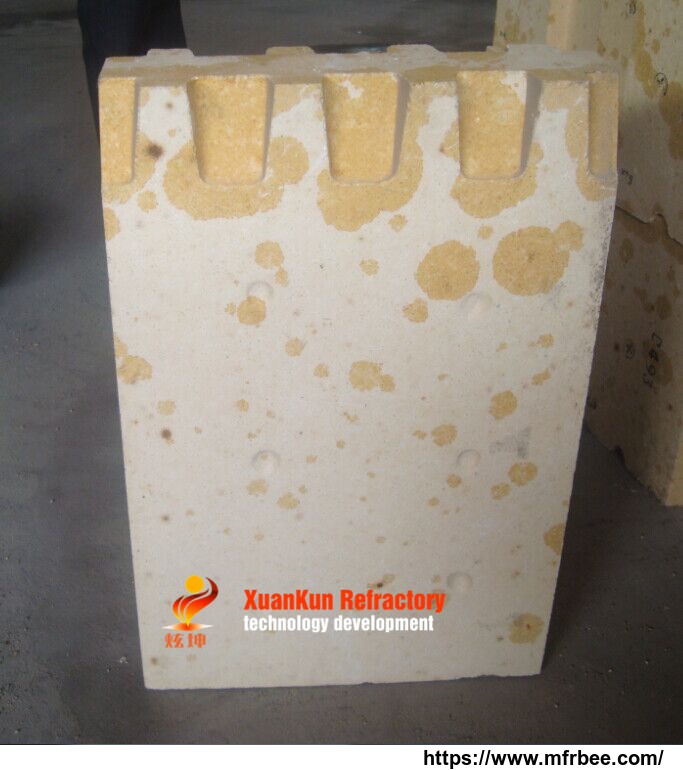

Silica Refractory Brick For Glass Furnance

Product Quick Detail

- Place Of Origin

- China

- Minimum Order

- 1

- Packaging

- as request

- Delivery

- 15 Days

Specifications

Quick Details

Place of Origin: Hebei, China (Mainland)

Shape: Brick

Material: silica stone

SiO2 Content (%): >96%

Al2O3 Content (%): 0.23-0.45

MgO Content (%): 0.8-1.2

CaO Content (%): 0.01

Refractoriness (Degree): 1770°< Refractoriness< 2000°

CrO Content (%): 0.1~0.3%

SiC Content (%): 0.1~1.4%

Model Number: 96A

Brand Name: XUANKUN

Color: Yellow

Size: Customizable

Type: Factory

Bulk Density: 2.0-2.5g/cm3

Certificate: ISO BV SGS

Raw material: SiO2

Fe2O3: 0.5% Max

Advantage: Thermal Shock Resistance

Cold crushing strength(mpa): 40

Introduction of silica brick:

Glass furnace refractory brick silica brick

1.This series of products have natural surface, low water absorption, high bending strength, anti-freeze-thaw, durability etc.

2. Cultural Imitate Clay Split Brick have wonderful tone, natural transition of the changeable colors and special appearance texture makes it natural beautiful, return to the ancient, rustic, steady, what\'s more, you could feel the modern and cultural environment.

3. Environment protects this series of products through very high firing makes the products no impurities, non-radioactive, it\'s green protect product.

4. Beautiful and economical Imitate clay split brick has original clay split brick\'s effect and feature, the products through high temperature firing, so the products not fade, non-anti alkali, low water absorption, what\'s more, with the time development, you will feel the products beautiful view to match the whole building.

Feature of silica brick :

1.Strong acid slag resistance,

2.High refractoriness under load,

3.Volume shrinkage not change when reheated.

4.Used for glass furnace.

Advantage of silica brick :

1.Good acid and erosion resistance, powerful anti high-temperature strength.

2.Soften melting temperature is 1680 °C.

3.Low thermal shock resistance.

4.Natural silica as raw material, plus regular mineralizer.

5.Ensure good bonding and structural strength of furnace.

6.Good heat resistance and long service life.

Application of silica brick :

1. Silica brick is the main refractory bricks used in glass melting furnace;its main crystal phase is Tridymite.

2. Silica brick for glass melting furnace is used in building checker chamber, chute, combustion chamber,coking chamber,and furnace arch etc.

Packaging & Shipping

| Packaging Details: |

Fumigated wooden pallet, using paper or non-woven fabrics between layers separated,plastic shrink film protected outside.finaly using straps. the size of wooden pallet is 95x95cm,95x100cm or as your requirements. |

| Delivery Detail: | 10-30working days after receiving deposit |

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:G20

- Founded Year:1992

- Address:The southern part of Beichengzhai Village, Xingtang Town, Shijiazhuang City, Hebei Province , China (Mainland)

- Contact:Amy Liu

You may also like

Other products from Hebei Xuankun Refractory Material Co.,Ltd

Relate products of Silica Refractory Brick For Glass Furnance

Silica refractory brick is a kind of acidic refractory materials which are mainly made by tridymite, square quartz and a small amount of residual quartz and glass composition. Application: Silica refractory brick is mainly used in lining of coke oven, steel furnace, glass ...