Insert Mold Parts

Product Quick Detail

- FOB Price

- USD $10,000.00 / Piece

- Place Of Origin

- china

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

- Country: China (Mainland)

- Business Type: Manufacturer

- Market:

- Founded Year:2017

- Address:No.136 Xingwu Road,Wusha Community, Changan Town,Dongguan, China

- Contact:usm mold

Other products from Unique Solutions Mold

Relate products of Insert Mold Parts

The Three Part Syringe Plunger from PLUSLINK is a durable and easy-to-use device designed to help inject medication into the body accurately and safely. It is constructed from three separate parts made from medical-grade plastic, allowing for easy maintenance, cleaning and ...

It is designed for various types of three-part syringe barrel.including luer slip, luer lock and dual-structural syringe. (1ml, 2ml, 2.5ml, 3ml, 5ml, 10ml, 20ml, 25ml, 30ml, 50ml, 50ml Catheter Tip, 60ml Catheter Tip, 100ml, 150ml) It consists of three main components: the ...

We are an unparalleled name in offering a wide gamut of precision wire cutting parts. These wire cutting parts are amongst the most desirable and reliable products in the industry. The offered spare parts are manufactured using the best grade raw material under the supervision ...

A thread is a continuous helical ridge formed on the inside (nut) or outside (screw) of a cylinder. This ridge is called the crest. Between each crest is a space, called the root. Threads are set at an angle to the axis of the bolt or nut. We provide quality threaded parts. ...

We provide DIN(Deutsche Industrie Normen) standard mould parts of high quality to our customers. The mold standard parts are applied to all kinds of mold base and mold holders. As a professional precision mold supplier, we will provide good services to satisfy different ...

Stamping — also called pressing — involves placing flat sheet metal, in either coil or blank form, into a stamping press. In the press of stamping components making, a tool and die surface form the metal into the desired shape. Punching, blanking, bending, coining, ...

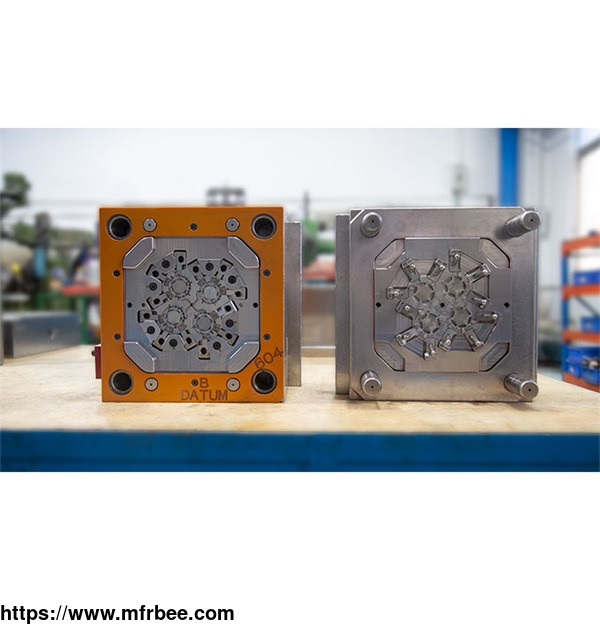

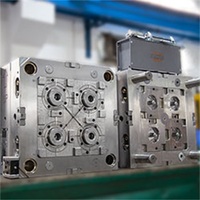

Insert Mold USM molds focus on structural parts injection molds, water-assisted Gas-assisted injection molds, small parts plastic molds, precision plastic molds, and plastic parts product molds, from mold design to mold manufacturing, mold assembly test molds, product injection ...

This shape of a mold is predetermined by a mould, a block that has been hollowed out. Aluminum, steel, alloys, and copper are the most common materials used to build it. It\'s made up of various other mold parts, too. Our mold spare parts include lifters and ejectors as well as ...

Base. Table. Column. Abrasive Wheel. Wheel Guard. Abrasive Wheel Head. Three Types of Traversing Wheels. Coolant Supply Nozzle. DETAILS OF GRINDING PARTS Advantages Of Grinding Parts Precision tolerances Accurate dimensions Smooth surface finish Best material Competitive prices ...