Butterfly Valve

Specifications

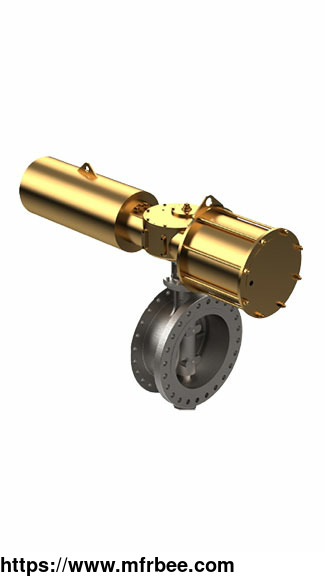

UTMOST, as a professional butterfly valve factory, is devoted to providing high performance butterfly valve wholesale. The wholesale butterfly valve is at a good price. A full selection of butterfly valve materials including carbon steel, stainless steel, heat-resisting steel, alloy steel. Inconel, Monel, and Hastelloy alloy are on offer; actuators are both on electric and pneumatic options; And the inside nominal diameter ranges between DN50(2\") and DN1200(48\"), with nominal pressure from PN16(ANSI150) to PN400(ANSI2500), connection industrial valves types included WAFER/LUG/FF/RF/RTJ. We offer soft seal butterfly valve, double eccentric butterfly valve, Eccentric butterfly valves, Fluorine-lined butterfly valve in china, triple offset butterfly valve, high-performance butterfly valve, cryogenic butterfly valve and concentric butterfly valve for sale at good prices. Contact us now!

Types of Butterfly Valve Wholesale

Soft Seal Butterfly Valves

The soft seal centerline buttress butterfly valve developed by our factory, double eccentric flange butterfly valve with compact structure, easy 90℃ rotary switch, reliable seal, and long service life.

Double Eccentric Butterfly Valve

The wholesale double eccentric butterfly valve has a structural feature that the center of the valve shaft is relatively eccentric to the center line of the valve body and the center line of the valve plate seal.

Eccentric Butterfly Valve

Eccentric butterfly valves are divided into single eccentric butterfly valves, double eccentric butterfly valves, triple eccentric butterfly valves, and variable eccentric butterfly valves.

Fluorine Lined Butterfly Valve

Fluorine-lined butterfly valve, rubber-lined butterfly valve, as a component used to realize the on-off and flow control of the pipeline system, has been extremely widely used in many fields such as petroleum, chemical industry, metallurgy, water, and electricity.

Triple Eccentric Butterfly Valve

The elasticity of the composite metal seal makes the wholesale triple offset butterfly valve have zero leakage performance.

High Performance Butterfly Valve

The high-performance butterfly valve is a new type of butterfly valve designed on the basis of absorbing the advantages of several different structure butterfly valves.

Concentric Butterfly Valve

As a component used to realize the on-off and flow control of the pipeline system, the centerline butterfly valve has been extremely widely used in many fields such as petroleum, chemical industry, metallurgy, and hydropower.

Cryogenic Butterfly Valve

The cryogenic butterfly valve developed and manufactured by UTMOST adopts the most advanced design concept, cryogenic treatment of raw materials, and strict control of the production process, and adopts a triple eccentric or improved triple eccentric (four eccentric) structure.

Advantages of UTMOST Butterfly Valve Wholesale

The opening and closing of China butterfly valve operation are convenient and quick, labor-saving, and the fluid resistance is small, which can be operated frequently.

Simple structure, small butterfly valve sizing, and light weight.

The mud can be transported in valve control systems, and the liquid accumulation at the pipe mouth is the least.

Under low pressure, a good butterfly valve material seal can be achieved.

Good adjustment performance of UTMOST wholesale butterfly valve installation.

Wholesale Butterfly Valve From Utmost: Butterfly Valve Supplier In China

Utmost, one of premier china valves manufacturers in China, is proud to offer a wide range of wholesale butterfly valves to meet the diverse needs of various industries. With a strong emphasis on quality, innovation, and customer satisfaction, Utmost has established itself as a trusted name in the valve manufacturing industry. Our butterfly valves are meticulously designed and crafted from high-quality materials, ensuring durability and optimal performance. As a wholesale supplier, we provide cost-effective solutions without compromising on quality. Whether you need butterfly valves for water treatment, oil and gas, or any other industry, Utmost is your go-to source for reliable and efficient valve solutions.

Butterfly Valve Working Principle

The working principle of a butterfly valve is based on a disc-shaped element that is positioned in the center of the valve body and rotates around an axis that is perpendicular to the flow of the fluid. When the valve is in the open position, the disc is parallel to the direction of the flow, and when it is in the closed position, the disc is perpendicular to the direction of the flow.

To control the flow of fluid, the operator rotates the disc by a quarter-turn of the valve handle or actuator, which changes the degree of openness of the valve. As the disc rotates, the flow of fluid is either blocked or allowed to pass through the valve body.

The disc of the butterfly valve can be designed to have a flat surface, which provides a linear flow characteristic, or a concave surface, which provides a more equal percentage flow characteristic. The flat surface disc is suitable for applications where the flow needs to be accurately controlled, while the concave surface disc is used for applications where the flow needs to be adjusted over a wide range.

Butterfly valves are commonly used in applications where there is a need for low-pressure drop and quick shut-off. They are also suitable for applications that require frequent opening and closing, such as in the control of the flow of cooling water, air, and gases.

What is the Function of Butterfly Valve

The main function of a butterfly valve is to control the flow of fluid through a pipeline. It does this by using a disc-shaped element (the \"butterfly\") that rotates around an axis perpendicular to the direction of the flow.

When the valve is fully open, the disc is parallel to the direction of the flow, allowing the fluid to pass through with minimal resistance. When the valve is fully closed, the disc is perpendicular to the flow, preventing the fluid from passing through.

Butterfly valves are commonly used in applications where there is a need for low-pressure drop and quick shut-off. They are also suitable for applications that require frequent opening and closing, such as in the control of the flow of cooling water, air, and gases.

In summary, the function of a butterfly valve is to regulate and control the flow of fluids in a pipeline, providing a reliable, cost-effective, and easy-to-use solution for a wide range of industrial applications.

Butterfly Valve vs Ball Valve

Both butterfly valves and ball valves are types of quarter-turn valves that control the flow of fluids through pipes. Here are some key differences between the two:

Design: A butterfly valve has a disc that rotates on a shaft to control flow, while an oem ball valve has a ball with a hole in the center that rotates to control flow.

Flow Control: A butterfly valve is better suited for regulating flow, while a ball valve is better for full open or full close operations.

Pressure and Temperature: Butterfly valves are typically used for low-pressure and low-temperature applications, while ball valves can handle higher pressure and temperature ranges.

Cost: Butterfly valves are generally less expensive than ball valves.

Maintenance: Butterfly valves require less maintenance than ball valves since they have fewer parts and are less prone to wear and tear.

Size: Butterfly valves are typically available in larger sizes than ball valves.

In summary, both butterfly valves and ball valves have their unique advantages and disadvantages, and the choice between the two depends on the specific application and requirements.

- Country: China (Mainland)

- Founded Year: 2004

- Address: No.1 of Hengfa road, Beisu area, Zoucheng, Jining City, Shandong Province,P.R.China

- Contact: Mark guo