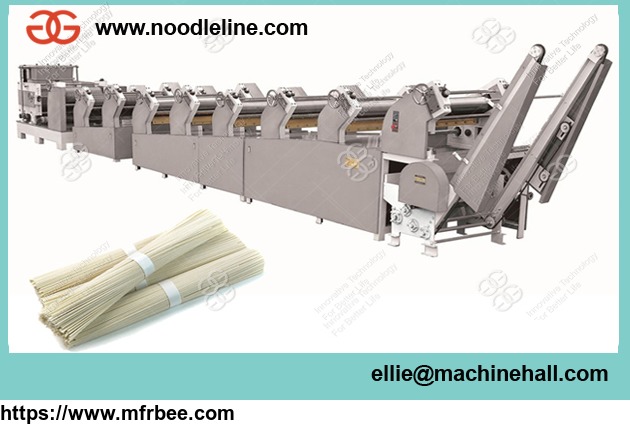

Automatic Egg Stick|Dry Noodles Making Machine Production Line

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- 1 set each wood case

- Delivery

- 30 Days

Specifications

Description:

This dried stick noodles production line overcomes the uncontrolled factors in the natural drying process of handmade dry noodles, combining the traditional craft with modern technology, form a high degree of automation, high efficiency, stable and reliable product quality of noodle production line.

Stick noodle production line

1), Mixer & Ripen conveyer

2), Continuous vacuum dough mixer

3), Continuous vacuum noodle extruding

4), Paste ripen conveyer

5): Continuous rolling machine

6), Length fix cut off & Hanging machine

7), Automatic hang loading machine

8), Noodle end reshaping cutter

9), Drying conveying machine

10), Automatic unloading machine

11), Hot air circulate system

12), Cutting machine

Advantages: The production line is of advanced technology, high degree of automation. safety and reliability ,easy maintenance, high efficiency, and energy saving ,environmental protection and health .meet the technological requirements of producing different varieties of noodles, high quality noodles can be produced under all types of weather conditions.

The finished noodles’ features:

1. Soft---It is up to the manual noodles standard, soft but not sticky.

2. Fragrant---The finished noodle is faint yellow and is delicious.

3. Smooth---The boiled noodle tastes smooth and soft.

4. Flexible---The noodle is flexible and tough.

Data:

| No. | Equipment Name | Remark |

| 1 | Measure and Feeding Machine | Pump 0.75kw Volume 110L |

| 2 | Double Shaft and Speed Mixer | Motor power 6.5/8kw 150kg/batch |

| Falling Powder Bucket | Stainless steel | |

| 3 | U Type Dough Ripening Machine | Power: 4kw 200kg/batch 1600*800*750 |

| 4 | Compound Dough Rolling Machine | Slitting width 350mm power 5.5kw+5.5kw, 7pairs steel roller |

| 5 | Hanging Stick Supplying Machine | Power 1.5kw (frequency control) |

| 6 | Noodle Cutting Tidy Machine | Power 1.1kw |

| 7 | Hanging Rising Machine | |

| 8 | Chain Plate Drying Machine | Main power 3kw industrial fans 0.75 kw×3 sets |

| 9 | Sideway Hang Down Machine | Power 1.5kw |

| 10 | Automatic Hob Cutting Machine | Noodle length: 120~290mm, power 0.8kw. |

| 11 | Electric Control System | frequency control PLC control |

| Total | Total Power ~75kw |

- Country: China (Mainland)

- Business Type: Frying machine.deoiling machine.chin chin making machine,French fries production line,banana chips making line,peanuts coated machine

- Market: Africa,Asia,Europe,Middle East,Americas

- Founded Year: 2010

- Address: No.1-130 9A Area Hardware Electrical And Mechanical Market South China City

- Contact: Xu Ellie