Pyrolysis plant convert waste tire to oil

Product Quick Detail

- FOB Price

- USD $50,000.00 / Piece

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- Standard wooden cases pacakges

- Delivery

- 15 Days

Specifications

Pyrolysis plant convert waste tire to oil

Waste tires are a common type of household waste deposits. If we do not conduct timely and effective treatment, it will cause great harm to our living environment. Based on this social issue, DoingGroup pioneered the development ofwaste tire pyrolysis plant

Waste tire pyrolysis plant

1. The waste tire after automatic push device, into the reactor.

2. The reactor is heated to a certain temperature, waste tires will be cracked into oil and gas.

3. After passing through the condensing unit, these hydrocarbons will be directly liquefied into fuel and flow into the oil tank. The other part will undergo filtration through the condensing system to maximize the liquefaction of oil and gas.

4. The resulting fuel after dust deodorization device, that is, we finally want the cracker oil.

5. Wait until the temperature of the reactor drops below 40 degrees, and then remove the inside of the carbon black, steel wire.

Knowing the waste tire workflow, you may be interested in the benefits of ourwaste tire pyrolysis plant

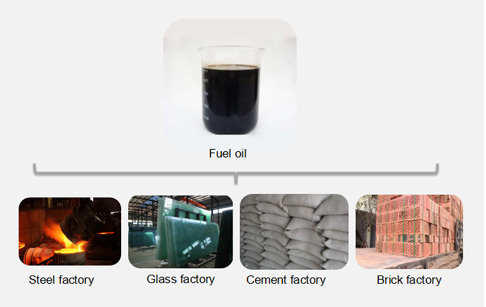

Fuel oil usage

1. Fuel oil: Mainly used in steel plants, boiler heating, heavy oil generators, cement plants.

2. Carbon black: Mainly used for pressure ball burning and refined milling. Which refined flour and can be used for new tires, rubber soles, pigments manufacturing materials.

3. Steel wire: There are two main uses Waste recycling and re-casting.

Pyrolysis plant convert waste tire to oil

The reason why DoingGroup\'swaste tire pyrolysis plant

1. Our pyrolysis reactor with Q245R steel, 16mm thick boiler-specific steel and curved compression head, can withstand high temperature and pressure.

2. High-standard 3-step welding process, not easy to crack, long service life.

3. Double insulation system, reactor heat is not easy to lose, the heating effect is better.

4. Pinion rotation device, power is small, do not directly contact the reactor, less heat transfer, not easy to deformation.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email:oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com

http://www.doinggroup.com

- Country: China (Mainland)

- Business Type: Manufacturer

- Market: European Union

- Founded Year: 1987

- Address: Room 1408, 14th Floor, Building 9, No.133 Yaozhai Road, Jinshui District, Zhengzhou City, Henan Province, China

- Contact: Boinne Zhao