Linshang LS225+F500plating thickness tester

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- 1 pcs each box

- Delivery

- 15 Days

Specifications

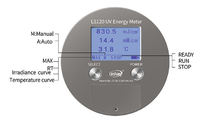

LS225+F500 is a plating thickness gauge with separate host and probe. It consists of LS225+F500 multi-probe coating thickness gauge host and F500 probe.

LS225+F500 plating thickness gauge is specially used to detect copper, zinc, tin, chromium and non-magnetic coatings on iron and other ferromagnetic metal substrates. The plating thickness gauge has ultra-high measurement accuracy and repeatability. It can be used to measure the thickness of ultra-thin coatings below 10μm.

The LS225+F500 plating thickness gauge is particularly suitable for testing small-sized materials with a minimum measurement area diameter of only 7 mm. We provide professional test fixtures for users to buy, especially suitable for the measurement of thin coating thickness of small workpieces such as screws and bolts and various irregual shaped materials.

LS225 plating thickness gauge host parameters

| Display | 240×160 dot matrix LCD |

| Power supply | 4pcs of 1.5V AAA alkaline battery |

| Operation temperature range | 0℃-50℃ |

| Storage temperature range | -20℃-60℃ |

| Host size | 148*76*26 mm (L*W*H) |

| Weight (include battery) | 194g |

2. F500 probe parameters

| Measuring principle | Magnetic Induction |

| Measuring range | 0.0-500μm |

| Resolution | 0.1μm:(0μm - 99.9μm) 1μm:(100μm - 500μm) |

| Repeatability | ≤ ± (0.8% of reading + 0.1μm) Test with fixture |

| Accuracy | ≤±(2%reading+0.3μm) after calibration of 1-5 points |

| Unit | μm / mil |

| Measuring interval | 1.5s |

| Minimum measuring area | Ø = 7mm |

| Minimum curvature | Convex:1.5mm / Concave:10mm |

| Minimum substrate thickness | 0.1mm |

| Calibration | Support zero reference adjustment and 1 to 5-points calibration |

| Probe size | 110*15 mm (Without connecting cable) |

| Probe weight (include battery) | 81g |

- Country: China (Mainland)

- Founded Year: 13

- Contact: lin shang