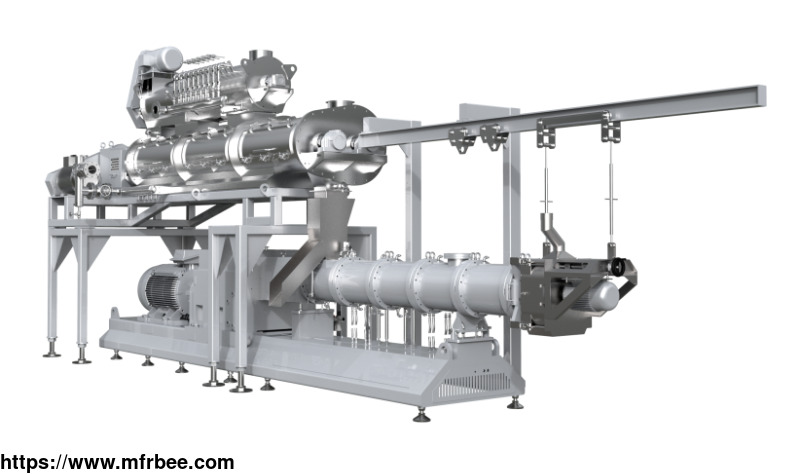

Twin-screw Feed Extruder

Product Quick Detail

- FOB Price

- USD $2,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- N/A

- Delivery

- 45 Days

Specifications

What is a Twin-screw Feed Extruder?

The H series twin-screw feed extruder is primarily used for the production and processing of various floating, sinking, and slow-sinking aquatic feeds. It can meet various customer demands, including 0.6mm aperture floating and 0.8mm aperture sinking small particles, low-starch formulations, high-protein, high-fat California seabass, and large-grain grouper. It can be equipped with vacuum extraction and pressure density control systems, combined with a fully automatic control system to ensure equipment stability and enhance the quality of extruded products.

Twin-screw Feed Extruder Features

1. High productivity, low energy consumption

The new H series twin-screw extruder adopts a 20:1 length-to-diameter ratio and stabilized screw combination technology, allowing for advantageous productivity in both floating and sinking aquatic feeds. When producing seawater floating fish feed, the capacity surpasses similar domestic models by 15-20%, with energy consumption as low as 23-25 kW.h/t.

2. Wide processing range, low production costs

The processing range covers various high, medium, and low-grade formula floating, sinking, and slow-sinking feeds. It can produce 0.6mm aperture floating and 0.8mm aperture sinking small particles. Through technological innovation, the H series extruder effectively addresses issues encountered in low-starch formula production, such as poor water stability, inadequate particle uniformity, and aesthetics, improving aquatic animal feed intake, digestion efficiency, growth performance, and quality.

3. Uniform particle distribution

Utilizing full kneading screw technology, stabilized screw configuration, high-precision screws and liners, and dual-die discharge device optimize pre-die pressure distribution, ensuring particle uniformity.

4. Effective puffing and maturation of particles

Equipped with an efficient triple-axis conditioner and unique water-steam co-injection structure, ensuring thorough mixing of water vapor and materials. Utilizing EDEM simulation technology for sectional function zoning of the conditioner, optimizing blade arrangement, enhancing material filling, extending effective conditioning time, and improving conditioning effects.

5. Stable operation, safety, and reliability with a low failure rate

Designed and processed according to European and American standards, the gearbox features 5-level high-precision gears, equipped with branded bearings and oil seals, ensuring efficient transmission, and stable and reliable operation. The new wear-resistant alloy screws offer a lifespan of over 50,000 tons.

- Country: China (Mainland)

- Business Type: Henan Herm Machinery Co., Ltd.,Manufacturer

- Market: Africa,Middle East

- Founded Year: 2010

- Address: No.50 Futing Road, Fugou Industrial Park,Fugou County

- Contact: Merry Zhang