Check Valves

Specifications

Check valve is a valve referred to the opening and closing parts for the circular disc and by its own weight and medium pressure to block the media flow back.

It belongs to automatic valve class, also known as check valve, check valve, return valve or isolation valve. Disc movement is divided into lifting type and swing type. Lift check valves are similar in construction to globe valves except for the lack of a stem to drive the disc. The medium flows from the inlet end (the lower side) and flows from the outlet end (the upper side). The valve is opened when the inlet pressure is greater than the sum of the weight of the disc and its flow resistance. On the contrary, the valve is closed when the medium flows backwards. Swing check valves have a tilt and can rotate around the axis of the disc, the working principle is similar to the lift type check valve.

Check valves are often used as bottom valves in pumping devices to prevent water from returning. Check valve and globe valve combined use, can play the role of safe isolation. The disadvantage is that the resistance is large, and the sealing is poor when it is closed.

Design feature of Check valve

Design API594, ASME B16.34

Testing API 598, API6D, EN12266-1

Face to face dimension ASME B16.10

Ends connection ASME B16.5, ASME B1.20.1, ASME B16.25

Pressure temperature rating ASME B16.34

Marking MSS SP-25

Non-destructive Examination VT, PT, RT, UT, MT

Weidouli supply of many types of Check Valves

Swing Flanged Check Valves

A basic swing Check valve consists of a valve body, a bonnet, and a disk that is connected to a hinge. The disk swings away from the valve-seat to allow flow in the forward direction, and returns to valve-seat when the upstream flow is stopped, to prevent backflow.

The disc in a swing type Check valve is unguided as it fully opens or closes. There are many disk and seat designs available, in order to meet the requirements of different applications. The valve allows full, unobstructed flow and automatically closes as pressure decreases. These valves are fully closed when flow reaches zero, in order to prevent backflow. Turbulence and pressure drop in the valve are very low.

Lifting Flanged Check Valves

Lift Check valves are particularly suitable for high-pressure service where velocity of flow is high. In lift Check valves, the disc is precisely guided and fits perfectly into the dashpot. Lift Check valves are suitable for installation in horizontal or vertical pipe-lines with upward flow.

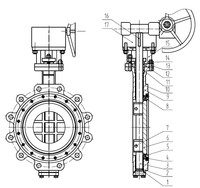

Dual plate wafer check valves

Dual Plate Wafer Check Valves were originally introduced in the late 1950s and quickly became the check valves of choice for many piping engineers because of their proven reliability and low-pressure drops. They have become the standard for process and project engineers worldwide and are used extensively in Power Plants, Refineries, Chemical Plants, Wastewater Treatment Plants and Pulp & Paper Mills.

Nozzle Check Valves

Nozzle check valves are incredibly useful for water pipelines and systems. These valves are engineered to control and protect against pressure surges that can occur in water lines. They also work to prevent water hammer and reverse flow.

Nozzle check valves are constructed with a spring-assisted disc. When fluid pressure in the valve is higher than the cracking pressure, or the pressure needed to open or close the valve, the spring lowers the disc to prevent reverse flow.

The valve is also manufactured to include a guide to keep the disc moving in a vertical. This allows it to re-seat properly.

As a professional lift check valve factory, we provide valve for sale, valve for sale, wsv valves, etc. Contact us to know valve price or more.

Weidouli Valves Co., Ltd., is a professional horizontal check valve factory, we provide china check valves.

- Country: China (Mainland)

- Business Type: Manufacturer

- Founded Year: 1989

- Address: No.20, Xingyu Road, Airport Industrial Zone, Wenzhou city, 325024 P.R. China

- Contact: wsv-valve com