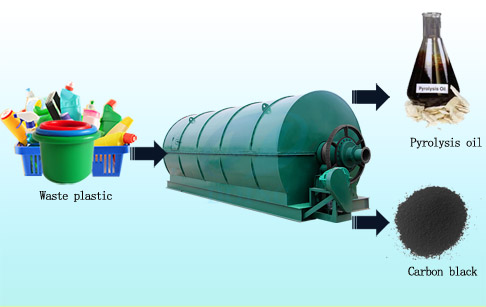

Pyrolysis plant convert plastic to oil

Product Quick Detail

- FOB Price

- USD $50,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard wooden cases pacakges

- Delivery

- 15 Days

Specifications

Have you heard of converting waste plastic into oil? That\'s right, DoingGroup already has a very maturewaste plastic pyrolysis plant

Perhaps some people do not know too much about thewaste plastic pyrolysis plant

1. The waste plastic into the reactor by automatic push device.

2. Reactor with fuel heating, reaching a certain temperature, waste plastics began to crack into oil and gas.

3. These oil and gas will enter the condensing system, a part of which will be liquefied and flow into the oil tank. The other part will be liquefied through the condensing system to liquefy into heavy oil and flow into the tank.

4. The resulting heavy oil will be filtered through the dedusting and deodorizing device. Remove fumes, dust particles generated during combustion of the fuel.

5. Wait until the temperature in the kettle drops below 40 ° C and remove the carbon black from the kettle.

Know the working principle ofwaste plastic pyrolysis plant

1. Fuel oil: Mainly used in steel plants, boiler heating, heavy oil generators, cement plants.

2. Carbon black: mainly used for pressure ball burning and refined milling. Which refined flour and can be used for new tires, rubber soles, pigment manufacturing materials.

So what are the unique advantages of ourwaste plastic pyrolysis plant

1.16mm, Q245R thick steel boiler plate, curved pressure head, can withstand high temperature and high pressure.

2. Unique 3-step welding process, longer service life.

3. Currently the most commonly used and best performing condenser in the oil industry. The cooling system of the equipment is divided into three stages to ensure that the cracked oil and gas is fully cooled and the oil yield is increased.

4. A water separator, water seal, vacuum devices and other safety devices. Can purify oil and gas, exhaust, to prevent its back. And can provide negative pressure, drainage of oil and gas.

Through the above introduction, you have a further understanding of ourwaste plastics pyrolysis plant

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email:oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com

http://www.doinggroup.com

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: European Union

- Founded Year: 1987

- Address: Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Province, China

- Contact: Boinne Zhao