Multi-component molding is a highly efficient and cost-effective technology that enables the molding of custom plastic parts using two or three plastic resins or colors in a single operation, resulting in faster cycle times and flash-free products. As a leading expert in this tec

Packson Mold Co., Ltd [2023-10-25 09:59:26 ]

We have several years of experience of trading with customers from the whole world by our serious and responsible working attitudes and professional services. We are continuing to improve our quality of product and service, based on the company policy ‘Best in Class Total Custo

ningbo atlas metal hardware co ltd [2023-10-20 15:00:46 ]

Forbucket and cover mould cooling system design is a relatively complicated work, that is, to consider the cooling effect and the uniformity of cooling, but also to consider the impact of cooling system on the overall structure of the mold; Such as key parts such as moving mold,

JMT Commodity Mould Co., Ltd. [2023-10-19 11:14:29 ]

Etong electric sanitation truck can be widely used in urban sanitation department, property management department, large and medium-sized parks and tourist attractions, golf courses and other entertainment venues, airports, railway stations and other public places, resort and oth

Guang Dong Etong New Energy Technology Co., Ltd. [2023-10-12 16:24:10 ]

custom rubber magnets is one of the ferrite magnet series. It is a soft, flexible and twistable magnet made of bonded ferrite powder compounded with synthetic rubber through extrusion, calendaring and injection molding processes. It can be processed into strips, rolls, sheets, bl

NINGBO SOUWEST MAGNETECH DEVELOPMENT CO.,LTD [2023-10-10 09:47:52 ]

What Is the Difference between Insert Molding and Overmolding Plastic injection molding is one of the most widely used processes for manufacturing high-quality and extremely precise parts. The process is known for its multiple advantages. Consequently, a wide range of industries

Taizhou Huangyan Fow Mould CO., LTD [2023-10-08 17:01:09 ]

Types Of Plastic Injection Mold Polishing Introduction to the plastic injection mold polishing These days, industrial products are developing in the direction of product high quality as well as product diversification, in this way mold quality is going to have an influence on pro

Taizhou Huangyan Fow Mould CO., LTD [2023-10-08 17:00:43 ]

Two shot moulding, also called double shot injection molding, double shot moulding , multi shot injection molding or 2k injection moulding is one category of injection molding using two different thermoplastic materials to produce injection molded parts in two colors or two compo

Taizhou Huangyan Fow Mould CO., LTD [2023-10-08 17:00:11 ]

Keyplast brings every concept into a reality, not only for every client, but also for our own development in all areas, especially in gardening industry and offers products like flower pot making mould and plant pot mould. We specialized in developing our own brands and products,

Taizhou Huangyan Fow Mould CO., LTD [2023-10-08 16:59:29 ]

Over molding of keyplast is a special plastic molding process. Overmolding custom injection molding is similar to the two-color molding or two-shot molding process. Over moulding can make the surface of the product full of softness and increase product functionality and added val

Taizhou Huangyan Fow Mould CO., LTD [2023-10-08 16:59:05 ]

Keyplast has efficient team with many years\' experience of injection moulding, while medical industry is one of our mainly focused industries. With our deep insight into the medical injection moulding industry, MacroMedics approaches to Keyplast for injection moulding service in

Taizhou Huangyan Fow Mould CO., LTD [2023-10-08 16:58:37 ]

Since 1980, Keyplast has involved in different industries and markets for 40 years. As a professional custom plastic parts manufacturer, we have experienced professionals and an efficient team to offer turnkey solutions for different clients and provide custom made plastic parts

Taizhou Huangyan Fow Mould CO., LTD [2023-10-08 16:57:36 ]

Ⅰ. ABS Injection Molding Processing Performance (1) Because of the strong moisture absorption as well as high water content of ABS, the plastic parts that are made of ABS have low gloss and poor internal quality. As a result, ABS injection molding should be dried so that the wa

Taizhou Huangyan Fow Mould CO., LTD [2023-10-08 16:57:09 ]

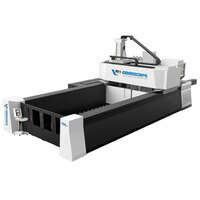

600*600mm large cross-section ram of 5 Axis CNC gantry type machining center to ensure that even when the ram is overhung, the gantry CNC 5 axis gantry type machining center maintains strong cutting rigidity. X/Y axes are each equipped with 4 roller-type linear guides, equipped w

Shandong Deed Precision Machine Tool Co.,Ltd. [2023-10-08 16:23:24 ]

As a China CNC machining medical supplier with over 20 years of experience, ETCN is specialized in offering custom CNC plastic machining services. As the technical CNC machining service supplier, we have various types of CNC processing equipment and testing equipment to help us c

Shanghai ETCN Electromechanical Equipment Co., Ltd. [2023-09-28 14:45:34 ]

As a professional automotive metal stamping and automotive plastic injection molding company, ETCN supplying range can cover architectural sheet metal fabrication, automotive plastic injection molding, car welding and automotive sandblasting on aviation airport ground equipment,

Shanghai ETCN Electromechanical Equipment Co., Ltd. [2023-09-28 14:42:46 ]

Dog Bone Material Testing Dog Bone material test sample testing integrates domestic testing resources, and provides exclusive solutions for profile, steel pipe, plate, stainless steel, structural steel, etc. according to various testing standards including tensile test and variou

KUNSHAN JINLONGYUAN NEW MATERIAL TECHNOLOGY CO.LTD [2023-09-28 14:37:21 ]

Metal injection molding china technology was first used to make some orthodontic appliances in medical treatment. These precision products have very small size, good biocompatibility and corrosion resistance. The main material used is 17-4PH stainless steel. At present, orthodont

KUNSHAN JINLONGYUAN NEW MATERIAL TECHNOLOGY CO.LTD [2023-09-28 14:36:03 ]

Counterweight iron is a process of melting metal into liquid which meets certain requirements and pouring it into the mold. After cooling, solidification and cleaning, the casting with predetermined shape, size and performance can be obtained. Counterweight Block Specifications P

KUNSHAN JINLONGYUAN NEW MATERIAL TECHNOLOGY CO.LTD [2023-09-28 14:34:56 ]

MIM stand for metal injection molding china, it\'s a forming method of a metal parts and can provide a nearly unlimited shape, geometric-feature capability, high-production rates through the use of multi-cavity tooling. Compared with conventional technology like press sintered an

KUNSHAN JINLONGYUAN NEW MATERIAL TECHNOLOGY CO.LTD [2023-09-28 14:33:37 ]