Continuous process tire pyrolysis plant

Product Quick Detail

- FOB Price

- USD $300,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard wooden cases pacakges

- Delivery

- 15 Days

Specifications

Continuous process tire pyrolysis plant

Thecontinuous process tire pyrolysis plant

Continuous process tire pyrolysis plant working process

The main work flow ofcontinuous process tire pyrolysis plant

1. Withdraw the collected tires with a wire drawing machine.

2. Put the wire pulling tire into the tire crusher and break the tire into small pieces of 3-5cm.

3. Put the tire scrap into the continuous process tire pyrolysis plant and heat the reactor. After much and pyrolysis reaction and condensation finally get fuel.

4. The end of equipment operation will be automatically discharged carbon black.

Continuous process tire pyrolysis plant working process

What are the main advantages ofcontinuous process tire pyrolysis plant

1. Relative to the intermittent tire cracking equipment, the single machine processing capacity is large and the floor space is small.

2. Use PLC control system to save manpower.

3. An accurate calculation system ensures that the waste tire can be fully cracked and the oil yield is high.

4. The pyrolysis reactor adopts an internal rotation device and does not need to periodically stop the replacement of the sealing material.

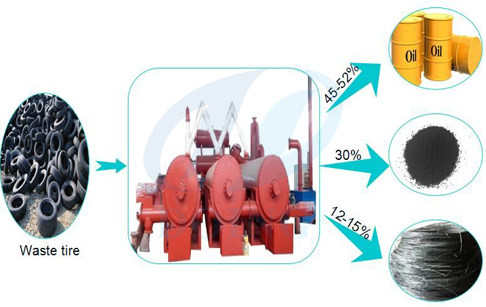

Like the intermittent tire pyrolysis plant, thecontinuous process tire pyrolysis plant

Fuel oil usage

1. Fuel oil : Mainly used in iron and steel plants, boiler heating, heavy oil generators, and cement plants.

2. Carbon black: It is mainly used for pressure ball combustion and refined milling. Refined flour can be used for new tires, rubber soles, and pigments.

3. Steel wire: Mainly used for waste recycling and recasting.

4. Combustible gas: It will be recycled by the equipment and reused in the heating fuel of the reactor.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email:oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com

http://www.doinggroup.com

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: European Union

- Founded Year: 1987

- Address: Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Province, China

- Contact: Boinne Zhao