plastic machine nano infrared heater advantages 1. Improve electro thermal conversion rate – over 99.8% (nano carbon silicon material) . 2. Improve heat transmission efficiency (zero medium heat radiation, specific wave length infrared radiation). 3. Reduce heat loss (thick nan

Qingdao ZhongBangLing Electric Co., Ltd. [2016-12-20 16:32:31 ]

Introduction of Ceramic Band Extruder Heater Ceramic Band Extruder Heaters are specifically designed for high operating temperature applications. The external temperature of a ceramic band is approximately 400°F while the operating temperature can reach approximately 1400°F. Ce

Qingdao ZhongBangLing Electric Co., Ltd. [2016-12-20 16:31:29 ]

Depending on specific application requirements, the number and layout of this item can be combined into one system. As the extrusion cylinder is completely covered, it has a uniform temperature flow. Also due to the enlarged surface of heating radiation, the efficiency is improve

Qingdao ZhongBangLing Electric Co., Ltd. [2016-12-20 15:24:31 ]

Air cooling heater is mainly used for complete extrusion parts. It consists of several heaters connected with temperature reducing systems. Depending on specific application requirements, the number and layout of this item can be combined into one system. As the extrusion cylinde

Qingdao ZhongBangLing Electric Co., Ltd. [2016-12-20 15:21:23 ]

Description of Cast in iron heaters Cast in heater use tubular electric heater element as heating element,with high quality material for the shell to moulding an electric heater, which uses temperature is generally between 150 to 700 ℃. It can be widely used in plastics machine

Qingdao ZhongBangLing Electric Co., Ltd. [2016-12-20 15:20:47 ]

Cast-in heater Description Cast-in heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round, flat, rectangular, air-cooled, water-cooled and

Qingdao ZhongBangLing Electric Co., Ltd. [2016-12-20 15:19:27 ]

Cast-in heater Description Cast-in heater is a tubular electric heating element for heating body, and bending molding, into the mold with high quality metal alloy material for shell in centrifugal cast into various shapes, a round, flat, rectangular, air-cooled, water-cooled and

Qingdao ZhongBangLing Electric Co., Ltd. [2016-12-20 15:16:56 ]

The cast copper/bronze/brass heaters are mainly used for extrusion and casting moulding machines. It has a wide application in various machinery industries. The operation temperature can reach up to 650°C (bronze). In order to concentrate the heat to one direction on the injecti

Qingdao ZhongBangLing Electric Co., Ltd. [2016-12-20 15:11:45 ]

a This carbonated beverage filling equipment adopts bottle neck holding transmission technology to realize fully automatic rinsing,filling and capping. b It is equipped with CO 2 accuracy pressure control,so that the liquid level is always stable. c The application of alarm devic

TSP Packaging Machinery Co., Ltd [2016-12-19 12:23:10 ]

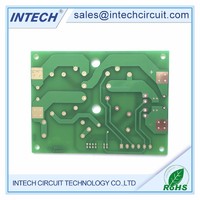

20 years in pcb field printed circuit board pcb manufacturing pcb supplier item technical parameters specifications min. line width 1-40layers min. line space 2mil/2mil Partial 2mil lines is allowed min annular ring width 2mil/2mil Partial 2mil lines is allowed min. hole size via

Intech Circuit Technology Co.,Ltd [2016-12-19 10:56:50 ]

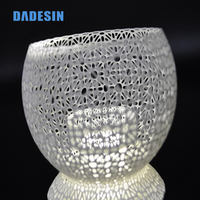

3D printing is a rapid prototyping technology, which is based on a digital model file, the use of powdered metal or plastic and other materials can be bonded by layer by layer to construct the object technology. 3D printing is usually used as a digital technology to achieve the m

Shenzhen Dadesin Rapid Prototype Co.,LTD [2016-12-16 14:17:09 ]

3D printing is usually used as a digital technology to achieve the material printer. Often used in the field of mold manufacturing, industrial design and other fields are used to create a model, and then gradually used for direct manufacturing of some products, there have been th

Shenzhen Dadesin Rapid Prototype Co.,LTD [2016-12-16 14:15:53 ]

3D printing is a rapid prototyping technology, which is based on a digital model file, the use of powdered metal or plastic and other materials can be bonded by layer by layer to construct the object technology. 3D printing is usually used as a digital technology to achieve the m

Shenzhen Dadesin Rapid Prototype Co.,LTD [2016-12-16 14:14:12 ]

Sheet metal has the advantages of light weight, high strength and conductivity (can be used for electromagnetic shielding), low cost, mass production and good performance characteristics, widely used in electronics, communications, automotive, medical equipment and other fields,

Shenzhen Dadesin Rapid Prototype Co.,LTD [2016-12-16 14:11:25 ]

Vacuum casting or silicone molding technology uses the model which produces by CNC machining or 3D printing method, to make the silicone mold in vacuum. And uses PU material to fill out silicone mold cavity in vacuum, to form the exact same model as the prototype. Silicone Mold m

Shenzhen Dadesin Rapid Prototype Co.,LTD [2016-12-16 14:07:10 ]

In rapid prototyping industry, Vacuum casting or Silicone molding is a very common method. It is mainly used in making plastic product at low volume Usually, if prototype with quantity of dozens to hundreds pieces, Vacuum casting or Silicone molding is the most economic way Due t

Shenzhen Dadesin Rapid Prototype Co.,LTD [2016-12-16 14:04:49 ]

Vacuum casting or silicone molding technology uses the model which produces by CNC machining or 3D printing method, to make the silicone mold in vacuum. And uses PU material to fill out silicone mold cavity in vacuum, to form the exact same model as the prototype. In rapid protot

Shenzhen Dadesin Rapid Prototype Co.,LTD [2016-12-16 14:04:03 ]

Vacuum casting or silicone molding technology uses the model which produces by CNC machining or 3D printing method, to make the silicone mold in vacuum. And uses PU material to fill out silicone mold cavity in vacuum, to form the exact same model as the prototype. In rapid protot

Shenzhen Dadesin Rapid Prototype Co.,LTD [2016-12-16 14:01:56 ]

It is the most direct and effective way to find defects, product design deficiencies and shortcomings So as to make improvement, until not find any defects from individual prototype. At this point, usually require small batch trial and then find out the deficiency in the batch to

Shenzhen Dadesin Rapid Prototype Co.,LTD [2016-12-16 14:00:28 ]

Usually when a product design finished, it needs to make the prototype. So prototype is the first step to verify the feasibility of the product It is the most direct and effective way to find defects, product design deficiencies and shortcomings So as to make improvement, until n

Shenzhen Dadesin Rapid Prototype Co.,LTD [2016-12-16 13:58:15 ]