic injection molding home appliance parts pay attention to safety and health. In-home appliance industry, polypropylene plastics are used extensively in washing machines and dishwashers. As one of the leading plastic injectio

Glitter Mold Technology Co., Ltd [2022-07-18 11:19:26 ]

A multi cavity mold can be understood, obviously referring to mold with multiple cavities. The multi 8 cavity mold comprises a multi-cavity of the same plastic part and a multi-cavity of different plastic parts. The use of multi-cavity molds for plastic injection molding of plast

HANKING MOULD ENGINEERING LTD. [2022-06-21 13:42:34 ]

Insert Molding Technologies for Automotive Industry Mould Type Automotive Sensor Plastic Injection Mould Production Material Nylon PA66 No of Cavities 4 cavities Core Material S7 Cavity Material S7 Mold base steel 1.1730 with A/B plate 1.2312 Injection System Cold runner Type of

HANKING MOULD ENGINEERING LTD. [2022-06-21 13:41:51 ]

What is medical insert molding? Insert molding tooling refers to a molding process in which an integrated product is made by inserting a pre-prepared metal material insert into a mould and then injecting the plastic resin, and the molten material is bonded to the insert, cooled a

HANKING MOULD ENGINEERING LTD. [2022-06-21 13:41:29 ]

Among the three key elements of injection molding industry, material, machine and mould, the plastic injection mould is the most important and changeable one. It brings countless changes to plastic products. And because of the variety of products, processes and materials, the mou

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-05-23 10:19:17 ]

Recycling Chapter BAR Good Quality High Precision Recycling Chapter As a mould making company, we provide you with different types of injection molding with metal inserts and outsert molding, such as overmoldin`g insert molding, cavity insert injection molding, metal insert plast

Haier Digital Technology (Qingdao) Co., Ltd. [2022-05-16 14:23:22 ]

Electronics Product Part With the fast growth in the electronic industry, the demand for injection molding electronics is much higher. The injection molding electronics can be intricate or simple. Intricate injection molding electronics can be economical because they combine many

Glitter Mold Technology Co., Ltd [2022-04-27 09:21:05 ]

Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The electronics plastic injection mold has been widely applied to various industries. As a result, electronics plastic moulded products manufacturers ha

Glitter Mold Technology Co., Ltd [2022-04-27 09:20:36 ]