Pressed Wool Felt

Specifications

Pressed Wool Felt - Produced According to SAE Standrad

Pressed wool felt production is an complex process, in our daily life, if you wash the woolen sweater by hot waters, the woolen sweater will be shrink, harden and solid, this is the basic principle of wool felting, so the pressed wool felt is also called wet wool felt.

Wool fibers have several barbs, which cannot be seen by our eyes. When the wool fibers are treated by hot water process, the barbs will be open and erect. After a continuous process of pressure, moisture and vibration, the barbs will interlock together and form a felting condition. The grade of pressed wool felt is according to the SAE standard, which determines wool content, density and other physical and mechanical properties of the felt.

The pressed wool felt can be supplied in sheet or rolls. It is the raw material of wool felt polishing wheel and wool felt bobs.

Specifications

- Material: natural wool.

- Thickness: 3/64" - 1". Special thickness can be customized.

- Colors: white, gray, black and other colors can be customized.

- Width: 60" and 72". Other widths are available.

- Length: according to customers' requirements.

| Item | SAE standard | C-F-206G | color | Wool content | Density LBS/SQYD@1" | Width | Thickness |

| EPWF-01 | F-1 | 16R1 | white | 95% | 16 | 60" | 1/8" - 1.0" |

| EPWF-02 | F-2 | 16R2 | pink | 90% | 16 | 60" | 1/8" - 1.0" |

| EPWF-03 | F-3 | 16R3 | gray | 85% | 16 | 60" | 1/8" - 1.0" |

| EPWF-04 | F-5 | 12R1 | white | 95% | 12.24 | 60" | 1/8" - 1.0" |

| EPWF-05 | F-7 | 12R3 | gray | 80% | 12.24 | 72" | 1/8" - 1.0" |

| EPWF-06 | F-10 | 9R1 | white | 95% | 8.48 | 72" | 1/8" - 1.0" |

| EPWF-07 | F-11 | 9R2 | gray | 87% | 8.48 | 72" | 1/8" - 1.0" |

| EPWF-08 | F-13 | 9R4 | gray | 75% | 8.48 | 72" | 1/8" - 1.0" |

| EPWF-09 | F-50 | 16R1X | white | 95% | 16 | 60" | 1/16" - 3/32" |

| EPWF-10 | F-51 | 16R3X | gray | 92% | 16 | 72" | 1/16" - 3/32" |

| EPWF-11 | F-55 | 12R1X | gray | 75% | 12.24 | 72" | 1/16" - 3/32" |

| EPWF-12 | F-55 black | 12R3X | black | 75% | 12.24 | 72" | 3/64" - 1/8" |

| Note: thickness more than 1" can be customized. |

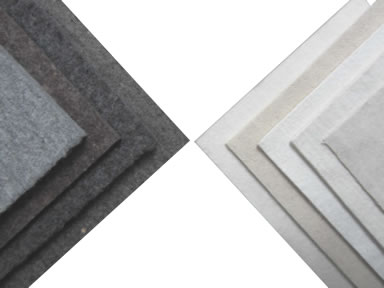

Pressed wool felt have different colors.

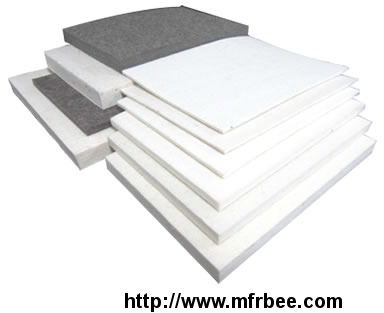

Pressed wool felts have various thicknesses.

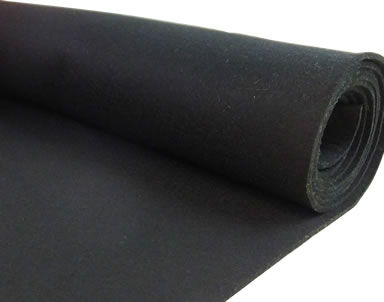

Black pressed wool felt roll.

White pressed wool felt roll.

Features

- Firm. The fiber barbs are interlocked together tightly and will not unravel.

- Abrasion resistance. The pressed wool felt has a strong structure which is abrasion resistance.

- Highly absorbent. The pressed wool felt has outstanding water absorption.

- Fire-retardant. Wool felt has naturally fire retardant, which enable the long service life and can be used in the flammable areas.

- Natural and hypo-allergenic. All of the material of wool felt are natural and without any chemical or other harmful element in it.

- Low noise. Presses wool felt used in the furniture can reduce noise and protect floor.

- Customized. The thickness, colors and sizes of pressed wool felt can be customized according to the customers' requirements.

Application

The pressed wool felt is widely used in the industrial applications.

- Pressed wool felt has outstanding abrasion resistance. It is widely used in the polishing industries as wool felt polishing wheel or wool fel bobs.

- It is widely used as the wool felt sealing products for oil sealing.

- The pressed wool felt can reduce noise, so it can be made into various accessories used in the furniture as felt furniture padto reduce noise and protect furniture.

Pressed wool felt is widely used as polishing wheel for glass polishing.

Pressed wool felt can be used in the furniture for skid resistance, low noise and floor protector.

- Country: Afghanistan

- Market: Asia

- Address: Xiao Zhangzhuang village, Chuiyang County, Nangong City, Hebei Province, China.

- Contact: Benwen Qi