Analysis of energy consumption of pumps under different adjustment modes

Product Quick Detail

- Place Of Origin

- China (Mainland)

- Minimum Order

- 1

- Packaging

- Wooden box

- Delivery

- 15 Days

Specifications

When analyzing the energy consumption under different adjustment methods, the article only analyzes the two widely used adjustment methods: valve adjustment and pump variable speed adjustment. Since the purpose of parallel and series operation of centrifugal pumps is to increase the pressure head or flow rate, it is not widely used in the chemical industry. Its energy consumption can be analyzed in conjunction with Figure 2, and the method is basically the same.

2.1 Power consumption when the valve regulates flow

When the centrifugal pump is running, the power N input by the motor to the pump shaft is:

N=vQH/η

Where N——shaft power, w;

Q——effective pressure head of the pump, m;

H——actual flow rate of the pump, m3/s;

v——specific gravity of fluid, N/m3;

——The efficiency of the pump.

When using a valve to adjust the flow from Q1 to Q2, the shaft power consumed at operating point A2 is:

NA2=vQ2H2/η

vQ2H3——Actual useful power, W;

vQ2(H2-H3)——Power lost on the valve, W;

vQ2H2(1/η-1)——The power lost by the centrifugal pump, W.

2.2 Power consumption when adjusting flow rate with variable speed

When performing variable speed analysis, the proportional law of the centrifugal pump must be used. According to its application conditions, the following analysis indicates that the variable speed range of the centrifugal pump is within ±20%, and the efficiency of the centrifugal pump itself does not change much3. When the electric motor is used to adjust the flow rate to the flow rate Q2, the shaft power consumed by the pump at the working point A3 is:

NA3=vQ2H3/η

The same transformation can be obtained:

NA3=vQ2H3+vQ2H3(1/η-1)(2)

Where vQ2H3——actual useful power, W;

vQ2H3(1/η-1)——The power lost by the centrifugal pump, W.

2.3 Comparative analysis of energy consumption

3.Conclusion

Regarding the two main flow adjustment methods currently common for centrifugal pumps, outlet valve adjustment and variable pump speed adjustment, the energy consumption saved by variable pump speed adjustment is much greater than that of outlet valve adjustment. This can be seen from the power consumption analysis and power consumption of the two. Seen from comparative analysis. Through the relationship between the flow rate and the head of the centrifugal pump, the energy consumption relationship under the two adjustment methods can be more intuitively reflected. Reducing the flow rate through variable speed adjustment of the pump can also help reduce the possibility of cavitation in centrifugal pumps. When the flow rate decreases larger, the energy-saving efficiency of variable speed adjustment will also be greater, that is, the valve adjustment power loss will be greater. However, when the pump variable speed is too large, it will cause the pump efficiency to decrease and exceed the range of the pump proportional law. Therefore, in practical applications, It should be considered from many aspects and the best flow adjustment method can be synthesized between the two.

If you want to know more about slurry pumps, please feel free to call us!

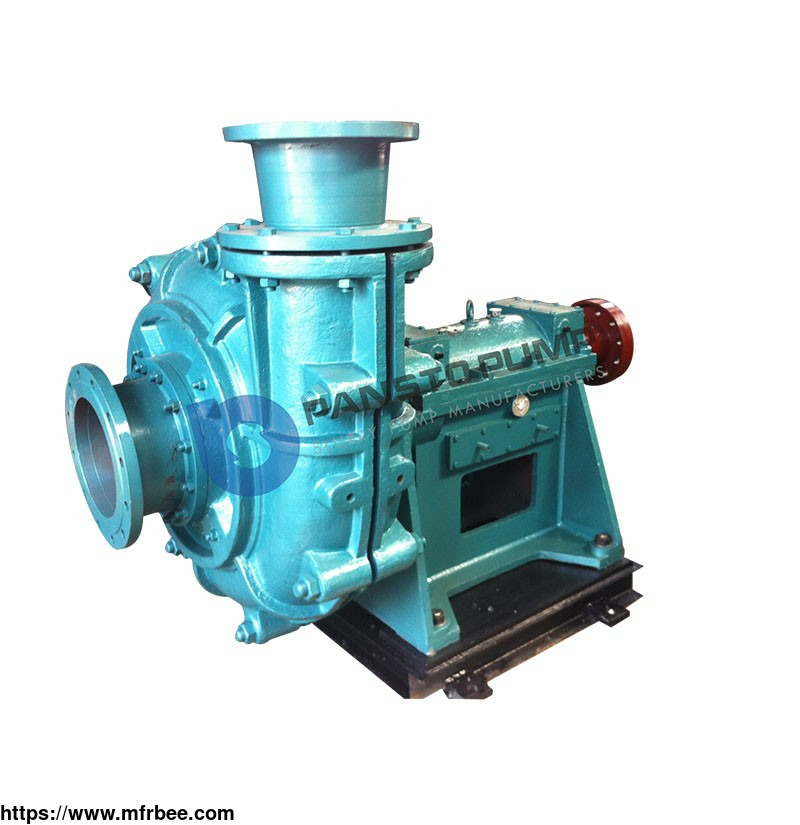

ShijiazhuangPansto Pump Industry is a manufacturer of slurry pumps in Shijiazhuang. It mainly designs, manufactures and sells slurry pumps and accessories. Mainly engaged in mud pumps, submersible pumps, foam pumps, desulfurization pumps and many other series.

Special pump for coal washing Sand and gravel slurry pump High-lift slurry pump Imported slurry pump Heavy-duty slurry pump Horizontal slurry pump Single-shell slurry pump Iron ore tailings pump Tailings slurry pump Slurry circulation pump Lime slurry pump

High pressure slurry pump centrifugal slurry pump

- Country:

- Business Type:

- Market:

- Founded Year:

- Address:

- Contact:Laura Shi

You may also like

- wedding dresses

- bridal wedding dress

- dress wedding gown

- wedding dress bridal

- wedding evening dress

- fashion wedding dress

- style wedding dress

- wedding dress gown

- designer wedding dress

- gown wedding dress

- elegant wedding dress

- lace wedding dress

- popular wedding dress

- bridal wedding dresses

- designer wedding dresses

- quality wedding dress

- wedding dresses bridal

- new wedding dress

- satin wedding dress

- wedding dress