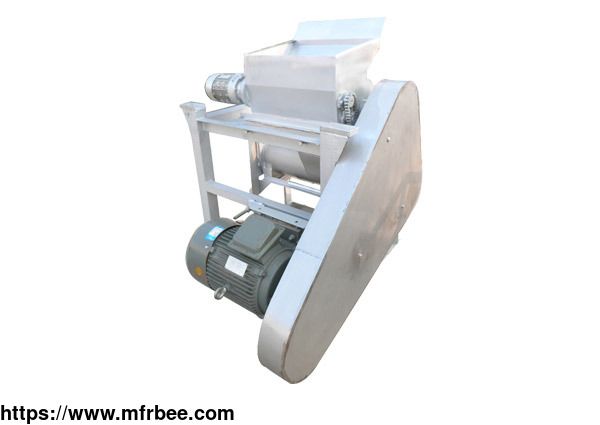

Cassava Grinding Machine

Product Quick Detail

- FOB Price

- USD $7,800.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- HeNan Province, China

- Packaging

- Standard export wood box

- Delivery

- 30-60days

Specifications

Cassava Grinding Machine VIDEO

Features of Cassava Grinding Machine

Processing Capacity: 3-6Tons/hour

Application Scope: Grating the cassava into the slurry.

Product Introduction: Cassava grater machine, cassava grating machine, cassava grinder, cassava grinding machine for cassava flour and Garri processing.

1. The pulverizing cavity looks like a dropping cave, which can prevent the circumfluence of the raw material.

2. The hidden rotors can pulverize the materials completely.

3. Two level pulverizing: rasp-type and hammer-type pulverizing with super efficiency.

4. The distance between sifter and sinker is adjustable, which can make rough pulverizing, fine pulverizing and micro pulverizing are available in one machine.

5. Easy-open door makes maintains convenient.

6. The sieve will be bounded up after pressing. This enables the replacement much easier and can close much tighter.

Product Description of Cassava Grater Machine

Cassava grater machine adopts two level pulverizing, the first level is rasp-type pulverizing, and the second level is hammer-type pulverizing, the combination of two levels sufficiently makes up their individual defects. It can be used for grating raw materials such as cassava, potato, sweet potato, yam etc. The efficiency can be improved by 45%-90% compared to the universal hammer mill.

Technical Parameters of Cassava Grater Machine

ModelNo. GD-G-660 GD-G-900

MachineMaterial StainlessSteel Stainless steel

Capacity 3Tons/Hour 6Tons/Hour

Voltage 380V &50/60Hz 3Phase 380V &50/60Hz 3Phase

Power 11KW 15KW

Weight 350KG 450KG

Dimension(L×W×H) 1300×1000×1400mm 1300×1300×1400mm

Working Principle of Cassava Grinding Machine

Grinding mechanism: The grinding mechanism is the main part of the machine responsible for grinding the cassava roots. It usually consists of a rotating drum, a set of grinding plates, or a milling chamber with sharp-edged blades. The specific design may vary depending on the type and model of the grinding machine.

In a rotating drum design, the cassava roots are fed into the drum, which rotates at a high speed. As the roots come into contact with the inner surface of the drum, they are crushed and ground into small particles.

In a grinding plate design, the cassava roots are forced between two plates with rough or serrated surfaces. The plates move against each other, effectively grinding and pulverizing the roots into a paste or flour.

In a milling chamber design, the cassava roots are introduced into a chamber with sharp-edged blades or pins. The blades or pins rotate rapidly, cutting and shearing the roots into fine particles.

Discharge chute: The discharge chute is an outlet through which the ground cassava or cassava paste/flour is released from the machine. It directs the processed cassava to a collection container or conveyor for further use or packaging.

The cassava grinding machine is powered by a motor, which provides the necessary rotational force to drive the grinding mechanism. The machine can be operated manually or automatically, depending on its design and configuration.

The ground cassava produced by the grinding machine can be used for a variety of purposes, including:

Cassava flour production: The ground cassava can be further dried and processed into cassava flour, which serves as a staple ingredient in many food products.

Cassava paste production: The ground cassava can be mixed with water or other ingredients to produce cassava paste, which is used in traditional dishes, snacks, and baked goods.

