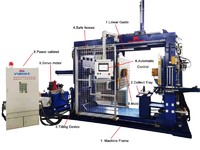

Hot sale mixing machine ( APG clamping machine )

Product Quick Detail

- Model No

- VOL-100L

- Minimum Order

- 1

- Dimension Of Mixer Device

- 1900X850X1885 (mm)

- Vacuum Pump Power

- 1.1KW,2800r/min

- Place Of Origin

- China

- FOB Price

- USD $3,000.00 / Piece

- Heating Power

- 3 (kW)

- Packaging

- export wooden case

- Delivery

- 55 woerdays

Specifications

APG Clamping Machines factory

1.high quality clamping mould

2.Supply APG moulds

3.Experienced engineers

4.Long life service

volmet Electricity Technology Co.,Ltdisthe only supplier who professional produce APG machine,apg casting machine,apg clamping machine,apg clamping machine for apg process,apg epoxy resin clamping machine ,apg equipment,apg hydraulic molding machine,apg molding machine ,automatic injection moulding apg machine,epoxy insulators apg clamping machine,epoxy resin apg casting machine,epoxy resin apg clamping machine,epoxy resin apg machine,epoxy resin apg molding machine,epoxy resin hydraulic forming machine,APG molds,casting mold and instrument transformer winding machine.

| apg machine frame | 1 set |

| electric power pack | 1 set |

| hydraulic power pack | 1 set |

| mixing frame | 1 set |

| mixing pots | 2 sets |

Main Technical Parameters

| VOL-100L | ||||

| Strirring power | Strirring Speed | Vacuum pump power | Worm gear screw jack | Vacuum degree |

| 3 (kW) | 21-118 (m/min) | 1.1KW,2800r/min | 0.37 (kW) | 1.5 (mbar) |

| Dimension of mixer device | Weight of mixing device | Pot capacity (L) | Machine dimension | Machine weight |

| 1900X850X1885 (mm) | 680 (KG) | 100L | 910X760X1565(mm) | 455(KG) |

Products

1:Good product quality,fine surface finish of products without bubbles.

2:High efficiency and high automation,only need 1/2 workers operate APG machine,efficiency greatly raised but the intensity of labor is decreased.

3:Chemical resistance,electrical insulation,strength resistance greatly improved.

| Volmet VS Other Suppliers | ||

| Items | volmet | Other Suppliers |

| Set the machine start time | √ | × |

| Offer electronic vacuum gauge (For the vacuum stirring mixing device) | √ | × |

| Offer thin film de-gassing, excellent vacuumize (For the vacuum stirring mixing device) | √ | × |

| Offer oil cycling heating surround pot, heated evenly (For the vacuum stirring mixing device) | √ | × |

| Pressure setting and safety valve improve safety coefficient (Double insurance for the vacuum stirring mixing device ) | √ | × |

| Offer matched APG mold | √ | × |

| Offer free APG technique training | √ | × |

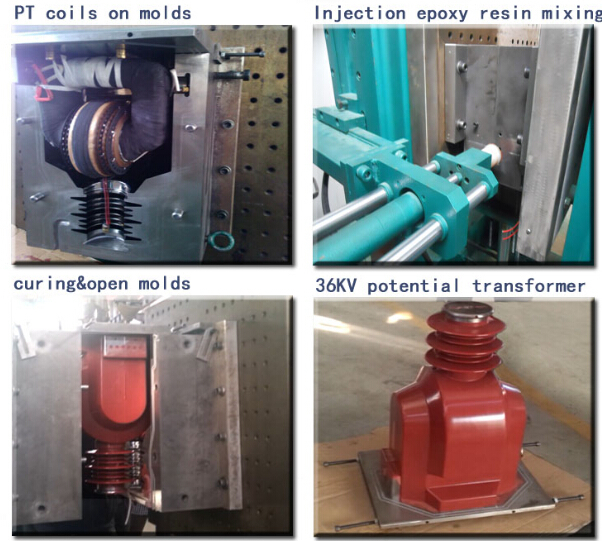

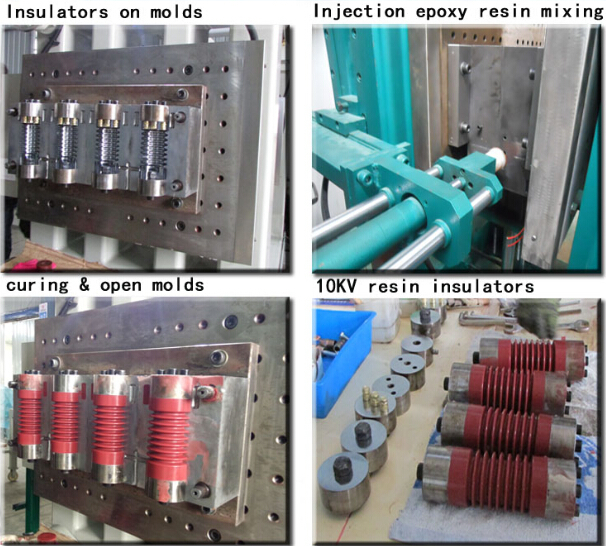

APG device working process

APG machine work process

·Products made by APG machine

Accompanying customer visits

- Country: China (Mainland)

- Business Type: volmet Electricity Technology Co.,Ltd is the only supplier who professional produce APG machine,apg casting machine,apg clamping machine

- Founded Year: 2008

- Contact: Eda Wu