Convert waste tire to oil pyrolysis plant

Product Quick Detail

- FOB Price

- USD $50,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard wooden cases pacakges

- Delivery

- 15 Days

Specifications

Convert waste tire to oil pyrolysis plant

The traditional method of disposal of waste plastics is landfill or combustion, this way of dealing with waste plastics is very unscientific. In the destruction of plastic waste, this approach will once again cause serious pollution to our environment. DoingGroup for waste plastics difficult to deal with this social problem, the first to develop awaste tire to oil pyrolysis plant

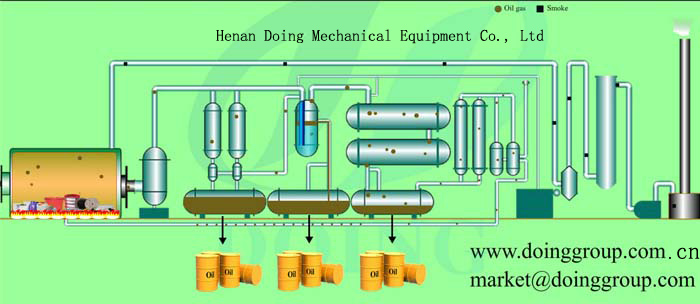

Convert waste tire to oil pyrolysis plant working process

The working principle of thewaste tire to oil pyrolysis plant

1. The waste tires into the automatic push device, into the reactor.

2. Through natural gas or heavy oil and other combustibles, heating the reactor, such as temperature reaches a certain level, we can crack the tire, separating the oil and gas and steel wire.

3. Cracked hydrocarbons through the condensing system, liquefied into heavy oil, into the tank. Some are not liquefied will be filtered again through the condensing system.

4. After the dust deodorant device, is the ultimate fuel.

5. The reactor cooled to 40 degrees below, remove the wire and carbon black.

Many success project cases have proved thatwaste tire to oil pyrolysis plant

Fuel oil application

1. Fuel oil: Can be used in steel mills, boiler heating, heavy oil generators, cement plants.

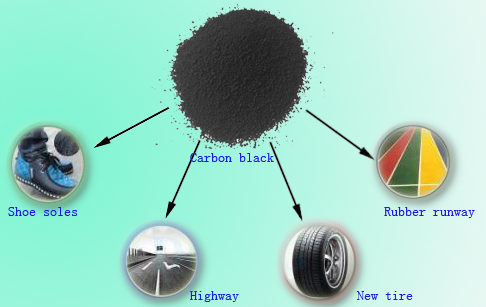

Carbon black application

2. Carbon black: can be used for pressure ball burning and refining flour, refined flour and can be used for new tires, rubber soles, pigment manufacturing materials.

3. Steel wire: mainly used for scrap recycling and re-casting.

4. Combustible gas: Equipment will be recycled again, for reactor heating.

So ourwaste tire to oil pyrolysis plant

1. Reactor steel using Q245R steel, 16mm after the boiler plate for steel. The advantage of this plate is able to withstand high temperature, high pressure.

2. For the welding process we strive to be perfect, using a high standard 3-step welding process, this process is characterized by not easy to crack, long service life.

3. Heating system design has insulation layer, to ensure that the temperature is not easy to lose, save heating energy.

Have you got a better understanding of ourwaste tire to oil pyrolysis plant

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email:oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com

http://www.doinggroup.com

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: European Union

- Founded Year: 1987

- Address: Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Province, China

- Contact: Boinne Zhao