Industrial Molding Parts

Product Quick Detail

- FOB Price

- USD $5,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China (Mainland)

- Packaging

- PALLET

- Delivery

- 15 Days

Specifications

CustomPlastic Injection Molding

Part function: Plastic gear for industrial productsPart material: POM We are plastic mould manufacturer in China serveglobal clients. As a high quality custom injection moldmaker and plastic...

Plastic Injection Mold Inc

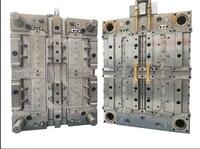

POM gear mould, is only one of the similar products we made forEurope customer. The mould is 4 cavities, short cycle time, urgentT1 schedule, HanKing finished the first of trial in 4 weeks.lead time...

Injection Mould Tooling

Part function: Plastic gear for industrial productsPart material: POM We are Injection Mould Tooling maker in China serveclients around the world. As a high quality custom injectionmold maker and...

Injection Molding Service

HanKing Mould strives to provide you with most reasonable cost plastic injection molding service while meeting all qualityrequirements of you at the same time.Common plastic injection mould steel...

Mold Making Procedure

Mold making procedure, first step is mould drawing design,the 2D & 3D mould design should be confirmed by customer.Customer send the plastic parts drawing.HanKing design tooling drawing according ...

Injection molded parts

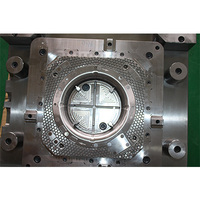

Part size: 124*152*80mmPart material: ASACavity: 2 cavitiesMould weight: 875kg Mold size: 600*610*880mmMould type: plastic injection mouldFeature: medium size plastic part, hot bush, cold runner...

Custom Plastic Parts

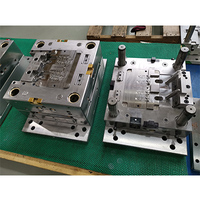

Part size: 220*172*5mmPart material: ABS 20%GFCavity: 1 cavityMould weight: 542kg Mold size: 590*590*680mmMould type: plastic injection mouldFeature: medium size plastic part, hot tip, slider core...

Industrial molding parts are referred to the plastic parts of industrialprecision molded products inc

Nowadays, the demand for consumer products is oversupplied, and the demand for industrial products is increasing. This is because many parts of the equipment in the past were made of metal. With the development of the plastics industry, more and more industrial product parts are trying plasticization. Metal parts have higher density, greater strength, and thermal and electrical conductivity. However, plastic industrial parts have advantages in mechanical shock absorption, thermal expansion, elongation at break, and toughness. And the properties of plastics can be greatly transformed by the addition of fillers, reinforcing materials and modified materials, engineering plastics perform better in this respect. Use plastic to produce parts that are not necessary for high strength can reduce the weight of equipment, simplify the structure and save costs, this is why industrial molding parts are becoming more and more common.

Industrial molding parts range from small plastic gears to large industrial equipment plastic enclosures. The design of the mold is very complicated work, the plastic part structure, the different plastic resin, required life cycle, etc. many factors determine the mold construction.

Our designers must master the properties of different plastics and mould steel, and consider the temperature change, pressure change, steel abrasion during the production process, designed qualified industrial moulds.

If the mould structure is unreasonable, even the most excellent operator can not get good plastic parts. The design defects cannot be solved by the defects in the production process. Only when all the factors are considered in the design of the mould, the mould quality and stability of the mass production can be guaranteed.

Related News

Heat Treatment Characteristics Of Custom Molds For Plastic

Development Trend of Mould Industry in China

The Basic Concept Of Plastic

What is Precision Injection Molding

Four Specific Action Areas for China\'s Injection Molding Industry

Current Situation Of Injection Molded Parts China Industry

- Country: China (Mainland)

- Founded Year: 2011

- Address: No.5, Guihua Road, Tangxia Yong Community, Songgang Town, Baoan District, Shenzhen. China.

- Contact: Yoyo Tang