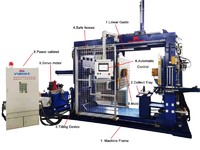

Simple operation+high quality APG machine for silicone rubber insulator

Product Quick Detail

- Place Of Origin

- China

- Brand Name

- Volmet

- Minimum Order

- 1

- Heating Plate Size

- 660X500(mm)

- FOB Price

- USD $50,000.00 / Piece

- Model No

- SVOL-665

- Packaging

- export wooden case

- Delivery

- 55 workdays

Specifications

-

volmet Electricity Technology Co.,Ltdisthe only supplier who professional produce APG machine,apg casting machine,apg clamping machine,apg clamping machine for apg process,apg epoxy resin clamping machine ,apg equipment,apg hydraulic molding machine,apg molding machine ,automatic injection moulding apg machine,epoxy insulators apg clamping machine,epoxy resin apg casting machine,epoxy resin apg clamping machine,epoxy resin apg machine,epoxy resin apg molding machine,epoxy resin hydraulic forming machine,APG molds,casting mold and instrument transformer winding machine.

Application-Standard APG clamping machine:

- This APG casting machine belong to Standard APG clamping machine, the min clamp plate size is 660X500mm, and the Max clamp plate size is: 6600X500mm, can meet production requirement from 11-36KV, such as current transformer, voltage transformer, insulator, bushing, spout, SFG gas-insulated indoor switch disconnector. Etc.

- The APG casting machine upper and lower core distance can be customized, foundation pit is necessary if lower core travel distance above 500mm.

Technical Parameters:

| SVOL-655 | ||||

| Heating plate size | Clamping force | Speed of clamping close | Clamping open speed | Distance between heating plates |

| 660X500(mm) | 150(KN) | 2.4 (m/min) | 3.3 (m/min) | 145-965 mm |

| Heating power | Hydraulic unit power | Tilting degree | Machine dimension | Machine weight |

| 12 (KW) | 2.2 (KW) | 0° or 7° | 2920X820X1450 (mm) | 2450 (KG) |

| Volmet VS Other Suppliers | ||

| Items | volmet | Other Suppliers |

| Set the machine start time | √ | × |

| Offer electronic vacuum gauge (For the vacuum stirring mixing device) | √ | × |

| Offer thin film de-gassing, excellent vacuumize (For the vacuum stirring mixing device) | √ | × |

| Offer oil cycling heating surround pot, heated evenly (For the vacuum stirring mixing device) | √ | × |

| Pressure setting and safety valve improve safety coefficient (Double insurance for the vacuum stirring mixing device ) | √ | × |

| Offer matched APG mold | √ | × |

| Offer free APG technique training | √ | × |

| Products 1:Good product quality,fine surface finish of products without bubbles. 2:High efficiency and high automation,only need 1/2 workers operate APG machine,efficiency greatly raised but the intensity of labor is decreased. 3:Chemical resistance,electrical insulation,strength resistance greatly improved. | | | | | |

APG machine produce process 4 steps:

- Install and heating mould →Pre-mixing epoxy compound →Injection →Curing

- Firstly,install mould on APG clamps →heat it up to 60°C→open mould, brush mould release agent →close mould

- Secondly,pre-mixing casting compound in vacuum pot →turn off vacuum valve when vacuum gage show -0.1→release vacuum, push vacuum pot nearby APG machine→

- Thirdly,APG Add pressure into vacuum pot and start injecting cast compound into mold, release pressure →open mold →take out products

- Fourthly ,Curing. Move product in to oven.

| Epoxy resin, curing agent, silica powder, pigment=1:1:3.5 |

- Volmet

- Volmet Companyis a professional enterprise engaged in producing the APG machine, APG Molds, Casting Molds, winding machine for CT/PT,laser marking machine,engineers who works with epoxy resin products more than 25 years, talented from product design,mold design, APG technique training overseas.guarantee training you make qualified products.

- APG Technique Traning InColombia—whole production line(APG machine,molds,windingmachine,oven, raw materials)

- Country: China (Mainland)

- Business Type: volmet Electricity Technology Co.,Ltd is the only supplier who professional produce APG machine,apg casting machine,apg clamping machine

- Founded Year: 2008

- Contact: Eda Wu