It is a complex task to design plastic parts involving many factors according to varoius requirements for different industires. \"How is the part to be used?\" \"How does it fit to other parts in the assembly?\" \"What loads will it experience in use?\" The plastic injection mold

HANKING MOULD ENGINEERING LTD. [2023-02-14 17:34:05 ]

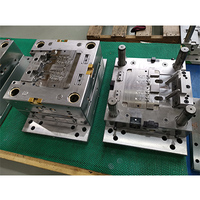

Mould Name Plastic Insert Mold Part Material PA + Glassfiber Product Size 11*30*1.3 Product Description Stator Mould Cavity 4 Cavities Mould Cavity Steel S7 Mould Injection System runner Mould Ejection System ejector Mould Cycle Time 26\'s Mould Life Cycle 1,000,000 Delivery/Lead

HANKING MOULD ENGINEERING LTD. [2023-02-14 17:32:58 ]

Product material PP material in medical-grade Mold steel S136 HRC 52-54 Mold life 1 million Hot runner brand Incoe Mold base LKM Surface finishing Mirror polishing Mold lead time 6 week What is the plastic injection molding medical parts? Medical-grade polypropylene and medical-g

Unique Solutions Mold [2023-02-06 09:41:25 ]

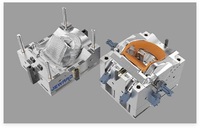

Gas & Water Assisted Injection Mold Since the thermal conductivity and heat capacity of water are much bigger than nitrogen, so the injection cycle of water-assisted is about 70% shorter than the injection cycle of gas assisted injection molding; The product wall thickness of wat

Unique Solutions Mold [2023-02-06 09:38:06 ]

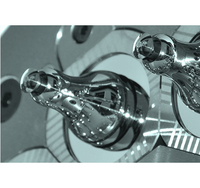

Hot Runner and Cold Runner Mould Generally, the temperature-sensitive wire is composed of steel wire insulated with a heat-sensitive material, the temperature sensing wire is commonly known as the \"thermocouple\", and there are many types, but hot runner thermocouple has two typ

Unique Solutions Mold [2023-02-06 09:34:48 ]

Green Vitality Industry is a full-service mold manufacturer specializing in plastic injection mold design & engineering support, injection mold manufacturing, and qualifying of plastic injection molds. Green Vitality operates plastic injection molding machines ranging from 80T to

Green Vitality Industry Co., Limited [2023-01-09 11:02:26 ]

Home appliance mold combines different types of molds such as gold stamping mould, plastic mould, and adsorption mould together. Therefore, household appliances are closely related to china home appliance mold . As a leading home appliance china plastic injection molding company,

Glitter Mold Technology Co., Ltd [2023-01-06 09:50:19 ]

With the fast growth in the electronic industry, the demand for injection molding electronics is much higher. The injection molding electronics can be intricate or simple. Intricate injection molding electronics can be economical because they combine many parts into one piece whi

Glitter Mold Technology Co., Ltd [2023-01-06 09:50:00 ]

Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The in mould electronics has been widely applied to various industries. As a result, electronics injection mold manufacturers have been talking about ra

Glitter Mold Technology Co., Ltd [2023-01-06 09:49:44 ]

As the foundation of the automotive industry, injection molding automotive parts are necessary factors to support the sustainable and healthy development of automotive mold manufacturers. In particular, the current independent development and innovation in the automotive parts mo

Glitter Mold Technology Co., Ltd [2023-01-06 09:48:47 ]

2k injection moulding is a manufacturing process that refers to molding two materials or colors into one plastic part. This technology combines two materials or two colors into one ending plastic part by using a 2K automotive plastic injection moulding machine. The selection of t

Glitter Mold Technology Co., Ltd [2023-01-06 09:48:29 ]

MIM China is a repeatable process for complex components made from high-temperature alloys. MIM parts are near fully dense, which provides excellent mechanical, magnetic, corrosion, and hermetic sealing properties, and allows secondary operations like plating, heat treating, and

KUNSHAN JINLONGYUAN NEW MATERIAL TECHNOLOGY CO.LTD [2023-01-06 09:28:12 ]

120L GARBAGE BIN MOULD DETAILS Product Description 120L Wheeled Garbage Bin Item No. JG04-1 Product Material PP Product Size 550x490x840mm Product Weight 7000g Total Mould Quantity 4 sets Max. Injection Machine Required 1200T Injection Machine 1600T RELATED WASTE BIN MOULD 6L/12L

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-12-26 11:41:25 ]

Among the three key elements of injection molding industry, material, machine and mould, the plastic injection mould is the most important and changeable one. It brings countless changes to plastic products. And because of the variety of products, processes and materials, the mou

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-12-26 11:40:44 ]

For medical plastic components manufacturer, it means that medical supervisors are required to supervise and manage the materials used to manufacture the equipment, the medical injection molds parts are designed to withstand high temperatures and chemical corrosion. In this way,

Unique Solutions Mold [2022-12-15 14:30:52 ]

ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability With more than 20 years of experience in clean room injection molding, as the medical device clean room injection manufacturer in China, we specializ

Packson Mold Co., Ltd [2022-12-09 09:22:01 ]

ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability Packson is not totally the same as other medical plastic injection molding companies. Because we are an ISO-certified medical injection molding provi

Packson Mold Co., Ltd [2022-12-09 09:21:35 ]

ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability With more than 20 years experience of injection molding industry and equipped with ISO Class 8 Clean Room, as the injection moulding suppliers , we o

Packson Mold Co., Ltd [2022-12-09 09:21:08 ]

Plastic Injection Molds for Sale ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability Packson is the OEM injection mold maker in china . We can supply custom injection molding parts. Our high quality an

Packson Mold Co., Ltd [2022-12-09 09:20:43 ]

ISO Class 8 Clean Room Quality Control Low & High Volume Manufacturing Competitive Price Reliability and Stability For more than 15 years, Packson Mold has become an excellent manufacturer that is enabled to make parts with high tonnage and large size thanks to ou

Packson Mold Co., Ltd [2022-12-09 09:19:26 ]