Ceramic Lined Composite Steel Pipe

Product Quick Detail

- Minimum Order

- 1

- Place Of Origin

- China

- Packaging

- in wooden boxes

- Delivery

- 15 Days

Specifications

Features:

Corrosion resistant: Corundum is a neutral material, and is acid-proof and fouling -free.

Heat resistant: The pipe can work under circumstances of -50 to 800 degrees Celsius.

Convenient installation: It is much lighter than any other types of composite pipes, and can be welded or connected through flanges.

Cost effective: Ceramic-lined composite steel pipe can take the place of expensive stainless steel, titanium, nickel, cast stone or alloy pipes. Extended service life can also reduce maintenance cost.

Specifications:

- Pipe diameters: 50 to 630mm

- Elbow angle: 22.5, 45, 60, 90, 120, 135, 150 degrees, etc.

- Three way pipes: Y shaped, Y lateral and other special shapes

- Four way pipes: straight cross, reducing cross.

- Ceramic lining thickness (including transition layer): 3 to 8mm

- Ex-works length: less than or equal to 3m. Customized maximum length can be achieved by welding.

Technical performance parameters Ceramic Lined Composite Steel Pipe

Ceramic Lined Composite Steel Pipe is our continuous improvement after years of study introduced new wear-resistant pipes , the main technical performance parameters have the following:

Good wear resistance

Ceramic wear lining layer of the pipe due to the corundum ceramics (a-AL2O3), equivalent to 9.0 Mohs hardness up to HRC90 or more. So for metallurgy, electric power , mining, coal transportation and other industries grinding media have high wear resistance. Confirmed by the industrial operation : it is ten times the wear life of hardened steel or even several times .

Run a small resistance

Due to the inner surface of the pipe ceramic wear smooth, and never rust , not like the convex surface of seamless steel helix exists. After internal surface roughness of the test unit and water resistance characteristics of the test , the inner surface smoothness better than any metal pipes, clearing a drag coefficient of 0.0193 , slightly lower than seamless . Therefore, the tube has a running resistance and other characteristics , can reduce operating costs.

Corrosion-resistant, anti-fouling

Since the ceramic wear steel pipes ceramic layer (a-AL2O3), a neutral character. So with acid and seawater corrosion resistant , and also has anti-scaling and other characteristics.

We can also provide products of other customized sizes at your demand.

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:Americas,Asia,Europe,European Union

- Founded Year:20000

- Address:No. 273, Siping Road, Shanghai

- Contact:sum xu

You may also like

Other products from Sunny Steel Enterprise Ltd.

Relate products of Ceramic Lined Composite Steel Pipe

The stainless steel spiral welded pipe unit adopts front-swing intermittent production, which is a complete set of spiral steel pipe manufacturing machine integrating machinery, electrical automation control and hydraulic control. SPECIFICATION OF STAINLESS STEEL SPIRAL WELDED ...

Hebei tianxianghao metallurgical equipment manufacturing co.,ltd

The main function of plastic coated brake pipe anti-corrosion production line is to use the oxide layer on the resin surface to bond the steel pipe wall, and add an organic acid as a curing agent to the steel pipe matrix to produce a coating with good corrosion resistance after ...

Hebei tianxianghao metallurgical equipment manufacturing co.,ltd

A high frequency pipe welding machine is a system used for manufacturing steel pipes with high-frequency welding technology. The welded pipe production line typically includes equipment such as an uncoiler, accumulator, forming mill, solid-state welder, sizing mill, flying ...

Hebei tianxianghao metallurgical equipment manufacturing co.,ltd

An anti-corrosion and insulated internal pipe coating equipment production line is a specialized system used for manufacturing steel pipes that are resistant to corrosion and have insulation properties. This internal pipe coating equipment typically includes equipment such as ...

Hebei tianxianghao metallurgical equipment manufacturing co.,ltd

The 3LPE Anti-corrosion Steel Pipe Production Line China is a specialized system used for manufacturing steel pipes with a triple-layer coating designed to resist corrosion. This production line is specifically designed to provide efficient and accurate production of 3PE ...

Hebei tianxianghao metallurgical equipment manufacturing co.,ltd

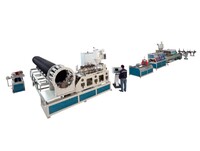

As a leading pipe extrusion machine line supplier, Jwell provides quality composite pipe extrusion production lines for RTP. RTP (Reinforced Thermoplastic Pipe) is a new type of pipe that combines the unique advantages of thermoplastic(PE80, PE100, PA, PER, PVDF, etc), such as ...

Brief Introduction of Steel-plastic Composite Pipe 1. Executive standard: GB / t28897-2012 2. Application: transportation of drinking water, hot and cold water, fire water, drainage, air conditioning water, medium and low compressed gas, compressed air and other media 3. ...

Cast basalt line steel straight pipe is composed by lined with cast basalt pipe, outside steel pipe and cement mortar filling between the two layers. It combines the advantages of cast basalt and steel pipe, wear resistance, corrosion resistance, anti-high-pressure, ...

Cast basalt lined steel pipe ash handling with flange and coupling is composed by lined with cast basalt pipe, outside steel pipe and cement mortar filling between the two layers. It combines the advantages of cast basalt and steel pipe, wear resistance, corrosion resistance, ...

The excellent performance of cast basalt lined steel pipe tee is that it sets tenacity of steel pipe abrasive resistance of cast basalt pipe concreteness of commemorator one. This greatly improves the products adaptive capacity of complicated operation conditions. At the same ...