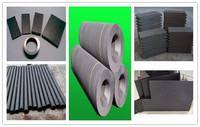

Anode Carbon Block Overview

It participates in electrochemical reactions and directs current into the electrolytic cell. Each prebaked carbon anode block is preassembled by 1 ~ 3 anode carbon blocks, anode guide rod and steel

claw (see anode carbon block assembly). The single anode group is the most common one. The number and size of the carbon block group depends on the capacity and current density of the electrolytic

cell (generally 10 ~ 40 groups).

The carbon blocks are arranged symmetrically on the left and right sides of the anode horizontal bus in the slot, and the aluminum guide rod of the carbon blocks is fixed on the horizontal bus by a

rotatable clamp. The aluminum guide rod plays the dual role of conveying current and hanging the carbon graphite block for cathode.

Anode Carbon Block Uses

Anodes are large carbon blocks which are used to conduct electricity during the aluminum reduction process. Anode material for pre-baked aluminum electrolytic cell. It is composed of several anode

carbon blocks and an anode lifting mechanism. Prebaked anode is an important part of prebaked anodic aluminum electrolytic cell. Anodes are positive electrodes, typically made from crushed calcined

petroleum coke and liquid pitch formed into rectangular blocks and baked. These anode blocks are attached to rods and suspended in an electrolytic cell, where they are slowly consumed in the

aluminum smelting process.

Cathode carbon vs. Anode carbon

1.Different ash content ranges. The ash content of cathode carbon block is between 8% and 15%, and the ash content of cathode carbon block is higher, some even as high as 30%. Therefore, it can be

identified by ash in carbon anode butts and the cathode carbon block are broken into a size of 100mm.

2.Different sectional feature. The main composition of Carbon anode butts is calcined petroleum coke, so its cross section has obvious porous and certain metallic luster, while the cathode carbon

block does not have this characteristic.

Block carbon manufacturing process

1.The carbon block manufacturing process consists of several steps, starting with material approval, approval testing of all materials used in drinking water applications, and testing of the key

performance characteristics of each material prior to the production of carbon blocks.

2.Mix the material before forming or extruding. During the forming process, the material is loaded into the mold, compressed and heated to form a sintered block. After cooling, the carbon block is

removed from the mold. In the continuous forming process, the material is heated in the screw or in the external mold.

3.The characteristics of carbon blocks produced by molding process and extrusion process are similar, and the basic processes are similar. The typical limitations involved in carbon block

manufacturing are related to the production equipment that can be used to produce carbon blocks of a given size. To sum up, carbon block is an effective and widely used filtration method.

Carbon anode aluminium production

During the aluminium reduction process, anodes, as large carbon blocks, are used to conduct electricity. The manufacturing processes of carbon anodes and graphite electrodes are very similar and

overlap in some cases. Anode effect in aluminum production is a phenomenon which the low concentration of alumina in the electrolyte leads to the increase of the resistance of the electrolytic

cell, the instability of the electrolytic cell and the decrease of aluminum output.

Technical specification:

No Item Unit Guarantee Value

1 Apparent Density g/cm3 (min) 1.52

2 Electrical Resistivity μΩ.m (max) 63

3 Compress strength Mpa (min) 30

4 Thermal Conductivity W/mk(max) 4.5

5 Flexural Strength Mpa(Min) 38

6 Permeability NPm(Max) 2.0

7 Thermal Exposure 10-6/k 5.0

8 Ash %(Max) 0.5

9 Fe ppm(Max) 500

10 Si ppm(Max) 350

11 V ppm(Max) 350

12 Na ppm(Max) 500

600mm UHP Graphite Electrode

According to the classification of electric furnace steelmaking power level and the difference of raw materials used for producing Graphite electrodes as well as the physical and chemical indexes

of f...

If you are looking for a reliable carbon block manufacturer, don't hesitate to contact us!

Huaro, as an excellent carbon block manufacturer, offers a wide range of hot rolled steel for you to choose from.