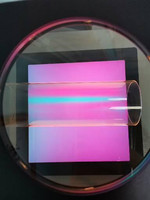

AOI DCB Automatic Ceramic Substrate Defect Inspection Equipment

Product Quick Detail

- Sample Thickness

- 1-2mm

- Object Size

- Max:190×140mm

- Weight

- 1500kg

- Detectable Flaw

- short-circuit,connecting line, chipped edge, residual copper,

- Inspecting Speed

- 9.6s/pcs

- Suitable Object

- DCB

- Dimension

- 1930mm (L) ×1430mm (W) × 1900mm (H)

- Packaging

- 1 pcs in 1 carton

- Delivery

- 90 days

Specifications

| NO | Item | Parameter |

| 01 | Suitable object | DCB |

| 02 | Object size | Max:190×140mm; |

| 03 | Sample thickness | 1-2mm |

| 04 | CCDPixel | AOI 1:13um/Pixel AOI 2/3:24um/Pixel |

| 05 | Board warpsolution | Auto focus |

| 06 | CAM format | Gerber |

| 07 | Image Processingmethod | CCDColor software |

| 08 | InspectingSpeed | 9.6s/pcs |

| 09 | Data source | CAM+graphic scanning |

| 10 | Auxiliary function | Laser marking |

| 11 | Defect Confirmation | AOIon-line |

| 12 | Positioning Way ofceramic substrate | Automatic |

| 13 | Defectsearching method | Image contrast+ logic algorithm |

| 14 | Detectable flaw | AOI 1:short-circuit,connecting line, chipped edge,residual copper,copper deficiency, copper surface stain, copper surface oxidation,cutting dislocation, ink disconnection, ink shedding, ink contamination,reverseresistance welding mark,resistance weldingdislocation,resistance weldingpinhole., etc . AOI 2:dint, scratches,wrinkles, bumps; AOI 3:bubble,indentation; |

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: G20,Americas,Europe,Middle East

- Founded Year: 2008

- Address: NO. 189 , Zhangji Road , Eocnomic Development Zone

- Contact: Jesse Cheng