Industrial applications: The ground cassava is also used in industrial processes such as starch extraction, animal feed production, and biofuel production.

Overall, the cassava grinding machine plays a crucial role in processing cassava roots, breaking them down into more manageable forms for various applications in the food and manufacturing industries.

Main Components of a Cassava Grinding Machine

The main components of a cassava grinding machine typically include:

Hopper: The hopper is the opening or container where the cassava roots are loaded into the machine. It provides a space for holding the cassava roots before they enter the grinding mechanism.

Grinding mechanism: The grinding mechanism is the core part of the machine responsible for grinding the cassava roots. It may consist of one or more of the following components:

a. Rotating Drum: In some designs, a rotating drum is used. The cassava roots are fed into the drum, which rotates at a high speed. As the roots come into contact with the inner surface of the drum, they are crushed and ground into small particles.

b. Grinding Plates: In other designs, grinding plates are used. These plates typically have rough or serrated surfaces. The cassava roots are forced between two plates that move against each other, effectively grinding and pulverizing the roots into a paste or flour.

c. Milling Chamber: Some machines utilize a milling chamber with sharp-edged blades or pins. The cassava roots are introduced into the chamber, and the blades or pins rotate rapidly, cutting and shearing the roots into fine particles.

Motor: The motor provides the necessary rotational force to drive the grinding mechanism. It powers the movement of the rotating drum, grinding plates, or blades/pins, allowing the machine to grind the cassava roots effectively.

Discharge Chute: The discharge chute is an outlet through which the ground cassava or cassava paste/flour is released from the machine. It directs the processed cassava to a collection container or conveyor for further use or packaging.

Frame and Support Structure: The grinding machine is typically built on a sturdy frame or support structure that provides stability and strength. It ensures that all the components are properly aligned and secured during operation.

Control Panel (in some models): Some cassava grinding machines may have a control panel that allows users to adjust and regulate the speed, duration, or other parameters of the grinding process.

These are the main components commonly found in cassava grinding machines. However, it\'s important to note that the specific design and configuration of the machine may vary depending on factors such as the size, capacity, and intended use of the machine.

Advantages of Using a Cassava Grinding Machine

Using a cassava grinding machine offers several advantages, especially in the processing of cassava roots. Here are some of the benefits:

Increased efficiency: A cassava grinding machine significantly improves the efficiency of cassava processing compared to traditional manual methods. It can process a larger quantity of cassava in a shorter time, reducing the labor and time required for grinding.

Time-saving: Grinding cassava manually can be a labor-intensive and time-consuming task. With a grinding machine, the process is automated, saving a considerable amount of time and effort.

Consistent grinding quality: Grinding machines are designed to provide a consistent and uniform grinding result. This ensures that the cassava is ground to the desired texture or fineness consistently, which is important for various applications such as making cassava flour or garri.

Enhanced productivity: By using a cassava grinding machine, productivity can be significantly increased. With higher grinding capacity, more cassava can be processed within a given time, enabling producers to meet higher demands and scale up their operations.

Improved product quality: Grinding machines can produce finer and more uniform cassava particles compared to manual grinding. This contributes to better product quality, as finer particles are often preferred for certain cassava-based products like flour and starch.

Reduced labor dependency: Traditional manual grinding methods require a considerable amount of labor, which can be a limitation in terms of availability and cost. By utilizing a grinding machine, the reliance on manual labor is reduced, freeing up labor resources for other tasks and reducing labor costs.

Easy operation and maintenance: Cassava grinding machines are generally designed to be user-friendly, with simple operating procedures. They are also relatively easy to maintain, requiring routine cleaning and occasional servicing. This makes them accessible to a wide range of users, including small-scale farmers and processors.

In summary, using a cassava grinding machine offers advantages such as increased efficiency, time-saving, consistent grinding quality, enhanced productivity, improved product quality, reduced labor dependency, and easy operation and maintenance. These benefits make grinding machines a valuable tool in cassava processing, contributing to higher productivity and better overall outcomes.

We can offer sorts of cassava grinder for sale, and the cost of cassava grinding machine is reasonable, if you have needs, please contact us.

- Country: China (Mainland)

- Address: Erlangmiao Street, FangCheng County, NanYang City, HeNan Province, China

- Contact: goodway china