Mixed Plastic Recycling Extrusion & Injection Molding Machine

Product Quick Detail

- FOB Price

- USD $300.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- Fuyang City, China

- Packaging

- According to customer requirements

- Delivery

- 90 working days

Specifications

The equipment we have developed includes: one-step extrusion molding equipment for mixed waste plastic films; two-step extrusion molding equipment for mixed waste plastics; co-directional flat one-step extrusion molding equipment; single-station and double-station extrusion molding equipment for higher production efficiency.

Plastic recycling molding machine solves the worldwide problem that mixed plastics waste is difficult to be reused, and truly enables mixed waste plastics to achieve green recycling and high-value utilization. We can also formulate sustainable anti-expansion solutions and tailor-made equipment according to customers\' raw materials and requirements.

How Does Mixed Plastic Recycling Extrusion & Injection Molding Machine Work?

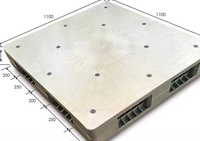

Plastic pollution has become one of the most pressing environmental concerns, as the rapidly growing production of single-use plastic products outstrips the world\'s ability to deal with them. Plastic pollution is most pronounced in developing countries in Asia and Africa, where waste collection systems are often inefficient or non-existent. But developed countries, especially those with low recycling rates, also struggle to properly collect waste plastic. To this end, we have developed mixed recycled plastic molding machine like recycled plastic extrusion machine, and granulation equipment for processing, and then use \"mixed waste plastic extrusion molding equipment\" to make the products we need, trays, manhole covers, flower pots and other products.

Through the design of the barrel and the screw, the main difficulties of mixing, dispersing, plasticizing and mixing mixed waste plastics can be solved;

Through technical research, the measurement problem of products has been solved;

Through the improvement of the storage system, the problem of insufficient injection force has been solved;

Realize intelligence through automatic design.

As a professional plastic recycling machine factory, we provide plastic recycling machine in china, extruding recycled plastic, extrusion recycling, waste plastic extrusion machine, recycled plastic extrusion, etc. Want to know more, contact us.

- Country: Afghanistan

- Contact: gwrecycling machines