Customs Plastic Gear Mould Name:Custom Plastic Gear Mould Part Material:POM Product Size: Product Description Plastic Motor Gear Mould Cavity 2 cavities Mould Size 250*250*290 MM Suitable Injection Machine Mould Cavity Steel 2343ESR... Gear Mold Mould Name:Custom Plastic

HANKING MOULD ENGINEERING LTD. [2020-04-14 09:55:08 ]

2k moulding definition HanKing Mould is an ISO9001 2015 certificated factory focusing on developing and manufacturing two shot plastic closure mould for house hold products. HanKing Capabilities 1. Please Injection Mould... Two Component Toothbrush Plastic Injection Mould standar

HANKING MOULD ENGINEERING LTD. [2020-04-14 09:53:32 ]

Plastic Mould Trial In our trial shop, we have 7 injection molding machines with a clamping force ranging from 25 T–250 T including one new vertical machine(120T), we can provide professional mold trial and injection molding service, the machines are focused on mold trials and

HANKING MOULD ENGINEERING LTD. [2020-04-14 09:52:11 ]

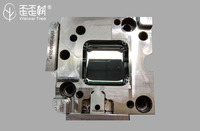

Mainly for injection molding, the cavity pressure should be considered as small as possible when designing the runner and the parting surface. Since the BMC material cannot be decomposed, we are the first to use the materialless handle structure in China. Vacuuming structure, the

ZHEJIANG AOBANG TECHNOLOGY CO.,LTD [2020-04-13 17:09:47 ]

Mainly for injection molding, the cavity pressure should be considered as small as possible when designing the runner and the parting surface. Since the BMC material cannot be decomposed, we are the first to use the materialless handle structure in China. Vacuuming structure, the

ZHEJIANG AOBANG TECHNOLOGY CO.,LTD [2020-04-13 17:09:29 ]

BMC/SMC Moulding Description We mainly use injection molding and pressure molding as the methods. When designing the flow channel and parting surface, we think that the cavity pressure should be as small as possible, especially some small ribs, as well as the smooth exhaust, the

ZHEJIANG AOBANG TECHNOLOGY CO.,LTD [2020-04-13 17:09:11 ]

Auto Parts Mould Injection molding and pressure molding are the main methods. When designing the flow channel and parting surface, the cavity pressure should be as small as possible, the exhaust should be smooth, the discharge position, shape, and material flow direction should b

ZHEJIANG AOBANG TECHNOLOGY CO.,LTD [2020-04-13 17:08:22 ]

We have magnetic materials for sale D ifferent types of magnetic materials Sintered Neodymium Magnets Sintered neodymium magnet is the strongest magnetic material commercially available today. It is largely made of alloy of neodymium, iron and boron, and the chemical formula is N

Huatai Xinding(Beijing)Metal Materials Co., Ltd. [2020-04-13 14:16:01 ]

1.Key frame uses special PC / ABS plastic. 2.Keys are made by secondary injection molding and words will never fall off, never fade. 3.Conductive rubber is made of natural silicone-corrosion resistance, aging resistance. 4.Circuit board using double-sided PCB (customized), contac

余姚翔龙通讯实业有限公司 [2020-04-10 15:49:37 ]

product details (1) uses powder metallurgy, diamond catalyst, electronic components, injection molding, superhard materials, binder, microwave absorbing materials, cemented carbide, superhard materials, and high-end hardware tools. (2) the product has onion like or spherical part

Beijing Metallurgy and Materials Technology Co., Ltd [2020-01-13 11:31:38 ]

two color injection molding machine With major and minor two injection components, can inject synchronously or alternately through the professional computer controlling two screw bars. So as to get the plastic products with beautiful color;

Ningbo beilun highsun machinery co.,ltd [2020-01-07 15:33:39 ]

Take-Out Robot Arm Manufacturer in China Sprue Take Out Robot Arm, Pick and Place Linear Robot Arms for Plastic Injection Molding Machine Automation. Key Specifications/Features Robot Arms are extensively used for pick and place or sprue take out. - Facilitate human-machine colla

Runma Injection Molding Robot Arm Co., Ltd [2019-12-12 12:10:45 ]

Pick & Place Robot Arm Manufacturer from China High-speed Pick & Place Robot Arms for Plastic Molding Machine to increase molding productivity, reduce errors. High-speed pick and place robots are applicable to many types of horizontal injection machines and vertical injection mol

Runma Injection Molding Robot Arm Co., Ltd [2019-12-12 12:02:10 ]

Traverse Robot Arm Manufacturer from China Traverse Robot Arm for Plastic Injection Molding to increase productivity, reduce manual errors and cut costs. The economical series traverse robot is designed for use on horizontal injection molding machines. It is ideal for molded part

Runma Injection Molding Robot Arm Co., Ltd [2019-12-12 11:59:59 ]

Application Injection-molding processing, High surface performance,Mirror polishing can be used for watch accessories and other Aesthestic Ceramics. Type Zirconia ceramic components. Material: Zirconia Available Color White & Black Feature High Wear-resistance,High perfomance,

Shanghai Sencer Precision Ceramics Co.Ltd [2019-12-10 13:48:18 ]

Model NO. nylon injection mol Machining Injection Mould Surface Preparation Customized Certification CE, RoHS, ISO 9001 2000, ISO 9001 2008, ISO, SGS, Other Third Party Test Certification Other Material HDPE,UHMW-PE,PA,Nylon,Mc Nylon,POM, ABS,PMMA,PPS,P Transport Package Plastic

shenzhen Best Technology co,Ltd [2019-11-10 21:10:12 ]

Plastic Injection Molding Our process is simple and usually completes the first batch of products in less than 15 working days. We generally use aluminum molds to better provide a highly efficient production cycle. We specialize in the production of high quality plastic injection

shenzhen Best Technology co,Ltd [2019-10-29 10:48:54 ]

Mold components carbide punches and dies bushings nozzles extrusion dies cutting tools precision ceramic parts JLS Precision Mold Parts Co., Ltd has been devoted to producing precision carbide components for more than 20 years. Our product scope covers precision carbide punch, bu

Dongguan JLS Precision Mold Parts Co.,Ltd. [2019-09-10 09:39:54 ]

JLS Precision Mold Parts Co., Ltd has been devoted to producing precision carbide components for more than 20 years. Our product scope covers precision carbide punch, bushes, tungsten rod, ejector pin, stamping mold, motor connector stamping mold, etc. Tungsten Carbide Mold Compo

Dongguan JLS Precision Mold Parts Co.,Ltd. [2019-09-10 09:25:44 ]

Place of Origin Jiangsu, China Brand Name Shengtai Model Number OEM-12 Plastic Modling Type Injection Color As you require Material PC Product name Plastic Electronic Enclosures Parts Application Routers And Switches Certification ISO9001,IQNET Sample Available Logo Can be custom

Jiangyin Shengtai Electric Appliance Co., Ltd [2019-08-21 13:43:22 ]