Extrusion Molding

Specifications

Extruded Molding

The products are processed by injection molding extruder, with a smooth surface and high dimensional accuracy. Products of different sizes, colors, and types can be customized according to customer requirements.

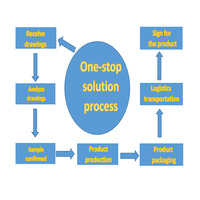

As a professional injection and extrusion molding company, ETCN provides our clients with plastic molding services of infection and extrusion stretch blow moulding services which includes two different types: intermittent extrusion blow molding and continuous extrusion blow molding.

Extrusion Molding Capabilities

Extrusion molding is mainly referred to as the extrusion of a screw or plunger to force a polymer material that is heated and melted under pressure to force it through the die to form a constant A method of forming continuous cross-section profiles. The extrusion molding process mainly includes the processes of feeding, melting and plasticizing, co extrusion blow molding, shaping, and cooling.

As a leading CNC machining manufacturing company in China, ETCN offers high-precision CNC machining and manufacturing services covering different fields in China CNC grinding services like iron metal casting services, CNC custom machining (including plastic) services, CNC milling services, CNC punching services and CNC turning services. ETCN struggles with what to call ourselves since we are not a traditional machine shop, seller, or a metal parts supplier.

- Country: China (Mainland)

- Address: Room 2310, No.39 South Chezhan Road, Hongkou District, Shanghai, China

- Contact: Ting Liang