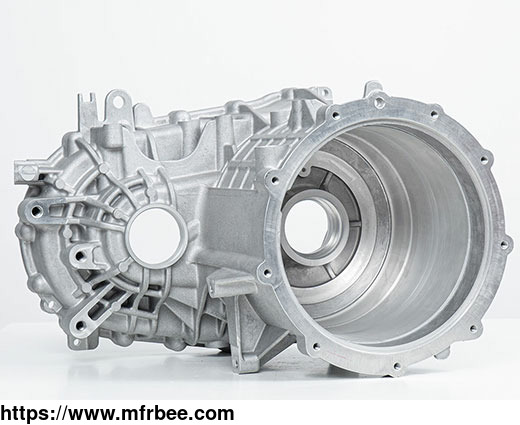

MAGNESIUM ALLOY DIE CASTING

Specifications

YiRui Metal can provide the service of magnesium die cast, provide the related magnesium alloy parts according to the customer\'s requirements, and also can produce to meet the customer\'s needs.

Cold type magnesium alloy dies casting machine(Thixo) 250T/2 sets. 500t/2 sets , 1200t/2 sets and 1600T/2 sets.

Magnesium alloys have become increasingly popular in manufacturing due to their unique properties, such as high strength-to-weight ratio and excellent machinability. One of the most common applications of magnesium alloys is in casting, where they are used to create complex shapes and structures with high accuracy.

ADVANTAGES OF MAGNESIUM ALLOY CASTING

One of the key advantages of Magnesium alloy casting is its high strength-to-weight ratio, which makes it an ideal choice for applications where weight reduction is a critical factor. Magnesium alloys are also highly machinable, which makes them easy to work with and reduces production time and costs. Additionally, magnesium alloys have excellent thermal conductivity and are highly resistant to corrosion, which makes them suitable for use in harsh environments.

CASTING PROCESS OF MAGNESIUM ALLOYS

Amagnesium alloy casting is a versatile and efficient method of creating complex shapes and structures with high accuracy. The use of magnesium alloys in casting has numerous advantages, including high strength-to-weight ratio, excellent machinability, and resistance to corrosion. The applications of Amagnesium alloy casting are diverse, spanning across industries such as aerospace, automotive, and medical. As manufacturing processes continue to evolve, Amagnesium alloy casting will undoubtedly play an essential role in creating innovative solutions for various applications.

WHY CHOOSE OUR MAGNESIUM ALLOY CASTING

Applications of Magnesium Alloy Casting

Magnesium alloy casting has numerous applications in various industries, such as aerospace, automotive, and medical. In aerospace, magnesium alloys are used to create components that are lightweight yet strong, such as engine parts and landing gear. In the automotive industry, magnesium alloys are used to create components such as transmission cases and steering wheels. Magnesium alloys are also used in medical applications, such as implants, due to their biocompatibility and corrosion resistance.

Comparison with Other Casting Materials:

When compared to other casting materials such as aluminum, steel, and titanium, Amagnesium alloys have some distinct advantages. Magnesium alloys are lighter than steel and titanium and have better corrosion resistance than aluminum. Additionally, magnesium alloys have better thermal conductivity than both steel and titanium.

Sustainability and Environmental Impact:

Using magnesium alloys in casting processes can have positive impacts on sustainability and the environment. Magnesium is abundant in nature and can be easily recycled, reducing the need for mining and refining raw materials. Additionally, the lightweight properties of magnesium alloys can contribute to improved fuel efficiency in transportation, leading to reduced greenhouse gas emissions.

Safety Considerations:

There are some safety considerations associated with working with magnesium alloys, such as the risk of fire and explosions. It is essential to follow safety guidelines and use proper equipment when handling magnesium alloys.

Die Casting Properties of Magnesium Alloy

Die-casting magnesium alloy is similar to die-casting aluminum alloy and die-casting zinc alloy, with low liquid viscosity, good fluidity and easy filling of complex cavities, and can be used for die-casting thin-walled parts without defects such as hot cracking and insufficient pouring.

The melting point and latent heat of crystallization of die cast magnesium are lower than those of aluminum alloy, and its solidification speed is fast after mold filling, and its productivity is 40%~50% higher than that of aluminum die-casting, up to twice that of die-casting aluminum. In the process of die-casting, the thermal shock to die-casting die is smaller than that of aluminum alloy, so it can be used for die-casting thin-walled parts without defects such as hot cracking and under-casting, and it is not easy to stick to die, and its service life is 2~4 times longer than that of aluminum alloy.

Magnesium alloy die-casting basically does not react with iron, and it is not easy to stick, which reduces the thermal fatigue of die-casting die. The service life of die casting magnesium is 2~4 times longer than that of aluminum alloy. At the same time, it does not erode the steel crucible, thus avoiding the pollution of the crucible to the magnesium alloy liquid.

There are many magnesium manufacturers, but we are one of the best choices for you.

- Country: Afghanistan

- Contact: yiruime talmg