PRECISION PLASTIC INJECTION MOLDS/TOOLS

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

- Country: Afghanistan

- Business Type:

- Market:

- Founded Year:

- Address:"No.10 Hongshi Rd., No.1 Industrial Zone, Lu Dong Management Zone,Humen Town, DongGuan City, Guangdong province, 523935, China"

- Contact:Fangling mold

Other products from Dongguan City Fangling Precision Mould Co., LTD.

Relate products of PRECISION PLASTIC INJECTION MOLDS/TOOLS

When it comes to custom injection molding, precise moulds and precision equipment are required for precision molding or PIM. Among the topics covered in this blog are general ideas, specific traits and qualities, as well as specific options for plastic materials, precision ...

Packson - Medical Plastic Injection Molding Expert Packson sets itself apart from other medical injection molding companies through its distinguished ISO certification for medical injection molding services. Holding certifications for both ISO 13485:2018 and ISO 9001:2008, ...

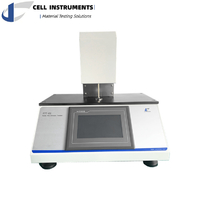

FTT-01 Thickness Tester Background Plastic film thickness is critically important to check as it directly affects product quality, functionality, cost control, regulatory compliance, and customer satisfaction. Maintaining consistent thickness ensures that the film performs its ...

Medical Injection Mold For medical plastic injection molding companies, it means that medical supervisors are required to supervise and manage the materials used to manufacture the equipment, the medical injection molds parts are designed to withstand high temperatures and ...

The equipment we have developed includes: one-step extrusion molding equipment for mixed waste plastic films; two-step extrusion molding equipment for mixed waste plastics; co-directional flat one-step extrusion molding equipment; single-station and double-station extrusion ...

Which Mold do you want to do? Plastic Injection/die casting or punch mold, etc. Which Mould Material do you want choice? 45#, 50#, P20, H13, 718, 2738, NAK80, S136, SKD61, etc. Which does the Product Material want? PP, PC, PS, PE, PU, PVC, ABS, PMMA, etc. How many Cavities? ...

PRECISION PLASTIC INJECTION MOLDING Digital manufacturing for plastic prototypes and on-de-mand production parts. Request an injection molding quote today. Precision plastic injection molding is a manufacturing process for producing parts by injecting molten material into a ...

The injection molding part is replacing metal products in many fields of industrial applications to meet the requirement of lightweight industrial equipment and cost-reduction. Green Vitality has accumulated many experiences over the years in providing a full spectrum of ...

Packson - Medical Plastic Injection Molding Expert Packson sets itself apart from other medical injection molding companies through its distinguished ISO certification for medical injection molding services. Holding certifications for both ISO 13485:2018 and ISO 9001:2008, ...