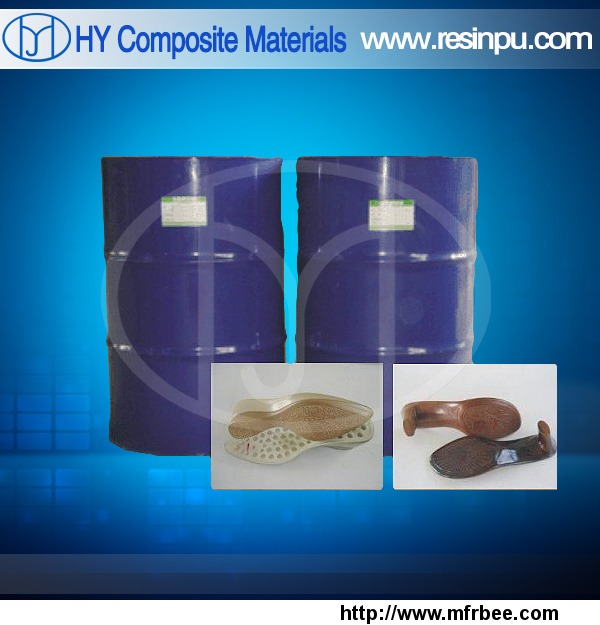

Polyurethane Resin

Product Quick Detail

- Packaging

- 2KG/Set or 10KG/set packing

- Delivery

- 3 Days after payment

Specifications

Description

JA201# polyurethane resin is a polymer material developed material, room temperature curing, two-component, with low viscosity, small odor, soft, transparent glue. For it’s good advantages of Wear resistance, yellowing resistance, UV resistance and never hardens,it is widely used for outdoor application.

Application

1)Used in aviation, railways, construction, sports and other aspects;

2)Surface varnish for wooden furniture and metal;

3)Insulation for storage tanks, pipes, cold storage, beer, fermentation tanks, cold preservation barrels

4)Waterproof for building insulation

5)Used for prefabricated polyurethane sheet

6)For the products making of plastic products, wear-resistant synthetic rubber, synthetic fibers, hard and soft foam products

7) For adhesives and coatings;such as for :all types of wood, chemical equipment, telecommunications equipment and instrumentation and surface finishing of various means of transport, toys, handicrafts, hand model, gifts, etc.

Technical Parameters

| 型号 Code | 比例 Mix Ratio | 收缩率(%)Shrinkage | 硬度 Hardness | 粘度(MPa.s25℃)Viscosity | 混合后粘度 Viscosity after Mixed | 操作时间 Operation times | 耐黄变Yellowing resistance |

| JA201# | A:B=1:1 |

0.02%-0.05% |

20-70A | 600-1000 | 800-1500 | 15-30mins | |

| 1000-2000 |

Characteristics

*Good radiation resistance , yellow resistance and good hardness, it is very suitable for outdoor products

*Good resistant of UV and aging

*Non change hardness, not easy broken, no shrinkage and non deformation ,and good adhensive ,and good sunshine resistance for the long time using

*Low viscosity, and good leveling

Operation instructions

1, Operated under the conditions of ventilation environment.

2, prepare the tools , and make sure it is clean ,dry . Un-oil ,and not contact with any chemical Solvent

3, Weigh part A and part B exactly ( multi-component part A will leads to the bottom of the bubble, multi-component B may cause surface sticky).

4 Carefully stir in the same direction to avoid a large number of bubbles, you need patience and stir until completely transparent.

5, Vacuum Pumping : Vacuum pumping by vacuum machine

Warm tips :

1 The humidity should less than 60% if using by hand , you would better to use a dehumidifier

2 You would better to use metal or plastic tools instead of wooden articles .

3 You should make sure your products is very dry , and can not use inks containing glycerol.

4 This product (especially B glue) can’t contact with skin , otherwise please wash with plenty of water and soap

5 Resin will be cured with High temperature and cured very fast

6 Far away from children to prevent eating.

Package

2KG/Set or 10KG/set packing

Shelf life

Six (6) months when stored under dry and cool place by original package under 25℃

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:2006

- Address:

- Contact:Raemon Shi

You may also like

Other products from SHENZHEN HONG YE JIE TECHONOLOGY CO., LTD.

Relate products of Polyurethane Resin

Provides multi-purpose adhesive cement dental, including Dual Cure cement resin, which could be used with pre-treatment products and offer high bonding strength, also RMGI-Luting cement, which provides a simple and efficient restoration bonding solution. Different Types Of ...

Machines and Materials For Your Needs Eplus3D sla 3d printing machines are available from entry-level models to big size machines for industrial grade rapid prototyping. With the advanced processes for industrial SLA 3D printing with the most various resin materials optional, ...

The material is obtained by grinding the coarse powder (D50 is 13 micron ~ 75 microns). It can be used as moulding material, spraying material and composite modified pre-dispersion. Types of Grade PF PEEK Pure Resin Fine Powder ZYPEEK Supplier PF Series-770PF PEEK Pure Resin ...

With good toughness and impact resistance, Grade G peek pellets can be disinfected using steam, ethvi alcohol and rays, etc. You can see the wide uses of PEEK resin in the medical, pharmaceutical, and food processing industries. Grade G Polyetheretherketone Resin Pellets from ...

Elevator Polyurethane Buffer is a type of safety device installed in elevator systems to absorb the shock and vibration that may be caused by sudden stops or starts of the elevator car during operation. The buffer is typically made of polyurethane, a highly durable and elastic ...

Glycidyl Amine Epoxy Resin is a kind of epoxy resin with glycidyl amine in its molecular chain. These products have various features on dilution ability, glass transition temperature, adhesion, volume shrinkage, and migration. Therefore, they have been widely applied in ...

Cycloaliphatic epoxy resins refer to a series of products obtained by oxidation with butadiene and acrolein as base materials and the mixture of hydrogen peroxide and peracetic acid as oxidant. They have a variety of applications, including 3D printing, coating, ink, adhesives, ...

EP-A650 3D Printer Stereo Lithography is developed by Eplus3D, which is professional in 3D printing technology. The system is user-friendly with high stability, care-free maintenance, and perfect printing results. Feel free to reach out to us to learn more details about the ...

Eplus3D considers materials to be part of its core competency, Eplus3D\'s experienced material department has independently developed a portfolio of resin materials for additive manufacturing. In addition, Eplus3D\'s fully capable material manufacturing is able to control the ...

Resin bonded grinding wheels are generally divided into resin bond diamond grinding wheels and resin bond CBN grinding wheels according to abrasives. E-Grind\'s resin grinding wheels have long service life, excellent self-sharpening ability and good shape retention, high ...