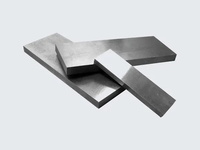

Molybdenum Plate

Product Quick Detail

- Minimum Order

- 1

- Packaging

- N/A

- Delivery

- 15 Days

Specifications

- Country: China (Mainland)

- Business Type:

- Market:

- Founded Year:

- Address:Luoyang CBD, No.288 of Kaiyuan Avenue, Luoyang, Henan, China

- Contact:Longhua com

You may also like

- wedding dresses

- bridal wedding dress

- dress wedding gown

- wedding dress bridal

- wedding evening dress

- fashion wedding dress

- style wedding dress

- wedding dress gown

- designer wedding dress

- gown wedding dress

- elegant wedding dress

- lace wedding dress

- popular wedding dress

- bridal wedding dresses

- designer wedding dresses

- quality wedding dress

- wedding dresses bridal

- new wedding dress

- satin wedding dress

- wedding dress

Other products from Longhua Technology Group (Luoyang) Co., Ltd

Relate products of Molybdenum Plate

Steel plate shot blasting machine is one kind of roller conveyor shot blasting machines. It can remove all rust, corrosion and mill scale from steel plate and provides ideal surface finish (SA2.5) for securing a continuous and effective bond between the steel surface and coat. ...

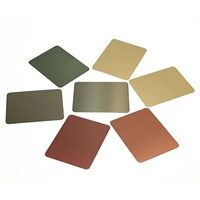

Vibration Silver Plate Sheet Stainless Steel has a textured surface with a silver color. This finish is achieved by using special brushes or rollers to create a pattern of parallel lines. It is commonly used in architectural applications, such as wall panels, elevator ...

Multi-Segment Food Stainless Steel Plate Heat Exchangers These heat exchangers are designed to handle various food products, such as dairy, beverages, sauces, soups, and other viscous or particulate-containing fluids. The multi-segment plate configuration allows for separate ...

Gasketed plate heat exchangers are versatile and efficient devices that facilitate heat transfer between two or more fluids. Their unique design comprises a series of plates with gaskets, forming channels for the fluids to flow through. These gaskets ensure a tight seal, ...

Brazed Plate Heat Exchangers Brazed plate heat exchangers are constructed with a series of thin, corrugated stainless steel plates. These plates are carefully stacked and brazed together using a high-temperature process, creating a sealed unit with alternating hot and cold ...

Etching stainless steel etching plate sheet is achieved by selectively etching the surface with acid or other chemicals to create intricate designs or patterns. It is often used in artistic and decorative applications like nameplates, signs, and artwork. How Do I Clean And ...

Sondex Heat Exchanger Plates Sondex heat exchanger plates excel in their construction quality, efficient heat transfer capabilities, and versatile applications. With their advanced designs and turbulence-inducing features, these plates optimize heat transfer efficiency. They ...

Heat exchanger plates are the key components in plate heat exchangers. These plates are designed with specialized patterns or corrugations to maximize heat transfer efficiency. They provide a large surface area for heat exchange between fluids, ensuring effective and efficient ...

GEA Heat Exchanger Plates GEA heat exchanger plates exemplify excellence in design and engineering. With advanced technological innovations, GEA offers a wide range of plates featuring optimized patterns, efficient heat transfer surfaces, and exceptional material selections. ...

Tranter Heat Exchanger Plates Tranter heat exchanger plates are highly regarded for their industry-leading quality and performance. These plates are meticulously engineered and manufactured to ensure optimal heat transfer efficiency and superior thermal performance. With a ...