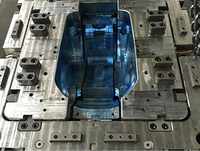

HanKing Mould is an ISO9001 2015 certificated factory focusing on developing and manufacturing a two-shot plastic closure mould for household products. HanKing Capabilities Please Injection Mould Design for two-shot plastic cap & closure. Mould manufacturing for two shot injectio

HANKING MOULD ENGINEERING LTD. [2023-02-14 17:31:32 ]

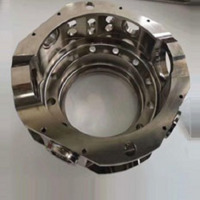

Product material PP material in medical-grade Mold steel S136 HRC 52-54 Mold life 1 million Hot runner brand Incoe Mold base LKM Surface finishing Mirror polishing Mold lead time 6 week What is the plastic injection molding medical parts? Medical-grade polypropylene and medical-g

Unique Solutions Mold [2023-02-06 09:41:25 ]

Medical Moulded Products Different requirements will have different mold steel and products material, USM will choose the mold steel material according to the product requirements and function to achieve zero harm for users, that is the basic standard, including the anti-rust and

Unique Solutions Mold [2023-02-06 09:40:24 ]

Medical Plastic Injection Mold For medical device injection molding companies , it means that medical supervisors are required to supervise and manage the materials used to manufacture the equipment, the medical injection mold parts are designed to withstand high temperatures and

Unique Solutions Mold [2023-02-06 09:39:54 ]

Gas & Water Assisted Injection Mold Since the thermal conductivity and heat capacity of water are much bigger than nitrogen, so the injection cycle of water-assisted is about 70% shorter than the injection cycle of gas assisted injection molding; The product wall thickness of wat

Unique Solutions Mold [2023-02-06 09:38:06 ]

Hot Runner and Cold Runner Mould Generally, the temperature-sensitive wire is composed of steel wire insulated with a heat-sensitive material, the temperature sensing wire is commonly known as the \"thermocouple\", and there are many types, but hot runner thermocouple has two typ

Unique Solutions Mold [2023-02-06 09:34:48 ]

Child safety mouldy car seats are seats specially designed to protect children from injury or death in a collision. The main structure of the child safety seat is a plastic part produced by the child safety car seat mould , and there are also some metal parts to fix or support th

Green Vitality Industry Co., Limited [2023-01-09 11:04:14 ]

Car lights are mainly used for lighting, which can be said to be the eyes of cars. Car lights are the collective name for all car lighting systems. The appearance of automobile lights has high requirements, and several important parts are transparent parts and electroplated parts

Green Vitality Industry Co., Limited [2023-01-09 11:03:58 ]

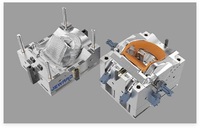

With the vigorous development of the automotive industry, plastic auto part mold is also developing rapidly. 90% of auto parts are produced by injection molds, which is a huge market opportunity for auto plastic parts manufacturers . Common large-size auto parts such as car bumpe

Green Vitality Industry Co., Limited [2023-01-09 11:03:42 ]

The car grille is a mesh part with a grid in the front part of the car. The front grille of the vehicle is located between the front bumper and the front cross member of the vehicle body. Since the hood lock needs to be arranged on the upper surface area of the front grille, the

Green Vitality Industry Co., Limited [2023-01-09 11:03:22 ]

The front and rear bumpers of the car are made of plastic, which not only maintains the protection function, but also has the characteristics of harmony and unity with the body shape, lightweight, and low fuel consumption. The plastic front bumper consists of three parts, namely

Green Vitality Industry Co., Limited [2023-01-09 11:03:03 ]

Green Vitality Industry is a full-service mold manufacturer specializing in plastic injection mold design & engineering support, injection mold manufacturing, and qualifying of plastic injection molds. Green Vitality operates plastic injection molding machines ranging from 80T to

Green Vitality Industry Co., Limited [2023-01-09 11:02:26 ]

With the fast growth in the electronic industry, the demand for injection molding electronics is much higher. The injection molding electronics can be intricate or simple. Intricate injection molding electronics can be economical because they combine many parts into one piece whi

Glitter Mold Technology Co., Ltd [2023-01-06 09:50:00 ]

Decades of accumulation of mould manufacturing technology have witnessed the popularity of electrical plastic molding products. The in mould electronics has been widely applied to various industries. As a result, electronics injection mold manufacturers have been talking about ra

Glitter Mold Technology Co., Ltd [2023-01-06 09:49:44 ]

As the foundation of the automotive industry, injection molding automotive parts are necessary factors to support the sustainable and healthy development of automotive mold manufacturers. In particular, the current independent development and innovation in the automotive parts mo

Glitter Mold Technology Co., Ltd [2023-01-06 09:48:47 ]

2k injection moulding is a manufacturing process that refers to molding two materials or colors into one plastic part. This technology combines two materials or two colors into one ending plastic part by using a 2K automotive plastic injection moulding machine. The selection of t

Glitter Mold Technology Co., Ltd [2023-01-06 09:48:29 ]

Application of Rapid Prototyping in Aerospace Industry Xin Pin is an ISO9001 certificated manufacturer that we can be trusted to handle the aerospace & UAV industries. With our experience, we have a good command of each step of production to undertake your aerospace project produ

Xin Pin Prototype Manufacturing Co.,LTD [2022-12-26 13:57:47 ]

240L GARBAGE BIN MOULD JF32-1 DETAILS Product Description 240L Garbage bin mould Item No. JF32-1 Product Material PP Product Size 720*585*1020mm/680*535*70mm Product Weight 8350g+1034g Total Mould Quantity 2 Moulds Max. Injection Machine Required 2400T Jeward Mould is confident w

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-12-26 11:42:48 ]

Among the three key elements of injection molding industry, material, machine and mould, the plastic injection mould is the most important and changeable one. It brings countless changes to plastic products. And because of the variety of products, processes and materials, the mou

JEWARD MOULD (HUANGYAN) CO., LTD. [2022-12-26 11:40:44 ]

Car Window Mould Automotive Door Bracket Mold can shorten the fixture wasting(the fixture will improve the slight deformation) and it has very good product consistency. The product material is nylon with glass fiber, the product deformation cannot meet the requirements due to the

Unique Solutions Mold [2022-12-15 14:34:22 ]