Scrap plastic to oil by pyrolysis plant

Product Quick Detail

- FOB Price

- USD $50,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard wooden cases pacakges

- Delivery

- 15 Days

Specifications

Scrap plastic to oil by pyrolysis plant

The development of science and technology and the improvement of living standards have brought about tremendous growth in production, and various commodities have indirectly produced waste. Plastics have always been one of the materials because of their high plasticity and low cost, and therefore they have a wide range of applications. The data shows that the annual trend of waste plastics is still excessive growth. What is more serious is that the recycling cycle of waste plastics is still insufficient. There are millions of tons of waste plastics each year, landfilled and put into the ocean. This way of dealing with waste plastics is unscientific. DoingGroup has developed arecycling scrap plastic to oil by pyrolysis plant

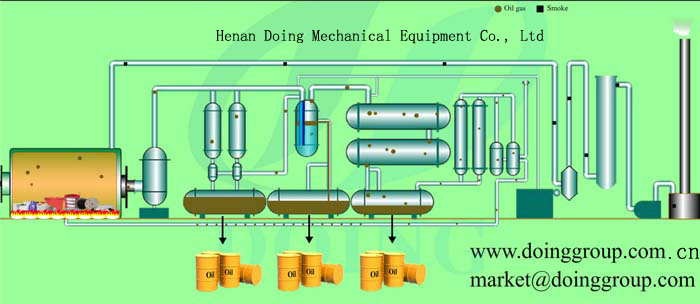

The main working flow ofrecycling scrap plastic to oil by pyrolysis plant

1. Before the waste tire is sent to the reactor, you can use a wire drawing machine to pull out the steel wire in the waste tire. This can reduce the damage to the reactor and prevent the carbon black from mixing with the steel wire after the equipment is finished refining. Of course, it can also be directly sent to the reactor, according to personal operating habits.

2. The reactor is heated with fuel. When the temperature reaches a certain height, the waste tire inside the reactor begins to undergo a cracking reaction and is cracked into oil and gas.

3. The cracked oil and gas will liquefy into heavy oil through the condensing system and fall into the oil tank. Part of the oil and gas that has not been liquefied will be filtered and liquefied into heavy oil by the condensing system. Part of the non-condensable gas will be finally recovered and used for the heating of the reactor. .

4. Finally, the heavy oil in the tank is dusted and deodorized, which is the final fuel.

5. Wait until the temperature of the reactor has dropped below 40 degrees. Remove the carbon black (steel wire) from the reactor.

So what kind of benefits will be gained from running our equipment? After our engineer’s scientific test, running our equipment can earn nearly $2,000 in revenue a day. These benefits mainly come from cracked 45-50% of the fuel, 30% of carbon black, and 15% of waste steel wire. Their specific uses are as follows:

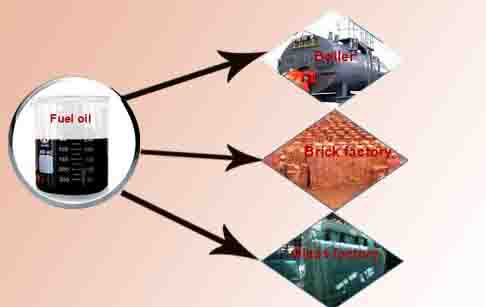

Fuel oil usage

1. Fuel oil: Fuel oil is mainly used in steel plants, boiler heating, heavy oil generators, and cement plants.

Carbon black usage

2 Carbon black: It is mainly used for pressure ball combustion and refined milling. Refined flour can be used for new tires, rubber soles, and pigments.

3. Steel wire: Mainly used for waste recycling and recasting.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email:oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com

http://www.doinggroup.com

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: European Union

- Founded Year: 1987

- Address: Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Province, China

- Contact: Boinne Zhao