6A2 vitrified bond diamond grinding cup-shaped wheel for PCD and PCBN tools

Product Quick Detail

- FOB Price

- USD $70.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- 1piece each box

- Delivery

- 10 Days

Specifications

Vitrified diamond wheel is mainly used for PCD, CVD, PCBN, cemented carbide, ceramic cutting tools and other milling cutter, drill bit , etc, with high speed and low-damage.

This kind wheel is suitable for PCD and PCBN tools high-speed & precision grinding. It solves low grinding efficiency and poor quality of the cutting edge problems for many factories. With very high sharpness, the wheel increases 1.5-3 times grinding efficiency for cutters manufacturer.

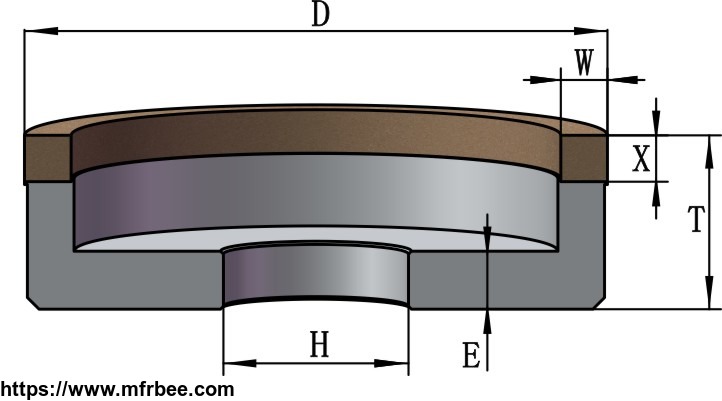

Grinding wheel specification

| Shape | D | T | H | W | X |

| 6A2 | 150 | 40 | 40 | 3/5/10/15/20 | 10 |

| Diamond Grit: 400#-5000# |

Product applications:

● Grinding parts: end surface, peripheral surface, chip breaker groove, bevel surface, hole and other parts.

● Grinding (processing) Level: Precise grinding: 0.005 mm / pass (wheel grit is finer than 800 mesh); general grinding: 0.01-0.03 mm / pass (wheel grit is finer than 500 mesh); sharp grinding: 0.05 mm / pass (wheel grit is finer than 200 mesh)

● Grinding way: wet grinding (water as a coolant)

Grit select: 400 #, 600 #, 800 # for coarse grinding, 1000#, 1500#, 2000#, 3000# for precise grinding.

Grinding parameters: grinding speed Vc =24m ~ 26m / s, when precise grinding, Vc =13 ~ 18m / s, cutting depth ap =0.01mm / double stroke.

- Country: China (Mainland)

- Business Type: specializing in resin bond, vitrified bond, metal bond and electroplated grinding wheels, saw blades and diamond microdermabrasion tips.

- Market: all around the world

- Founded Year: 2005

- Address: Building 28,Huachuang industrial park,Jinshan Avenue,Shiji Town,Panyu,Guangzhou-511450,China

- Contact: Wendy Lan