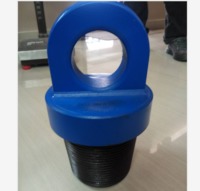

Drill Collar Slick and Spiral Drill Collar Nonmagnetic

Specifications

We supply slick drill collars, spiral drill collars and non-magnetic drill collars; their sizes are from 3-1/8 to 11 inches. Besides the drill collars in the table below, we can supply other drill collars at customers\' request.

Materials:

Drill collars are manufactured from AISI 4145H modified steel, and are supplied in the \"as rolled\" surface finish condition. Alternative surface finishes are available.

Trepanning and Heat Treatment:

Drill collars are trepanned and drifted to API Spec 7-1. Full-length heat-treatment processes ensure that mechanical properties meet or exceed API Spec 7-1 requirements. A hardness range of 285-341, Brinell hardness and Charpy \"V\" notch minimum impact strength of 40 ft-lb at 70 F are guaranteed one inch below the surface.

Traceability:

Drill collar material and process traceability are maintained from receipt of the mill\'s certified raw material to completion of manufacturing. Serial numbers are die stamped on bar bodies.

Rigid Inspection Procedures:

We inspect all our drill collars to ensure compliance with API SPEC 7-1 standards. These inspections include visual dimensional checks as well as ultrasonic inspections over the entire body of the drill collar.

Cold Rolling:

Drill collar thread roots, as well as elevator recess upper radius, are cold-rolled. Cold rolling creates a compressive recess upper radius stress condition that increases fatigue life by minimizing crack initiation.

Phosphate-coated or Copper Plating:

All connections are phosphate-coated or copper plated to improve resistance to corrosion.

Slip Groove, Elevator Groove and Size:

Materials:

Drill collars are manufactured from AISI 4145H modified steel, and are supplied in the \"as rolled\" surface finish condition. Alternative surface finishes are available.

Trepanning and Heat Treatment:

Drill collars are trepanned and drifted to API Spec 7-1. Full-length heat-treatment processes ensure that mechanical properties meet or exceed API Spec 7-1 requirements. A hardness range of 285-341, Brinell hardness and Charpy \"V\" notch minimum impact strength of 40 ft-lb at 70 F are guaranteed one inch below the surface.

Traceability:

Drill collar material and process traceability are maintained from receipt of the mill\'s certified raw material to completion of manufacturing. Serial numbers are die stamped on bar bodies.

Rigid Inspection Procedures:

We inspect all our drill collars to ensure compliance with API SPEC 7-1 standards. These inspections include visual dimensional checks as well as ultrasonic inspections over the entire body of the drill collar.

Cold Rolling:

Drill collar thread roots, as well as elevator recess upper radius, are cold-rolled. Cold rolling creates a compressive recess upper radius stress condition that increases fatigue life by minimizing crack initiation.

Phosphate-coated or Copper Plating:

All connections are phosphate-coated or copper plated to improve resistance to corrosion.

Slip Groove, Elevator Groove and Size:

Lake offers optional slip and elevator recesses to improve handling efficiency and safety. Unless otherwise specified, slip and elevator recesses are machined in compliance with API spec 7-1 guidelines.

Contact information

Attn: Melody WangMobile: 0086-18307551623 (wechat/whatsapp)

Email: melody(at)lakepetro.com

- Country: China (Mainland)

- Business Type: Trading Company

- Market: European Union

- Founded Year: 2011

- Address: Huanghe Road,Dongying City,Shandong Province, 257000, China.

- Contact: Melody Wang