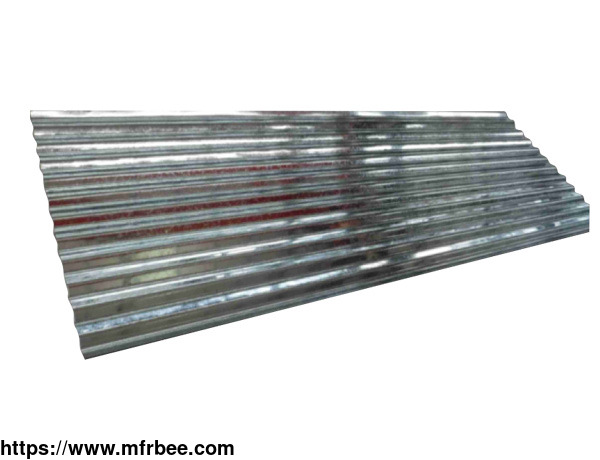

Steel Searcher Steel Supply Chain Galvanized Steel Sheet

Product Quick Detail

- Minimum Order

- 10

- Place Of Origin

- Shanghai,China

- Packaging

- Standard Export Package by bundles or customized

- Delivery

- 3-45 days

Specifications

Galvanized stainless steel sheet refers to the surface of a layer of zinc plated steel plate. Galvanizing is an economical and effective method of rust prevention that is often used. About half of the world\'s zinc production is used in this process.

Name Galvanized Steel Sheet

Standard AiSi, ASTM, bs, DIN, GB, JIS

Grade SGCC

Place of Origin China

Model Number 0.12-0.8mm*600-1500mm

Type Steel Plate

Technique Cold Rolled

Surface Treatment Coated

Application Boiler Plate

Special Use Wear Resistant Steel

Width 600mm-1500mm

Length Customer\'s requirement

Tolerance ±1%

Type Galvanized Steel Sheet

Processing Service Bending, Welding, Decoiling, Cutting, Punching, Roofing

Product Name Galvanized Steel Roofing Sheet

Keyword roofing sheet

Name Galvanized Steel Roofing Sheet

Zinc coating 40-275g/m2

MOQ 5 tons

Payment 30% deposit, 70% by T/T against B/L copy; or by L/C

Packaging Standard export Sea worhty Packaging

Product Galvanized Steel Roofing Sheet

Features of Galvanized Steel Sheet

Galvanized tile is widely used in a variety of different environments, with a long anti-corrosion life.

The treatment cost is low and the anticorrosion cost of galvanized tile is lower than that of other paint coatings.

Durable, standard galvanized rust protection requires no repair for more than 50 years in suburban environments, such as structural steel frame house. In urban or offshore areas, a standard galvanized anti-rust coating can last up to 20 years without repair.

Good reliability. The galvanized layer is metallurgically bonded to the steel and becomes part of the rigid surface, so the durability of the coating is relatively reliable.

The coating has strong toughness, and the galvanized layer forms a special metallurgical structure, which can withstand mechanical damage during transportation and use.

Integrity protection: all parts of the plated parts can be galvanized, even in depressions, sharp corners and hidden places can be fully protected.

It saves time and effort. Galvanizing construction speed is faster than other coating construction methods, which can avoid the time required for painting after installation.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: Americas,Africa,Asia

- Founded Year: 2012

- Address: No.123 Xinpei Rd, Jia Ding District, Shanghai, P.R.C.

- Contact: steel searcher